Weaving machine transmission and weaving machine position automatic calibration system driven by switch reluctance motor

A technology of switched reluctance motor and automatic calibration system, used in looms, textiles, textiles and papermaking, etc., can solve the problems of frequent failures of main clutch and main brake, transmission belt breakage, and frequent failure of weft-seeking clutches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

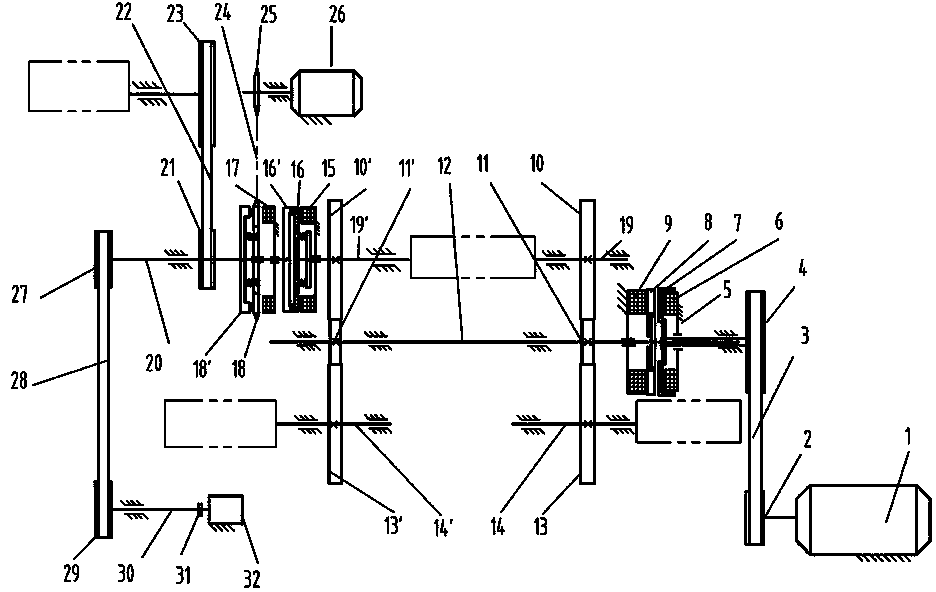

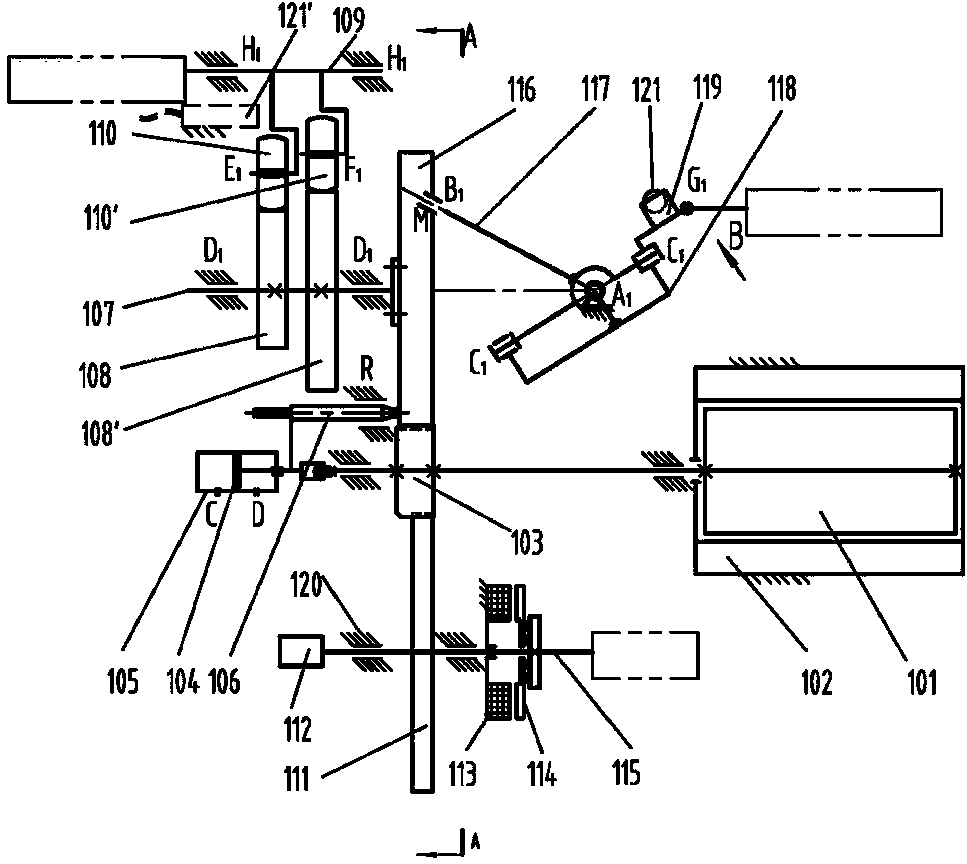

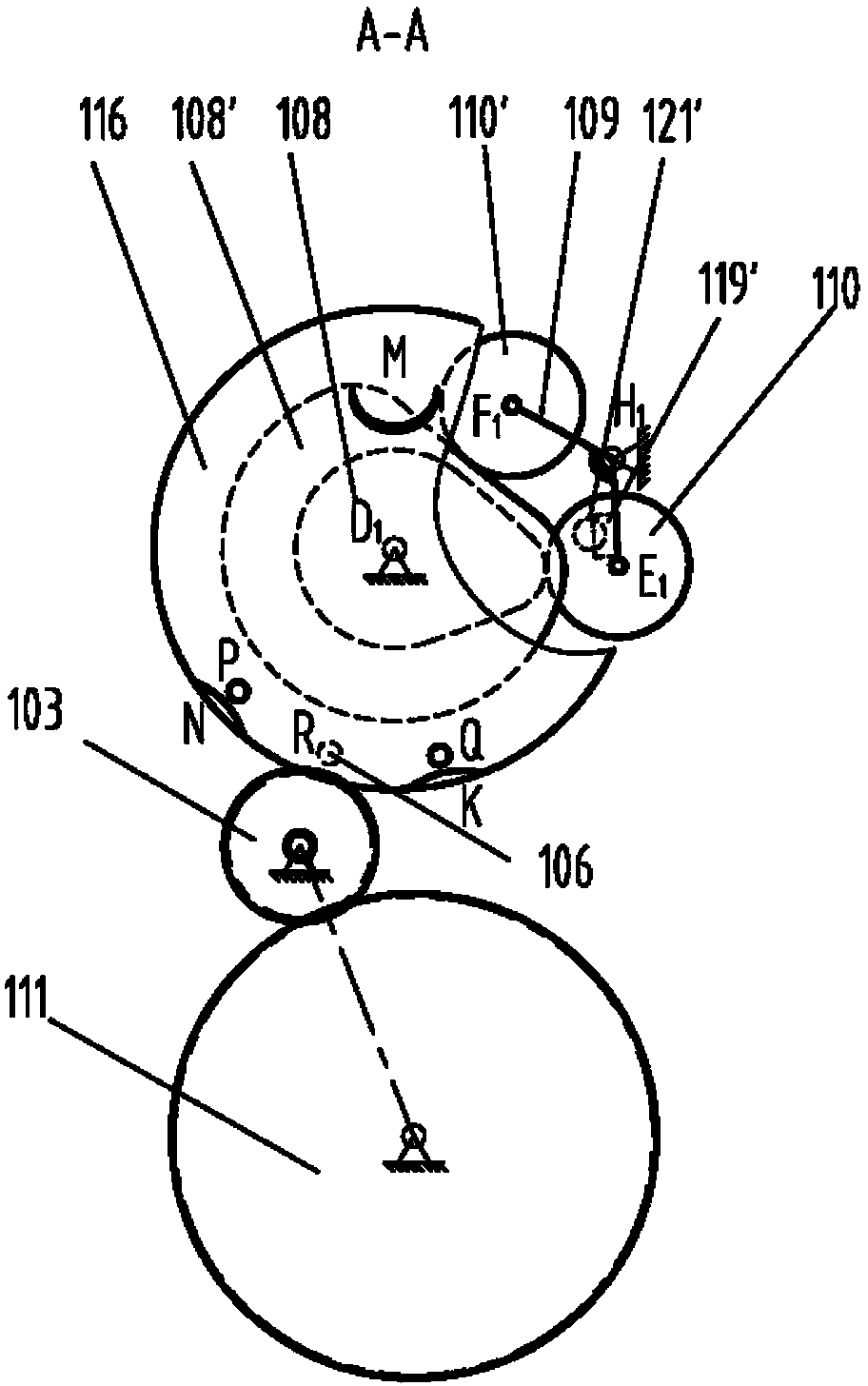

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention is mainly to overcome the deficiencies of the prior art. On the basis of the prior art—the rapier loom drive system driven by the switched reluctance motor, the main clutch, the main Brakes, weft-seeking clutches, idle clutches, etc., cancel the belt drive; see the specific drive system figure 2 -6 shown.

[0030] The loom transmission and loom position automatic calibration system driven by the switched reluctance motor, the motor stator 102 of the switched reluctance motor is fixed on the frame 120, the motor rotor 101 and a main motor supported on the frame 120 through bearings The gear shaft 103 is fixedly connected, and it is characterized in that: one end of the gear shaft 103 of the main motor is connected with a piston 104 through a bearing, and the piston 104 is fixedly connected with a movable pin 106 placed in the guide hole R on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com