Novel lead storage battery automatic flame welding machine

A lead-acid battery, a new type of technology, applied in battery components, circuits, electrical components, etc., can solve the problems of reduced battery performance and life, large battery contact resistance, energy consumption, etc., to improve battery quality performance, small contact resistance. , Welding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

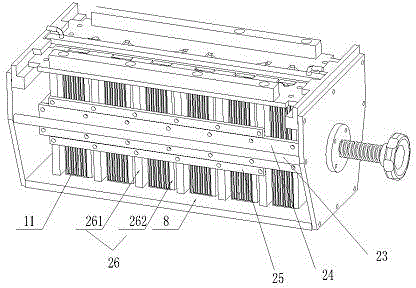

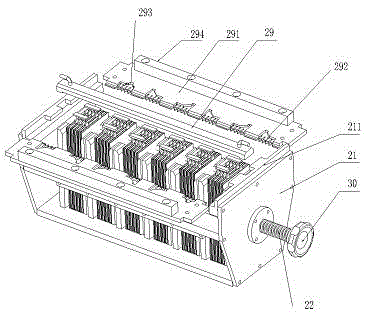

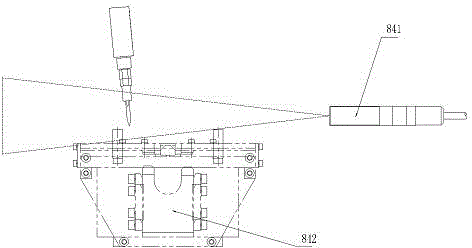

[0025] As shown in the figure, in order to solve the above-mentioned technical problems, a new type of lead storage battery automatic welding machine of the present invention includes a workbench 1, a driving sprocket 10, a driven sprocket 3, a chain 12 and a speed reducer 11. Driven sprocket 10,3 is respectively arranged on described workbench 1 two ends, and main, driven sprocket 10,3 can rotate on workbench 1, and described chain 12 and described main, driven sprocket 10, 3 are meshed, the reducer 11 is arranged under the workbench 1, the rotating shaft of the reducer 11 is fixedly connected with the drive sprocket 10, and the drive sprocket 10 is driven by the reducer 11 to rotate; the chain 12 is fixed A plurality of welding fixtures 2 are provided; one end of the driving sprocket 10 is provided with a sealing cover 5 on the workbench 1, and at least one X-axis single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com