Pantograph pan of high-speed railway motor train unit and preparation method thereof

A technology for pantograph sliding plates and high-speed railways, applied in the field of materials, can solve problems such as major accidents in line operation safety, inadequate metal immersion, and insufficient dipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

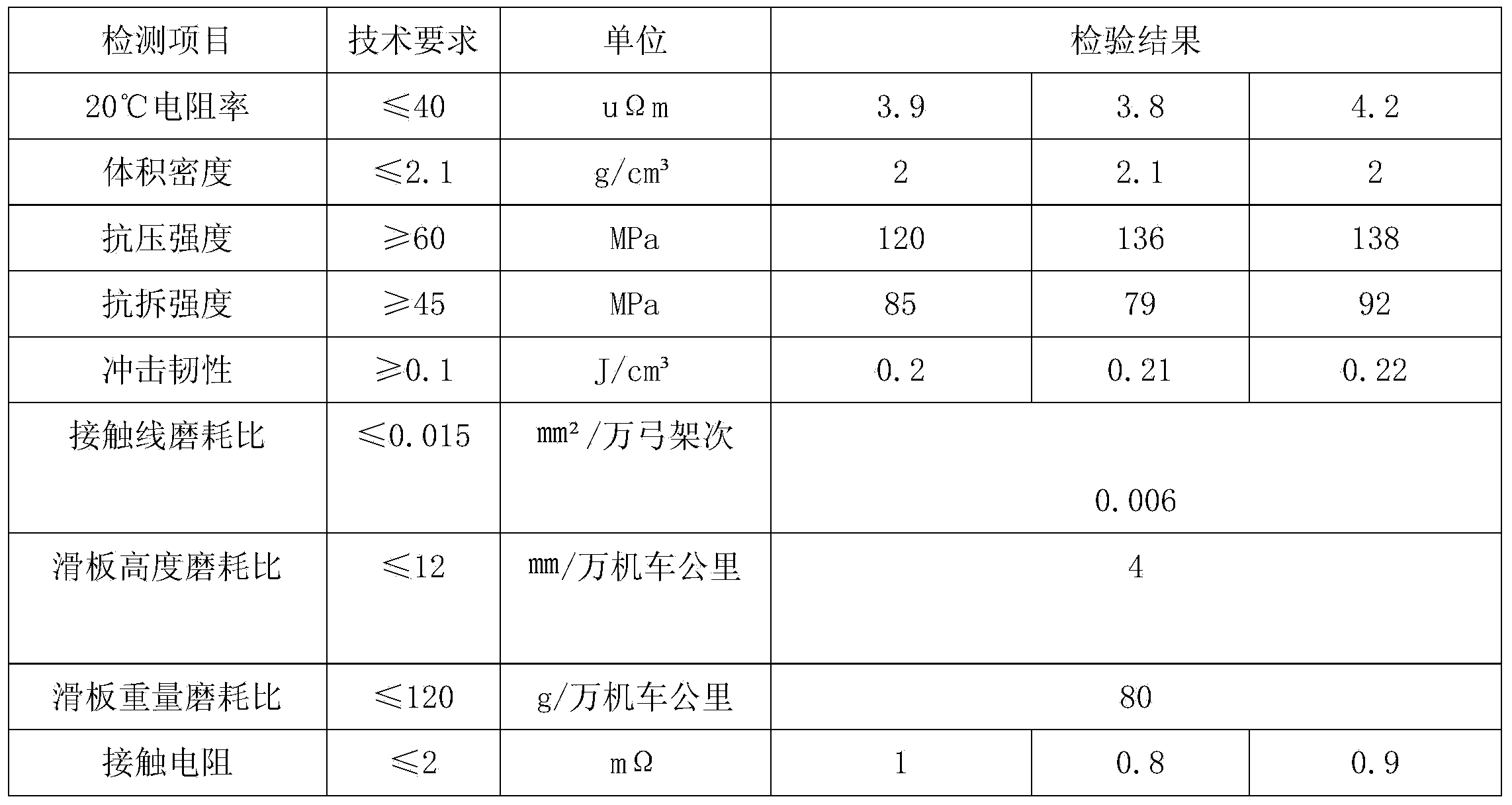

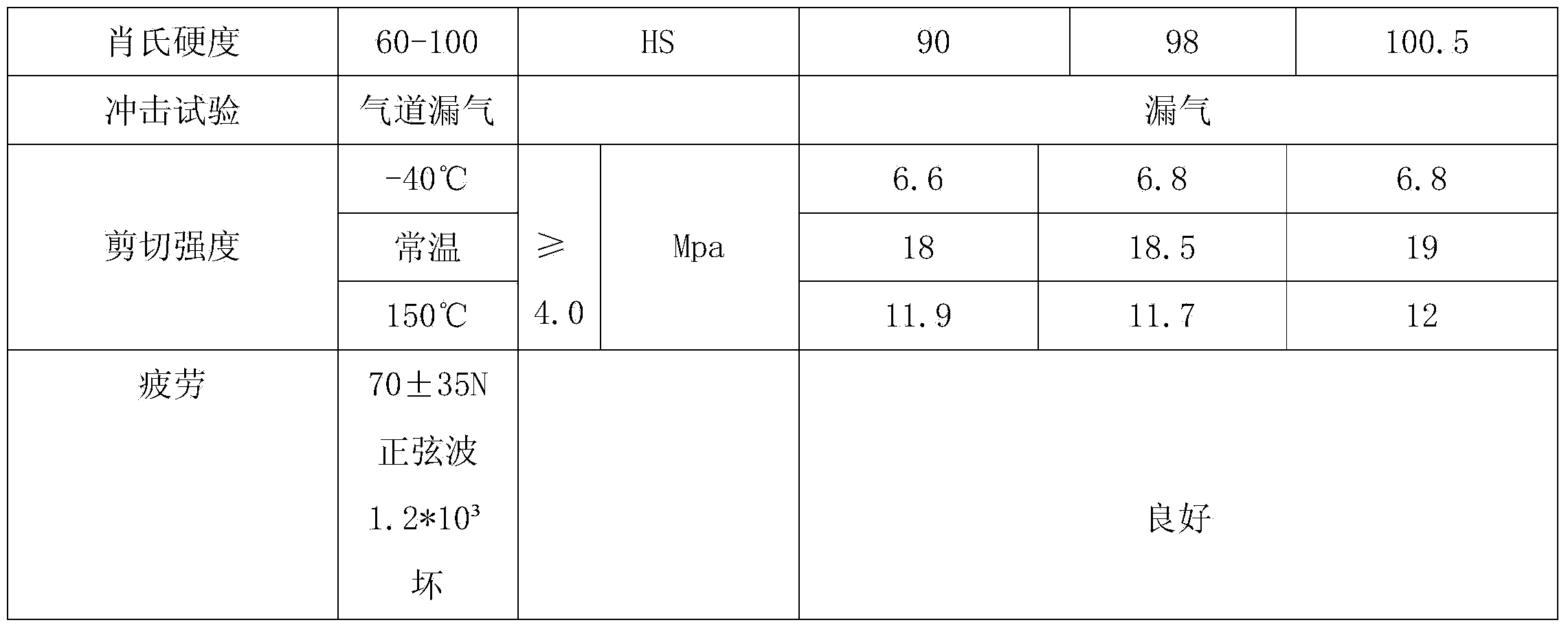

Embodiment 1

[0053] A high-speed railway EMU pantograph slide plate, the main raw materials are as follows: carbon material: 4 parts by weight of pitch coke, graphite: 0.6 parts by weight of electrode graphite 300 mesh, seepage metal: 2.5 parts by weight of copper powder of 8000 mesh, molten pitch: 2.9 parts by weight Parts; Φ0.01mm~0.05mm long 3~12mm carbon fiber 1 part by weight.

[0054] (1) Grind the pitch coke into 50% and 50% of 200 and 400 mesh powders respectively with a 510V internal classification mill.

[0055] (2) Put pitch coke powder, electrode graphite, and seepage metal into a 600-liter 360°C high-temperature twister for metal seepage twisting and stirring (50 revolutions per minute), and dry the moisture in various powders at the same time After twisting and mixing for 60 minutes, add high-temperature molten asphalt glue melted at 300°C and the above powder for metal-wrapped powder-liquid twisting, take it out after mixing for 60 minutes, and then put it into a circular st...

Embodiment 2

[0066] A high-speed railway EMU pantograph slide plate, the main raw materials are as follows: carbon material: 4 parts by weight of pitch coke, graphite: 0.6 parts by weight of electrode graphite 300 mesh, seepage metal: 2.5 parts by weight of copper powder of 8000 mesh, molten pitch: 2.9 parts by weight share. (1) Grind the pitch coke into 50% and 50% of 200 and 400 mesh powders respectively with a 510V internal classification mill.

[0067] (2) Put pitch coke powder, electrode graphite, and seepage metal into a 600-liter 360°C high-temperature twister for metal seepage twisting and stirring (50 revolutions per minute), mixing, and drying of various powders at the same time Moisture, after twisting and mixing for 60 minutes, add high-temperature molten asphalt glue melted at 250-300°C and the above powder for metal-wrapped powder-liquid twisting, take it out after mixing for 60 minutes, and then put it into a round shape of Φ300mm and 500mm deep A 500Mpa hydraulic press is ...

Embodiment 3

[0078] A high-speed railway EMU pantograph slide plate, the main raw materials are as follows: carbon material: 4 parts by weight of pitch coke, graphite: 0.6 parts by weight of electrode graphite 300 mesh, seepage metal: 2.5 parts by weight of copper powder of 8000 mesh, molten pitch: 2.9 parts by weight 1 part by weight of copper fiber with a length of Φ0.01 mm to 0.05 mm and a length of 3 to 12 mm.

[0079] (1) Grind the pitch coke into 50% and 50% of 200 and 400 mesh powders respectively with a 510V internal classification mill.

[0080] (2) Put pitch coke powder, electrode graphite, and seepage metal into a 600-liter 360°C high-temperature twister for metal seepage twisting and stirring (50 revolutions per minute), mixing, and drying of various powders at the same time Moisture (no temperature), after twisting and mixing for 60 minutes, add high-temperature melted asphalt glue melted at 250-300 °C and the above powder for metal-wrapped powder-liquid twisting, mix for 60 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com