Carbon fiber tube

A technology of carbon fiber tube and carbon fiber, which is applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of general reinforcement effect and single structure, and achieve the effect of good reinforcement effect, increased strength and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

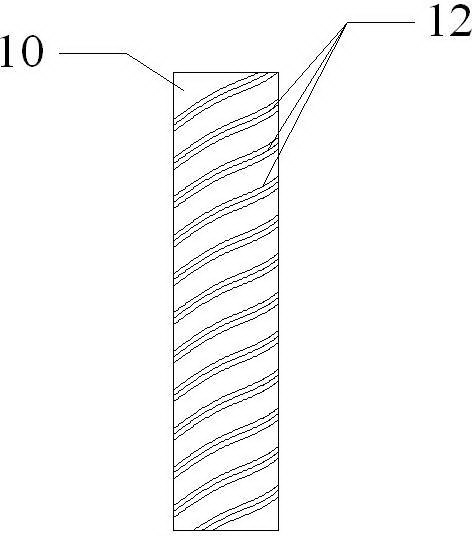

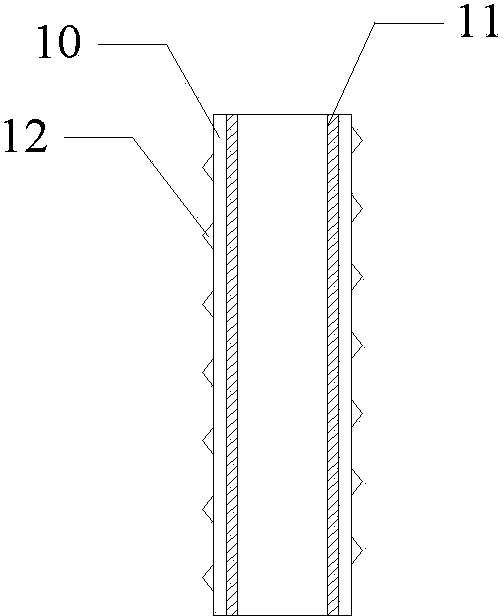

[0017] Such as figure 1 , figure 2 The shown carbon fiber tube includes a cylindrical tube body 10, the tube body 10 is a carbon fiber tube body, the inner side of the tube body 10 is provided with a metal inner wall 11, and the outer side of the tube body 10 is provided with a plurality of helical reinforcing ribs 12, many The helical reinforcing ribs are parallel to each other, and each helical reinforcing rib 12 is evenly distributed, and the distance between each helical reinforcing rib 12 is equal to 1.5 to 2 times the helical reinforcing rib 12 and the pipe body. 10 Width at contact. The metal inner wall 11 adopts an aluminum tube to closely fit the carbon fiber tube body. The aluminum is lightweight, and the carbon fiber tubes on the outside add strength.

[0018] The helix angle of the helical reinforcing rib 12 is 45°-60°. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com