Maraging steel

A technology of maraging steel and Vickers hardness, applied in V-shaped belts, coatings, belts/chains/gears, etc., can solve problems such as insufficient strength, and achieve excellent mechanical properties, high fatigue strength properties, high Effect of Strength and Fatigue Strength Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

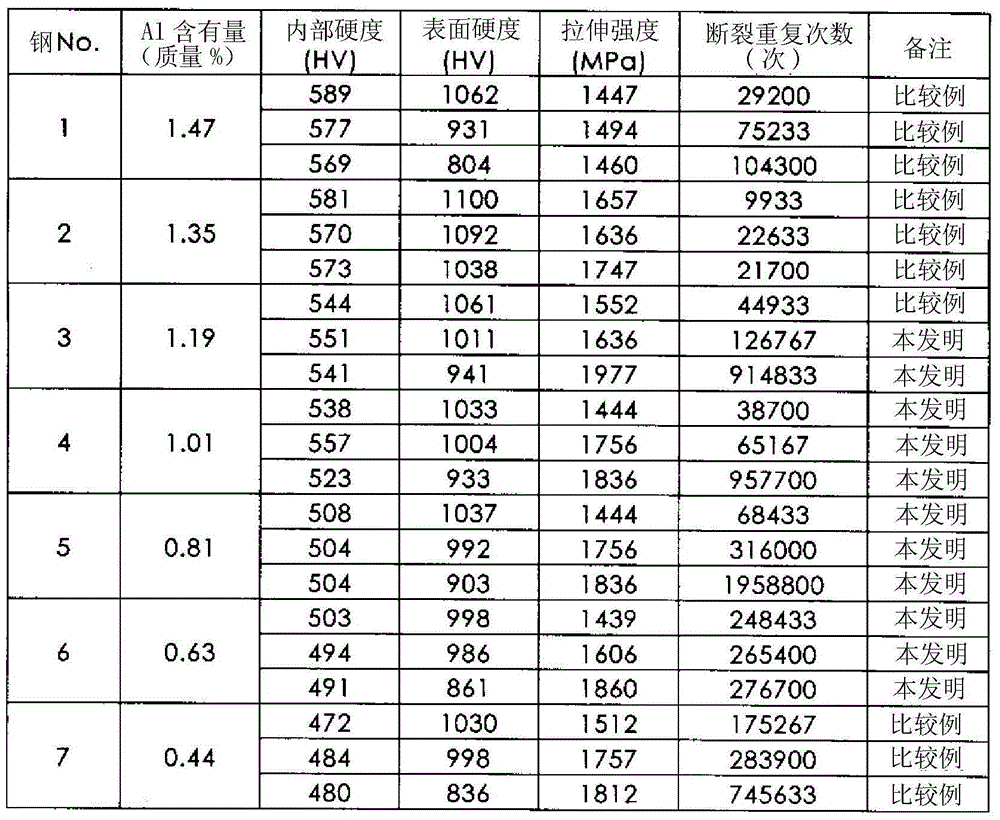

[0086] The present invention will be described in more detail using the following examples.

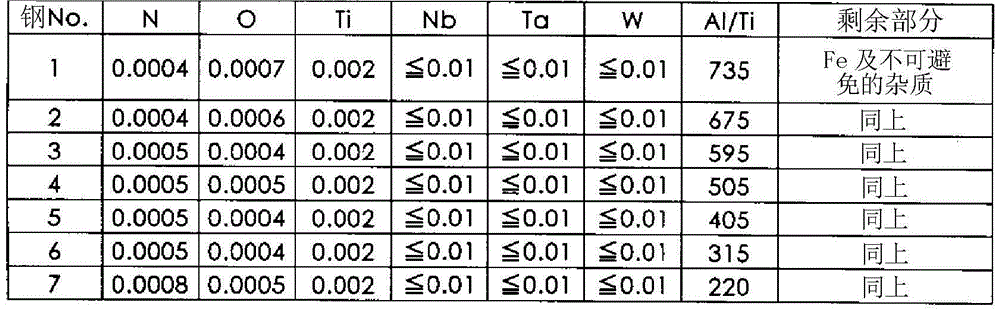

[0087] Seven kinds of steel ingots weighing 10 kg were produced using a vacuum induction melting furnace. In order to more reliably prevent contamination of Ti, Nb, Ta, and W, elements that should be restricted, high-purity alloy raw materials are used as the alloy raw materials to be added.

[0088] Homogenizing annealing was performed on the produced steel ingot, and then hot forging was performed. Then, it is made into maraging steel with a thickness of about 0.2mm by hot rolling and cold rolling, which is used as the maraging steel for the metal endless belt of CVT.

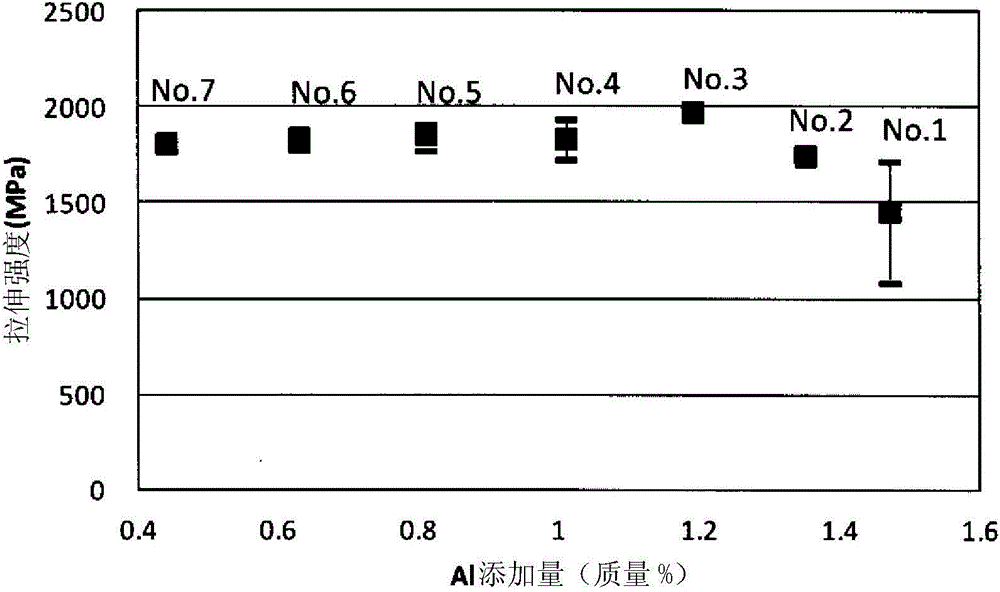

[0089] Table 1 shows the chemical composition and Al / Ti ratio of the obtained maraging steel. The C content in all the maraging steels was adjusted to a range of 0.008% or less, thereby preventing a decrease in weldability. In addition, the Al content of the maraging steels No. 1, No. 2, and No. 7 exceeded the ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com