Clamping mechanism of line pipe welding edge

A technology of clamping mechanism and line pipe, which is applied in the direction of clamping device, clamping, metal processing machinery parts, etc., can solve the problems of loose clamping of pipe fittings, falling of pipe fittings, large interaction force, etc., and improve the clamping force , improve the service life and ensure the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

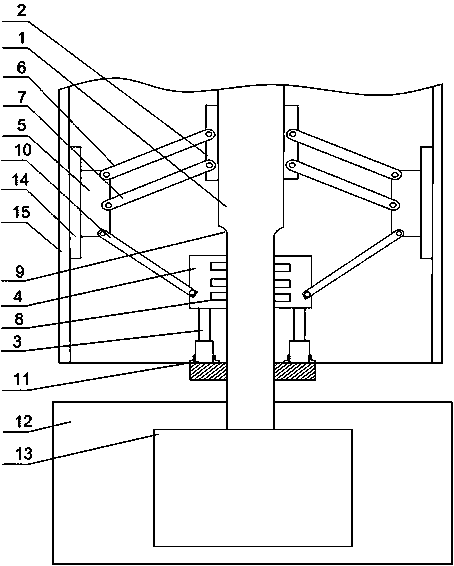

[0022] Such as figure 1 As shown, a pipe fitting 15 bevel processing device of the present invention includes a support frame 12, on which a fixed rod 1 and a drive motor 13 are arranged, and the output end of the drive motor 13 is connected to the bottom of the fixed rod 1, Fixed tube 2 and retaining ring 11 are installed on described fixed rod 1, also comprise cylinder 3, and cylinder 3 is fixed on the retaining ring 11, and the output end of described cylinder 3 is connected with fixed rod 1 through sliding cylinder 4, and sliding cylinder 4. It is arranged between the fixed cylinder 2 and the retaining ring 11. The two ends of the sliding cylinder 4 are hinged to the lower rod 10. The end of the lower rod 10 is hinged to the swing arm 5. The swing arm 5 passes through the upper swing rod 6 and the lower swing rod. 7 is hinged with the fixed cylinder 2, the two ends of the fixed rod 1 are provided with grooves 9, and a plurality of rollers 8 are installed in the sliding cyl...

Embodiment 2

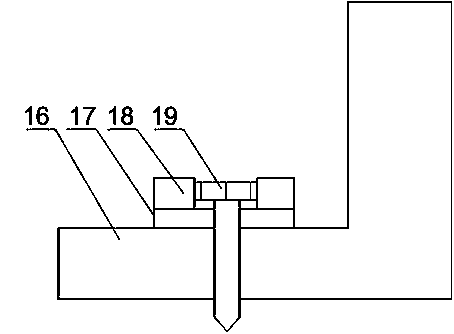

[0025] Such as figure 2 As shown, on the basis of Embodiment 1 in this embodiment, L-shaped baffles 16 are also installed at both ends of the cylinder 3, through holes are opened on the retaining ring 11 and the L-shaped baffle 16, and the retaining ring 11 The L-shaped baffle plate 16 is connected with the L-shaped baffle plate 16 through the through hole through the screw 19, and a washer 17 arranged on the through hole is also included, and an annular protrusion 18 is installed on the washer 17. The retaining ring 11 rotates together with the fixed rod 1, and the cylinder 3 will loosen during the non-stop rotation. The L-shaped baffle 16 clamps both ends of the cylinder 3, and the L-shaped baffle 16 and the retaining ring 11 are connected by screws 19. For connection, the annular protrusion 18 can well protect the screw 19 from external influences and improve the service life of the present invention.

Embodiment 3

[0027] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the end face of the swing arm 5 away from the end of the fixed rod 1 is an arc surface; the arc surface is provided with a backing plate 14, and the arc of the backing plate 14 The surface area is greater than that of the arc surface of the swing arm 5; the roller 8 is a rubber wheel. When clamping the inner wall of the pipe fitting 15, the swing arm 5 is in contact with the inner wall of the pipe fitting 15, and the swing arm 5 on the arc surface can be completely attached to the inner wall of the pipe fitting 15, thereby improving the clamping force of the swing arm 5 on the pipe fitting 15; The backing plate 14 provided on the top can further increase the contact area with the inner wall of the pipe fitting 15 to ensure the stability of clamping.

[0028] Preferably, the rubber wheel can be deformed to a certain extent after the sliding cylinder 4 is subjected to stress, and the reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com