Method for treating waste CRT (cathode ray tube) and preparing glass ceramics by using slag

A glass-ceramic and slag technology, which is applied in the field of comprehensive utilization of resources, can solve the problem of little research on the consolidation effect of heavy metal ions, and achieve the effects of saving energy consumption for melting, reducing costs, and saving energy and emission reduction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

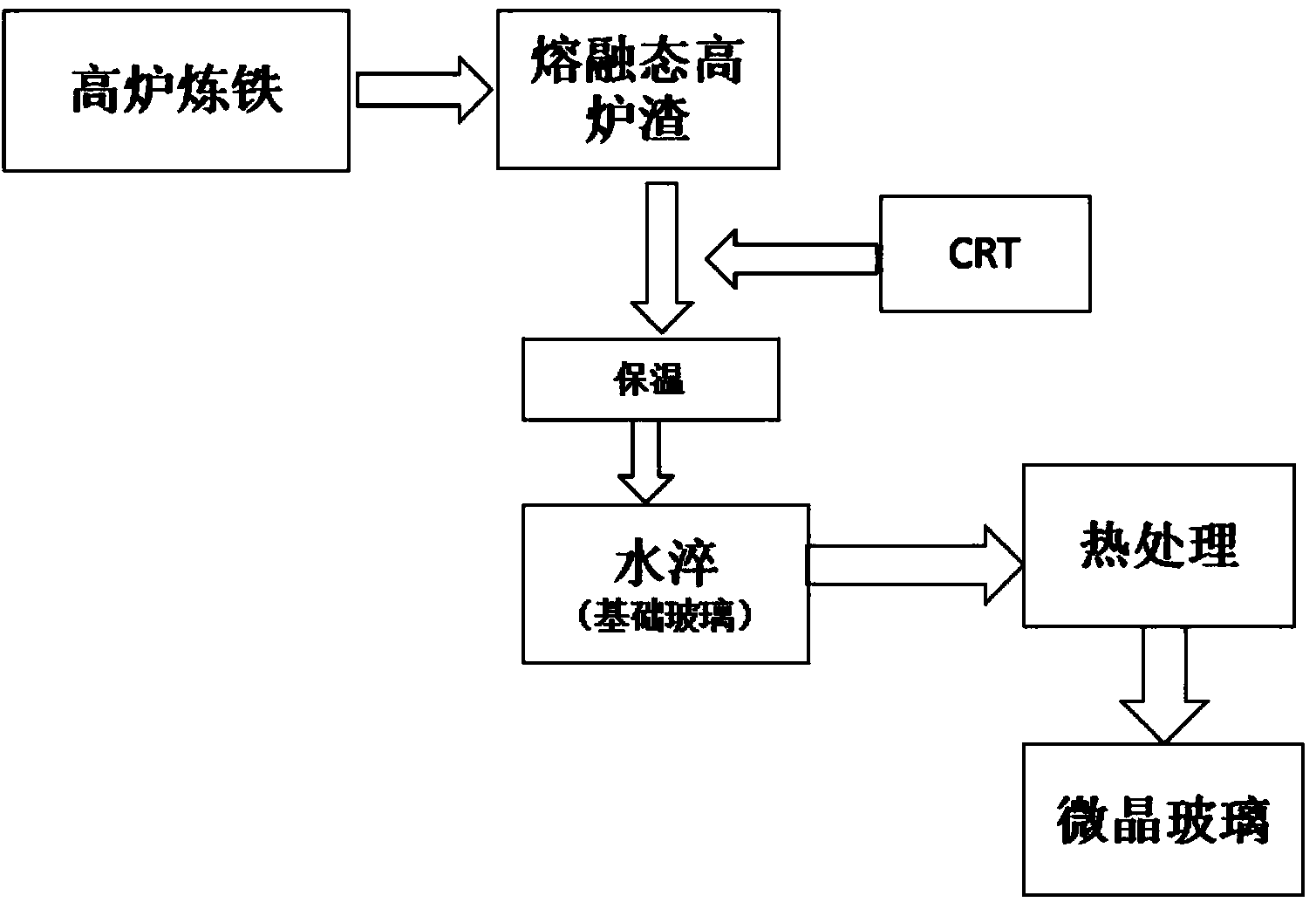

[0021] Such as figure 1 As shown, the embodiment of the present invention: use molten slag to process waste CRT and adopt sintering method to prepare glass-ceramic, its specific process is as follows: waste CRT is carried out grinding, pass 200 mesh sieves, then according to the ratio that accounts for 25% of total raw material It is added to the blast furnace slag discharged from a steel plant, and after the slag is mixed, it is quickly water-quenched at a temperature of 1450°C. Grinding after drying, and passing through a 200-mesh sieve to obtain basic glass frit.

[0022] The powdery basic glass frit is pressed into blocks according to the required volume at a pressure of 10MPa, and put into a heating furnace for processing. The heat treatment system is: nucleation temperature 800°C, nucleation heating rate 10°C / min, nucleation holding time 1h, the crystallization temperature is 850°C, the crystallization heating rate is 4°C / min, the crystallization holding time is 1h, the...

Embodiment 2

[0024] Such as figure 1 As shown, the embodiment of the present invention: use molten slag to process waste CRT and adopt sintering method to prepare glass-ceramic, its specific process is as follows: waste CRT is carried out grinding, pass 200 mesh sieves, then according to the ratio that accounts for 35% of total raw material It is added to the blast furnace slag discharged from a steel plant, and after the slag is mixed, it is quickly water-quenched at a temperature of 1500°C. Grinding after drying, and passing through a 200-mesh sieve to obtain basic glass frit.

[0025] The powdery basic glass frit is pressed into blocks according to the required volume at a pressure of 10MPa, and put into a heating furnace for processing. The heat treatment system is: nucleation temperature 780°C, nucleation heating rate 10°C / min, nucleation holding time 1h, the crystallization temperature is 870°C, the crystallization heating rate is 4°C / min, the crystallization holding time is 1h, the...

Embodiment 3

[0027] Such as figure 1 As shown, the embodiment of the present invention: use molten slag to process waste CRT and adopt sintering method to prepare glass-ceramic, its specific process is as follows: waste CRT is carried out grinding, pass 200 mesh sieves, then according to the ratio that accounts for 45% of total raw material It is added to the blast furnace slag discharged from a steel plant, and after the slag is mixed, it is quickly water-quenched at a temperature of 1400°C. Grinding after drying, and passing through a 200-mesh sieve to obtain basic glass frit.

[0028] The powdery basic glass frit is pressed into blocks according to the required volume at a pressure of 10MPa, and put into a heating furnace for processing. The heat treatment system is: nucleation temperature 800°C, nucleation heating rate 10°C / min, nucleation holding time 1h, the crystallization temperature is 850°C, the crystallization heating rate is 4°C / min, the crystallization holding time is 1h, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com