Method for preparing single-cell protein powder from biological slurry

A technology of bio-slime and protein powder, which is applied in application, animal feed, animal feed, etc., can solve the problems of only landfill, building materials or incineration, secondary pollution, and low added value, so as to facilitate animal digestion and absorption , The effect of reducing the amount of feed and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

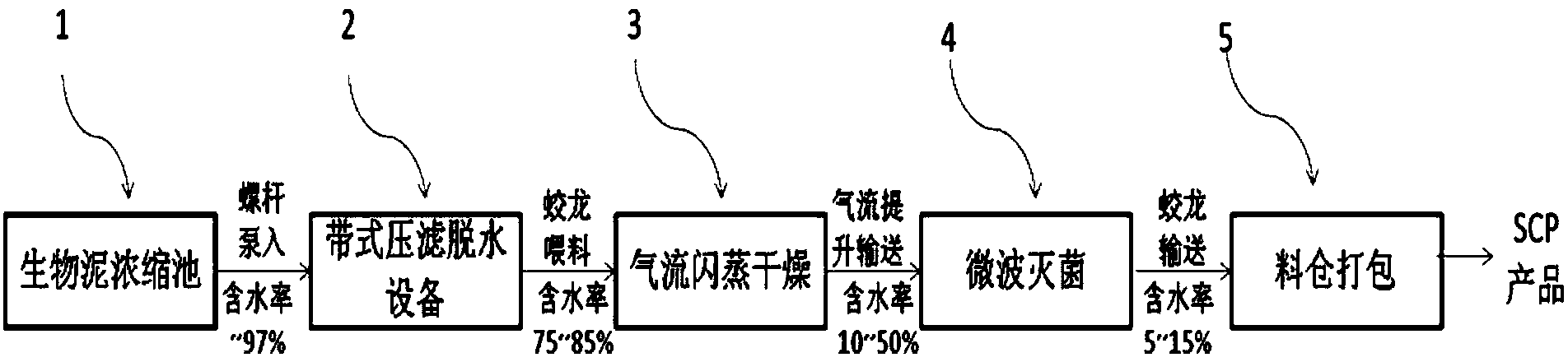

[0027] See attached figure 1 , The preparation method includes the following steps:

[0028] a. Biological mud concentration

[0029] Periodically, the remaining biological mud containing microorganisms in the bioreactor is discharged into the biological mud concentration tank through the pipeline, and the biological mud is self-flowed into the tank from the biological system by its own gravity. The diameter of the pool body in this embodiment: 15 meters, depth: 3.5m, effective volume: 477m 3 The pipeline adopts a diameter of 150mm and a flowmeter diameter of 150mm. The pipeline is equipped with flow rate, velocity and TSS concentration measurement devices. The TSS concentration meter uses an online probe to measure, through the Siemens S-200PLC program module, the flow rate and flow rate are taken 10 times per second. TSS concentration data, accurately calculate the total emissions of TSS. The control flow rate is as follows: TSS concentration in sludge: 2-30g / L, TSS concentratio...

Embodiment 2

[0039] See attached figure 2 , The preparation method includes the following steps:

[0040] a. Biological mud concentration

[0041] Periodically, the remaining biological mud containing microorganisms in the bioreactor is discharged into the biological mud concentration tank through the pipeline, and the biological mud is self-flowed into the tank from the biological system by its own gravity. The diameter of the pool body in this embodiment: 15 meters, depth: 3.5 meters, effective volume: 477 meters 3 The pipeline adopts a diameter of 150mm and a flowmeter diameter of 150mm. A flow, velocity and TSS concentration metering device is installed on the pipeline. The TSS concentration meter uses an online probe to measure, through the Siemens S-200PLC program module, the flow rate and flow rate are taken 10 times per second. TSS concentration data, accurately calculate the total emissions of TSS. The control flow is as follows: TSS concentration in sludge: 2-30g / L, TSS concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com