Welding chromium alloy atoll seawater separating and desalting equipment

A chrome alloy and fresh water technology, which is applied in the field of welding chrome alloy island reef sea water separation fresh water equipment, achieves considerable indirect benefits, avoids accidental failures, and is agile in action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

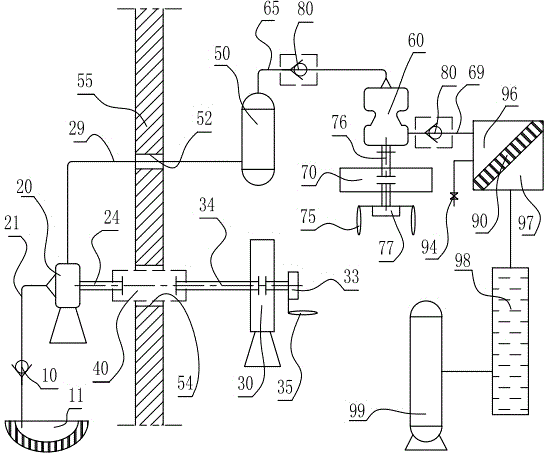

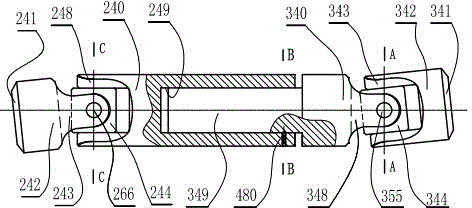

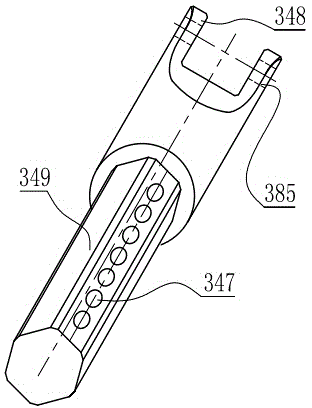

[0036] A welded chrome alloy island and reef seawater separation freshwater equipment, the single hand crank 33 located in the room drives the primary output shaft 34 of the primary speed-up box 30 to rotate between 700 and 720 revolutions per minute, the primary output shaft 34 and the chrome alloy The coupling input welding groove 341 of the welding head hexagonal telescopic coupling 40 is welded and fixed, and the hexagonal telescopic coupling 40 of the chrome alloy welding head passes through the transmission pipe sealing hole 54 of the partition wall 55 from the inside to the outside. The coupling output welding groove 241 of the alloy welding head hexagonal telescopic coupling 40 is welded and fixed to the low-pressure pump input shaft 24 of the low-pressure centrifugal pump 20, and the lifting inlet pipe 21 of the low-pressure c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com