Double-component high heat-conducting pouring sealant with excellent mechanical properties and preparation method thereof

A potting glue, two-component technology, applied in the direction of chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of reduced fluidity, and achieve the effect of improving impact resistance, high thermal conductivity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

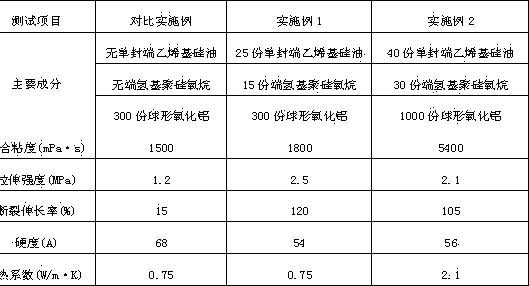

Examples

preparation example Construction

[0033] The preparation method of component A is: add 145 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C and 1 part of 2000ppm Pt complex catalyst into a planetary stirring tank, and when the vacuum degree is greater than 0.095MPa, control Stir for 20 minutes at a temperature of 50-60°C, mix evenly to remove air bubbles; add 300 parts of mixed spherical alumina with an average particle size of 30 μm and 7 μm in a ratio of 1:1 to the stirring tank, and in a vacuum greater than 0.095 MPa Stir for 60min under the condition, and finally component A can be obtained.

[0034] The preparation method of component B is: 135 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C, 10 parts of hydrogen-containing polysiloxane with a hydrogen content of 0.25%, 1,3,5,7-tetra Add 0.1 part of vinyl-1,3,5,7-tetramethylcyclotetrasiloxane inhibitor into the planetary stirring tank, stir for 20min under the condition of vacuum degree greater than 0.095MPa, temperature c...

Embodiment 1

[0036] The preparation method of component A is: 120 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C, 25 parts of mono-capped vinyl silicone oil with a viscosity of 1000mpa·s at 25°C, and 2000ppm of Pt complex Add 1 part of the catalyst to the planetary stirring tank, stir for 20 minutes under the conditions of vacuum degree greater than 0.095MPa, temperature control 50-60°C, mix evenly and debubble; mix the average particle size of 30μm and 7μm in a ratio of 1:1 Add 300 parts of spherical alumina into the stirred tank, and stir for 60 minutes under the condition that the vacuum degree is greater than 0.095 MPa, and finally component A can be obtained.

[0037]The preparation method of component B is: 100 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C, 30 parts of hydrogen-containing polysiloxane with a hydrogen content of 0.25%, and a terminal hydrogen group with a hydrogen content of 0.18% 15 parts of polysiloxane and 0.1 part of 1,3,5,7-te...

Embodiment 2

[0039] The preparation method of component A is: 105 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C, 40 parts of mono-capped vinyl silicone oil with a viscosity of 1000mpa·s at 25°C, and 2000ppm of Pt complex Add 1 part of the catalyst to the planetary stirring tank, stir for 20 minutes under the conditions of vacuum degree greater than 0.095MPa, temperature control 50-60°C, mix evenly and debubble; mix the average particle size of 30μm and 7μm in a ratio of 1:1 Add 1,000 parts of spherical alumina into the stirred tank, stir for 90 minutes under the condition of a vacuum greater than 0.095 MPa, and finally obtain component A.

[0040] The preparation method of component B is: 100 parts of polyorganosiloxane with a viscosity of 200mpa·s at 25°C, 15 parts of hydrogen-containing polysiloxane with a hydrogen content of 0.25%, and a terminal hydrogen group with a hydrogen content of 0.18% 30 parts of polysiloxane and 0.1 part of 1,3,5,7-tetravinyl-1,3,5,7-tetrame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com