A flange head copper alloy four-leaf even rib variable channel horizontal valve

A technology of variable flow channel and copper alloy, which is applied in the direction of valve lift, valve detail, control valve, etc., and can solve the problems of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

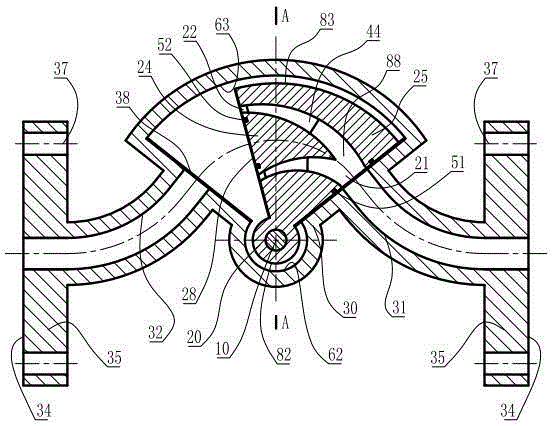

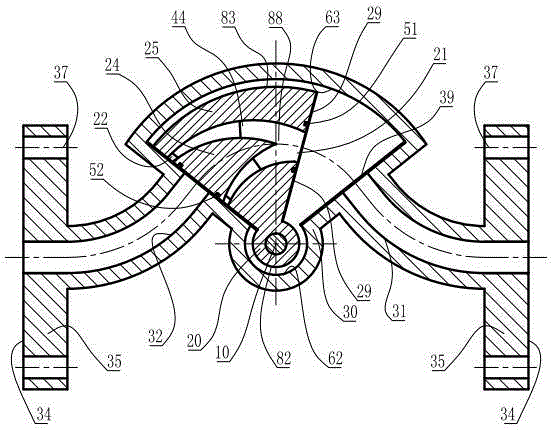

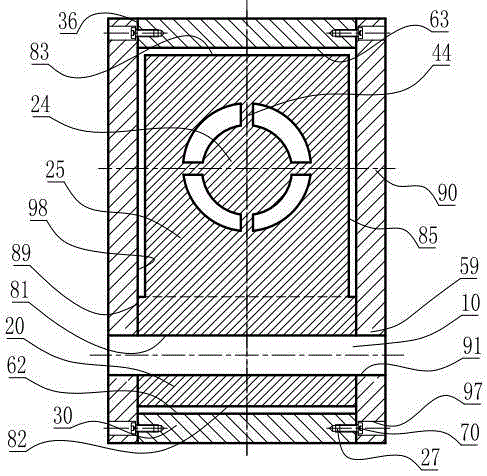

[0030] Figure l, figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Among them, a flange-head copper alloy four-leaf even rib variable flow channel horizontal valve, including a cylindrical shaft 10, a swing valve core 20, a flange joint valve body 30, a fastening screw 70 and an outer end cover 90, as an improvement: The outlet elbow 31 on the flange joint valve body 30 and the outer end of the inlet elbow 32 have a connecting flange 35, and the outer end of the connecting flange 35 is a flange sealing plane 34, and there are 4 flanges on the flange sealing plane 34. to 8 bolt through holes 37; the inner end of the inlet elbow 32 is connected to the valve body inlet plane hard layer 38 of the flange joint valve body 30, and the inner end of the outlet elbow 31 is connected to the The valve body outlet plane hard layer 39 of the flange joint valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com