Polishing machine with improved adsorption method for polished parts

A polishing machine and adsorption tank technology, applied in the field of polishing machines, can solve problems such as poor air tightness, increased equipment costs, and increased costs, and achieve simplified adsorption and peeling processes, easy adhesion and peeling, and easy loading and unloading The effect of taking the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

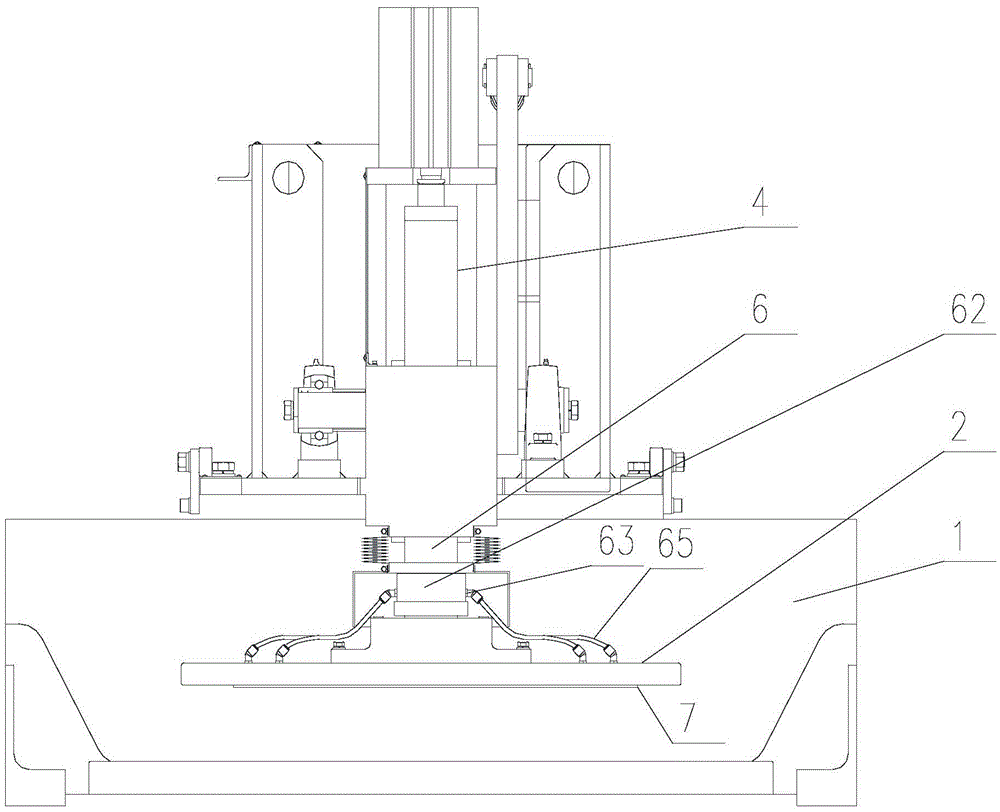

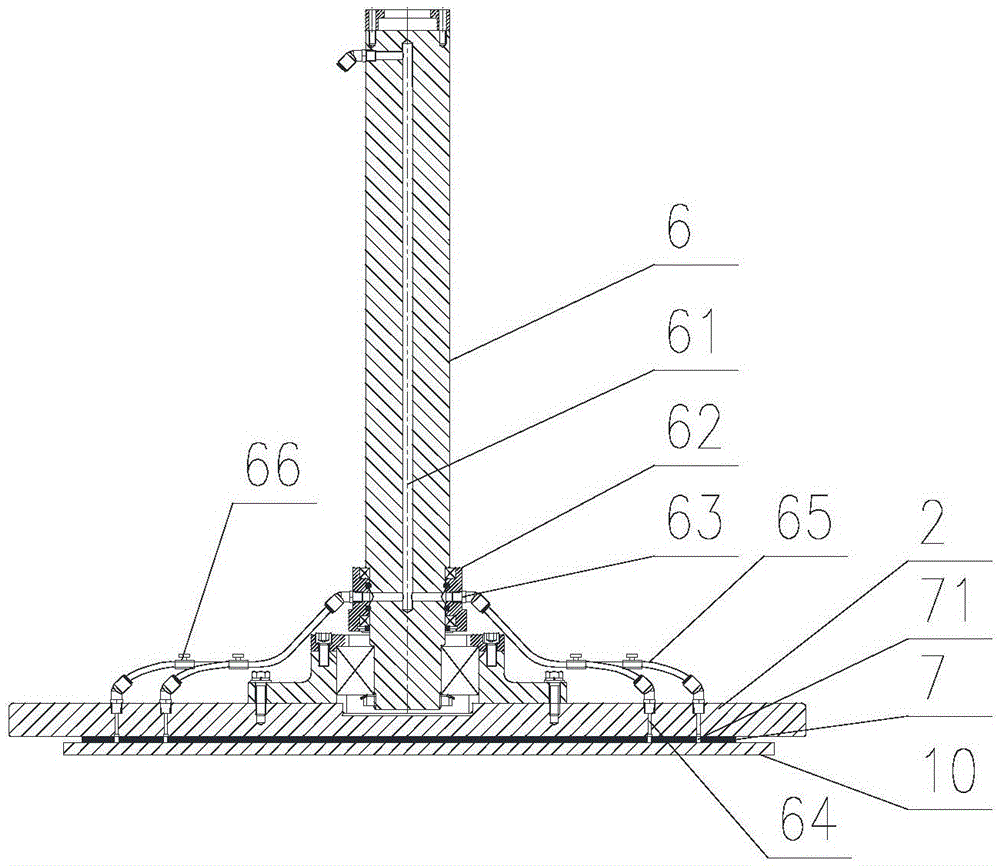

[0033] a kind of like Figure 1 ~ Figure 3 The up-suction polishing machine of the present invention, which improves the adsorption mode of polishing parts, includes a frame 1, an adsorption upper plate 2, an adsorption lower plate 3, an upper plate drive system 4, a lower plate drive system 5, a recovery system and a vacuum system , the upper disk drive system 4 includes a central shaft 6, the bottom of the central shaft 6 is connected with the adsorption upper disk 2, a closed connection air circuit 61 is opened in the central shaft 6, and a rotary air circuit joint is provided near the bottom of the central shaft 6 62. The inner end of the rotary gas path connector 62 is connected to the external vacuum system through the closed connection gas path 61 (conventional vacuum system can be used, not shown in the figure), and the outer end of the rotary gas path connector 62 is set There are a plurality of air passage interfaces 63, and the adsorption upper plate 2 is provided w...

Embodiment 2

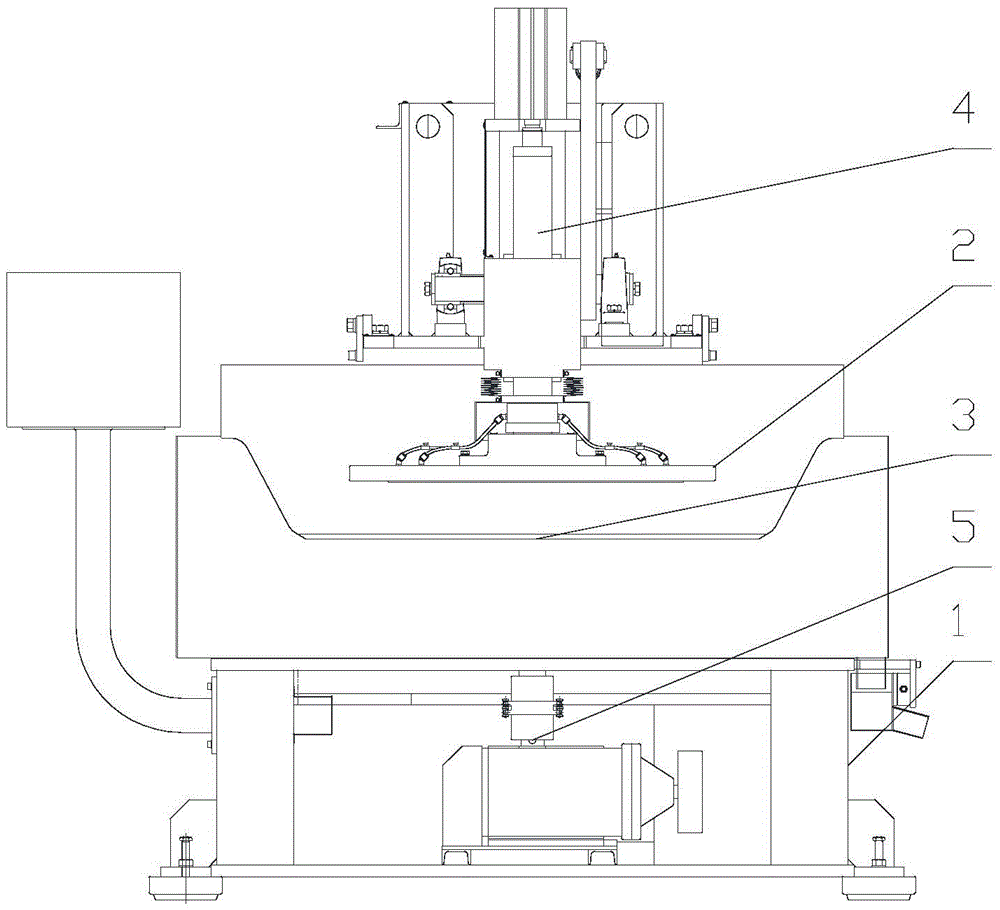

[0039] a kind of like Figure 4 ~ Figure 7 The down-suction polishing machine of the present invention, which improves the adsorption method of polishing parts, includes a frame 1, an adsorption upper plate 2, an adsorption lower plate 3, an upper plate drive system 4, a lower plate drive system 5, a recovery system and a vacuum system (see Figure 7 ), the lower disc drive system 5 includes a central shaft 6, the top of the central shaft 6 is connected with the adsorption lower disc 3, the central shaft 6 is provided with a closed connection air circuit 61, and the central shaft 6 is provided with a rotating air circuit near the bottom Joint 62, the upper end of the rotary air path joint 62 is connected with the bottom end of the closed connection air path 61, the lower end of the rotary air path joint 62 is connected with the vacuum system, and the upper part of the closed connection air path 61 is connected to the outside of the central axis 6. The air path interface 63 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com