Flexible battery pack and preparation method thereof

A flexible battery pack and a manufacturing method technology, which are applied in the manufacture of secondary batteries, battery pack components, and isolation of batteries from their environment, can solve the problems of decreased bonding strength, poor reliability, and great difficulty, and achieve flexibility High strength and fatigue resistance, good for flexibility, and the effect of improving bending ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

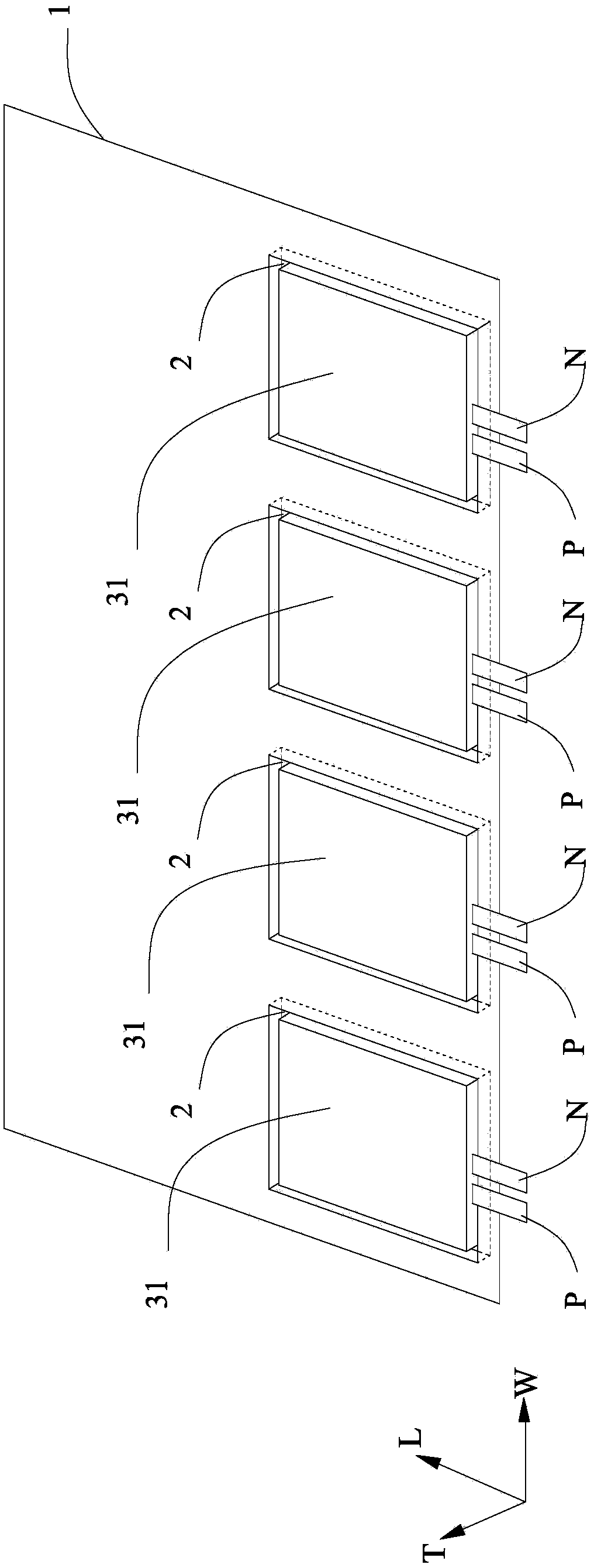

[0048] Embodiment 1 (with reference to Figure 1 to Figure 7 setting method)

[0049] Set six punching pits 2 on the aluminum-plastic film 1, the length of the punching pits 2 is 2 mm longer than the length of the battery cell 31, the width of the punching pits 2 is 1.5 mm larger than the width of the battery cell 31, and the thickness of the punching pits 2 is larger than that of the battery cell 31. The thickness of 31 is 0.4 mm smaller; the distance between two adjacent punching pits 2 is 3 cm. Then, the battery cells 31 with a water content of 300 ppm are placed in the flushing pit 2 at intervals. Fold the other side of the aluminum-plastic film 1 in half to this side, leaving a 4cm length of the air bag G, and perform side sealing on each punching pit 2, the side sealing temperature is 195°C, the side sealing time is 20s, and the side sealing The pressure is 1MPa; top sealing is performed after injecting a liquid electrolyte containing lithium salt LiPF6 and solvent eth...

Embodiment 2

[0050] Embodiment 2 (with reference to Figure 1 to Figure 7 setting method)

[0051] Set six punching pits 2 on the aluminum-plastic film 1, the length of the punching pits 2 is 3mm longer than the length of the battery cell 31, the width of the punching pits 2 is 2.5mm larger than the width of the battery cell 31, and the thickness of the punching pits 2 is larger than that of the battery cell 31. The thickness of 31 is 0.5mm smaller; the distance between two adjacent punching pits 2 is 3.5cm. Then, the wound electric cores 31 with a water content of 250 ppm are placed into the flushing pit 2 at intervals. Fold the other side of the aluminum-plastic film 1 in half to this side, leaving a 5cm length of the air bag G, and perform side sealing on each punching pit 2, the side sealing temperature is 165°C, the side sealing time is 2s, and the side sealing The pressure is 0.2MPa; top sealing is performed after injecting a solid electrolyte containing lithium salt LiPF6, the top...

Embodiment 3

[0052] Embodiment 3 (with reference to Figure 1 to Figure 7 setting method)

[0053] Six punching pits 2 are set on the aluminum-plastic film 1, the length of the punching pits 2 is 2.5 mm longer than the length of the battery cell 31, the width of the punching pits 2 is 2 mm larger than the width of the battery cell 31, and the thickness of the punching pits 2 is larger than that of the battery core 31. The thickness of 31 is 0.45mm smaller; the distance between two adjacent punching pits 2 is 4cm. Then, the laminated battery cells 31 with a water content of 200 ppm are placed in the flushing pit 2 at intervals. Fold the other side of the aluminum-plastic film 1 to this side, leaving a length of air bag G of 4.5cm, and perform side sealing on each punching pit 2, the side sealing temperature is 180°C, the side sealing time is 10s, and the side sealing time is 10s. The sealing pressure is 0.6MPa; the top sealing is performed after injecting the gel electrolyte containing li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com