Power magnetic levitation separation and enrichment method and equipment

A magnetic levitation and power technology, applied in the direction of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of magnetic separation process inclusions, non-magnetic material removal, etc., and achieve the effect of reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: see Figure 4 , Figure 5 , a kind of dynamic magnetic levitation sorting and enrichment method, at first a fixed cylindrical barrel 10 is set, inside the barrel 10 around the barrel axis 360 ° in pairs, cross, evenly arranged n pairs of N poles and S poles, relatively The adjacent N poles and S poles form a pair and form a periodically changing alternating dynamic magnetic system, that is, there are 360 / n alternating periods around the axis of the cylinder, and in its single period alternating dynamic magnetic system , the maximum magnetic field strength N of the N pole max 850Gs-4500Gs, the maximum magnetic field strength of the N pole N max Compared with the maximum magnetic field strength S of the S pole max Large 100Gs-400Gs, the alternating dynamic magnetic system rotates around the axis of the cylinder at a certain angular velocity. With the rotation of the alternating dynamic magnetic system, the magnetism in the sorted minerals outside th...

Embodiment 2

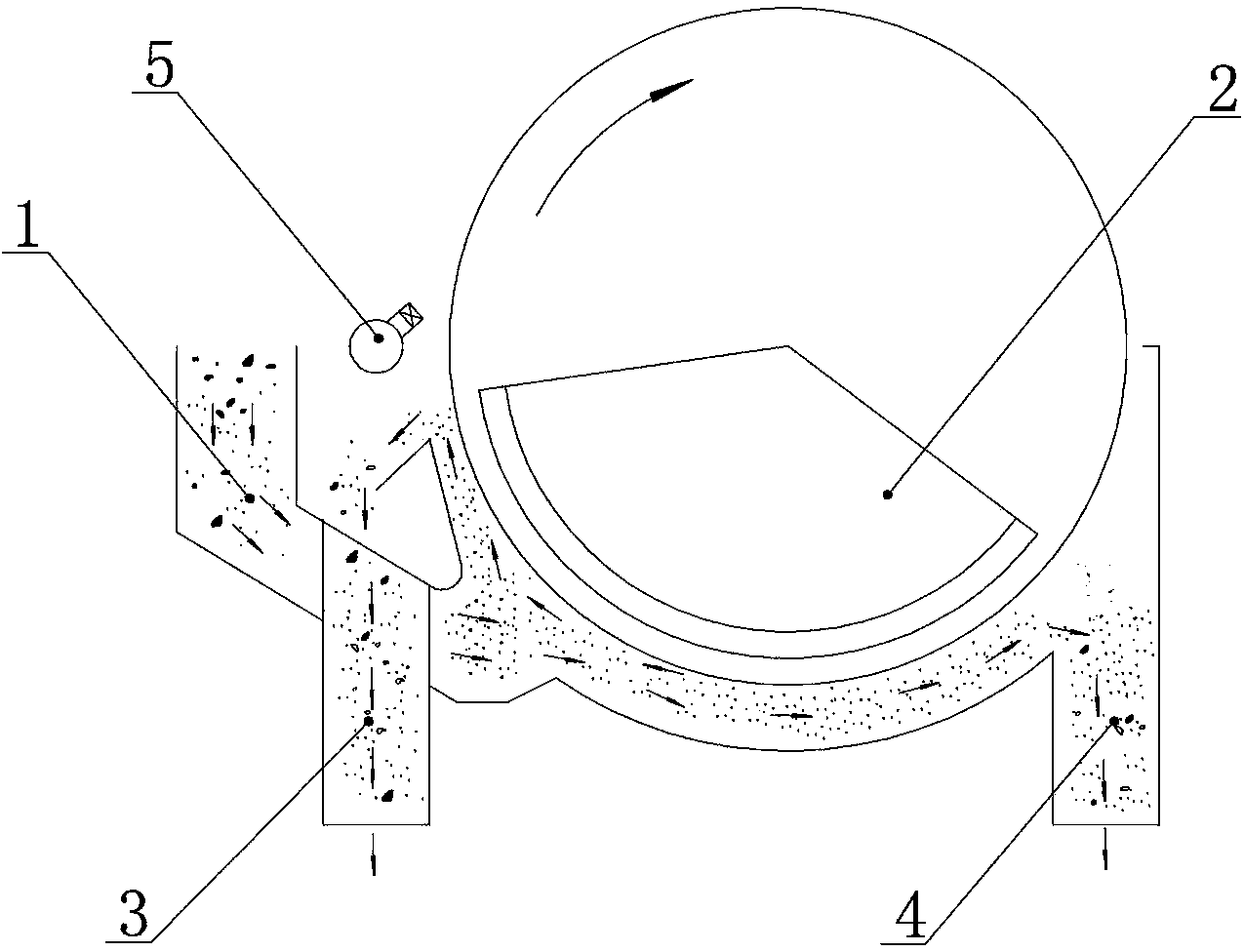

[0035] Embodiment two: see Image 6 , Figure 7, a wet mineral separation and enrichment equipment, including a frame 8, a casing 9 arranged on the frame 8 and a power mechanism, a cylindrical cylinder 10 is fixed inside the casing 9, and the outer surface of the cylinder 10 is in contact with the casing 9 to form a mineral sorting storage bin. The cylinder 10 is provided with a cylindrical magnetic drum 11 that is coaxial with it and can rotate around the axis. The power mechanism drives the magnetic drum 11 to rotate. The axis 360° is provided with an alternating dynamic magnetic system 12 that changes periodically, and the alternating dynamic magnetic system 12 rotates with the magnetic drum 11. Pair, cross, and evenly arrange n pairs of N poles and S poles, adjacent N poles and S poles form a pair of alternating dynamic magnetic systems that change periodically, that is, there are 360 / n alternating magnetic systems around the axis of the cylinder. Change period, in the a...

Embodiment 3

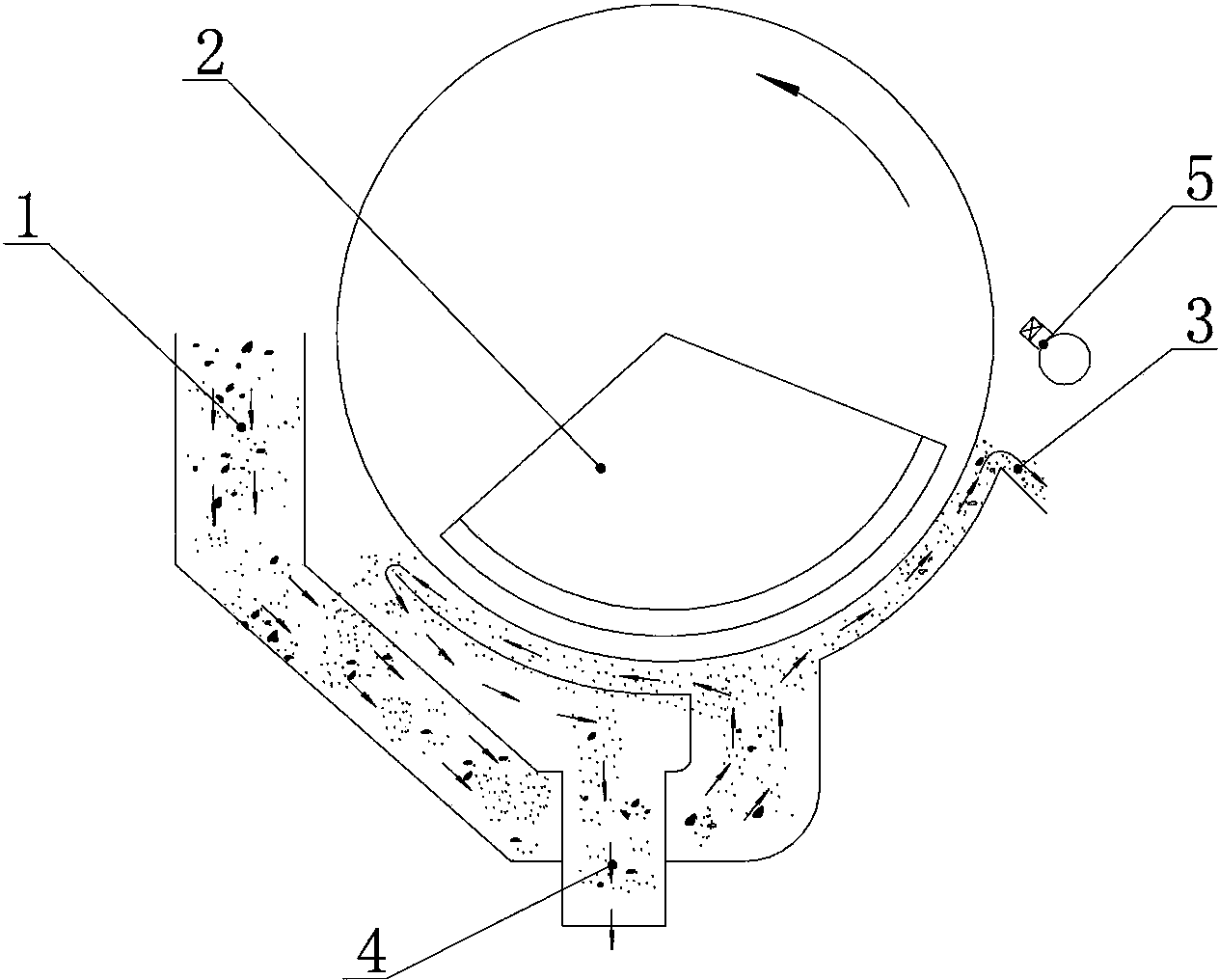

[0036] Embodiment three: see Figure 8 , a dry-type mineral separation and enrichment equipment, including a frame 8 and a casing 9 arranged on the frame 8, a cylindrical cylinder 10 is fixed inside the casing 9, and the outer surface of the cylinder 10 and the casing 9 A mineral sorting storage bin is formed between them, and a cylindrical magnetic drum 11 coaxial with it and rotatable around the axis is arranged in the cylinder body 10. There is an alternating dynamic magnetic system 12 that changes periodically, and the alternating dynamic magnetic system 12 rotates with the magnetic drum 11. The alternating dynamic magnetic system 12 is paired and crossed at 360° around the axis of the cylinder 10 inside the cylinder 10. , Evenly arrange n pairs of N poles and S poles, and a pair of adjacent N poles and S poles form a periodic alternating dynamic magnetic system, that is, there are 360 / n alternating periods around the axis of the cylinder, In the alternating dynamic magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com