Local excavation pre-supporting raise boring technology

A local excavation and pre-support technology, applied in drilling equipment, wellbore lining, shaft equipment, etc., can solve the problems of instability, weak bedrock, sensitive structures such as uneven settlement, and reduce operating time and labor. The effect of strength and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

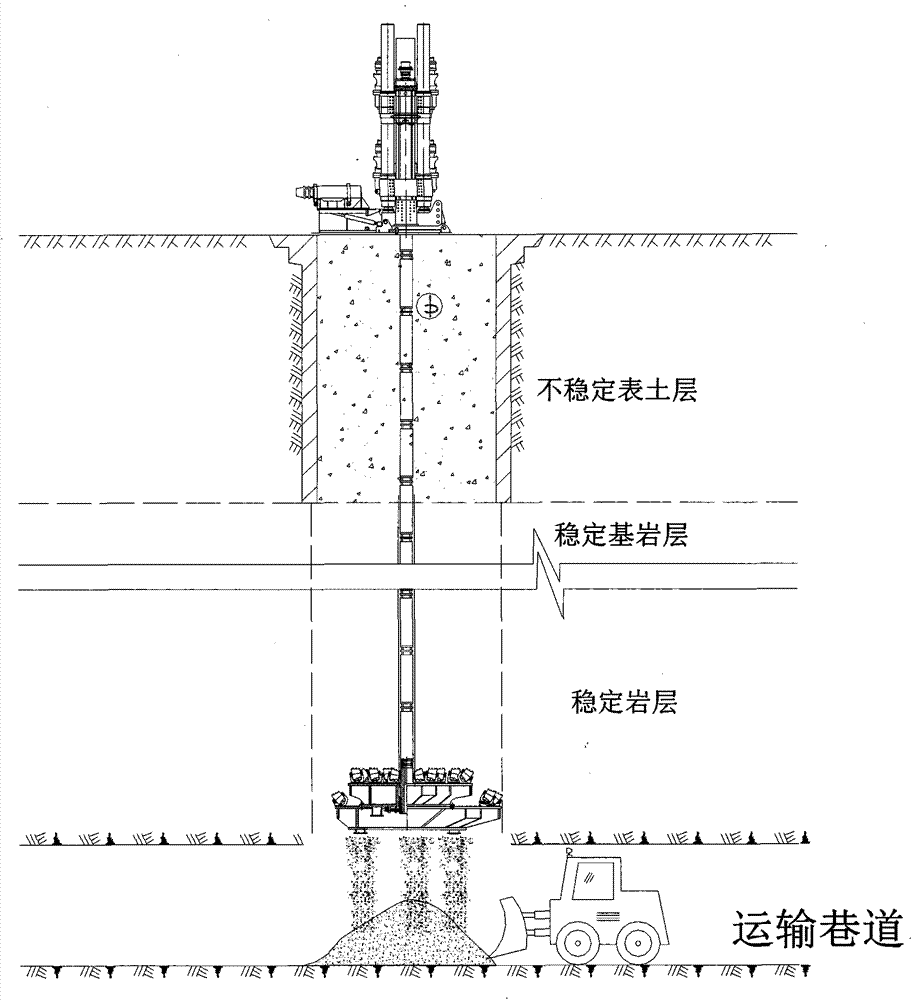

[0029] Such as Figure 1 to Figure 3 As shown, a kind of local excavation pre-supporting raising shaft drilling technology of the present embodiment is carried out auxiliary return air shaft raising shaft construction test in Wangtaipu Coal Mine, Jincheng City, Shanxi Province, including the following steps:

[0030] (a) Geological data analysis

[0031] Analyze the geological data provided by the geology and design departments, drill engineering inspection holes near the wellbore before construction, and collect the geological and hydrological conditions of the nearby wellbore or other basic engineering and water wells. When the thickness of the formation is within 30m, the lower rock is stable, and the water consumption does not exceed 20m 2 / h situation].

[0032] (b) Ground excavation

[0033] Use manual excavation or small excavator to excavate, put the gangue into the bucket, hoist it to the ground for stacking, and transport it out of the site; use shotcrete as the p...

Embodiment 2

[0049] Such as Figure 1 to Figure 3 As shown, a kind of local excavation pre-supporting raising shaft drilling technology in this embodiment is carried out in the Lanhua Baoxin Coal Mine in Guxian County, Shanxi Province to carry out the auxiliary return air shaft raising shaft construction test, including the following steps:

[0050] (a) Geological data analysis

[0051] Analyze the geological data provided by the geology and design department, according to the geological histogram described by the engineering inspection hole near the shaft, drill the engineering inspection hole near the shaft before construction, and collect the geological and hydrological conditions of the adjacent shaft or other basic engineering and water wells, When the thickness of the soil or unstable stratum is within 30m, the underlying rock is stable, and the water consumption does not exceed 20m 2 / h.

[0052] (b) Ground excavation

[0053] Use manual excavation or small excavator excavation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com