Spectacles leg manufacturing method

A production method and technology of glasses legs, which are applied in the directions of glasses/goggles, optics, instruments, etc., can solve the problems of easy rust, skin and ear bone damage, and hard glasses legs, so as to achieve beautiful and comfortable wearing and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

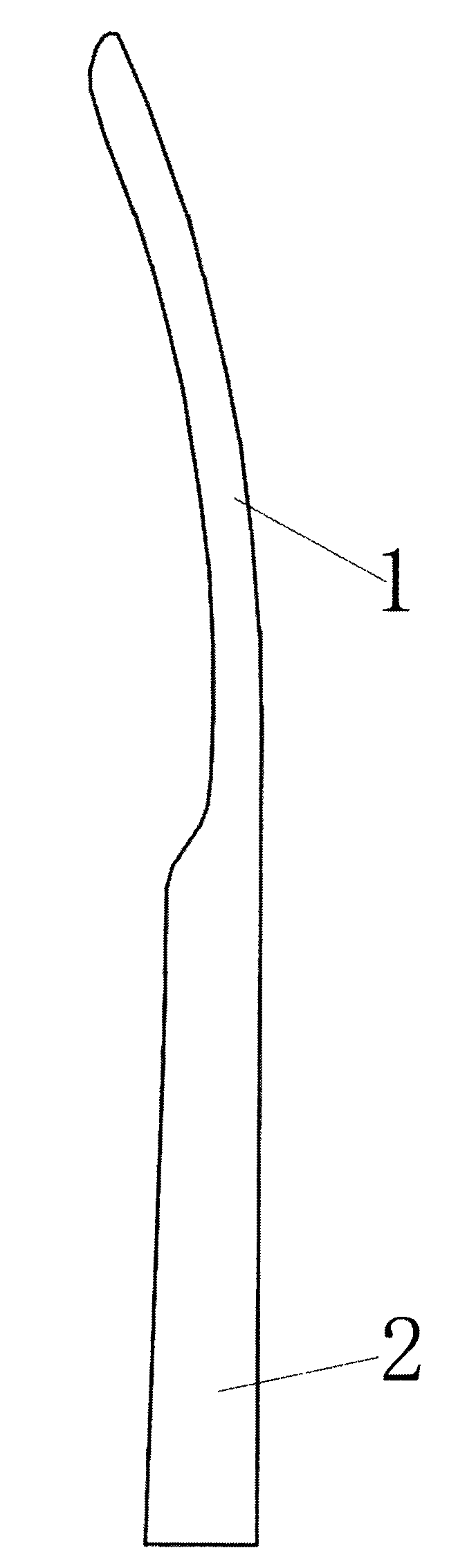

[0012] As shown in the attached figure, it is a method of making glasses legs. The body of the glasses body is divided into a bending part 1 and a supporting part 2. The bending part 1 and the supporting part 2 are integrally pressed and formed. The inside of the glasses body is two thirds of a silicone layer. The outside is one-third of the nylon adhesive layer, the silicone layer and the nylon adhesive layer are composited, and are glued, pressed, and polished at 200 degrees by environmentally friendly glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com