Automatic gas extraction drilling basic parameter monitoring device

A basic parameter, automatic monitoring technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

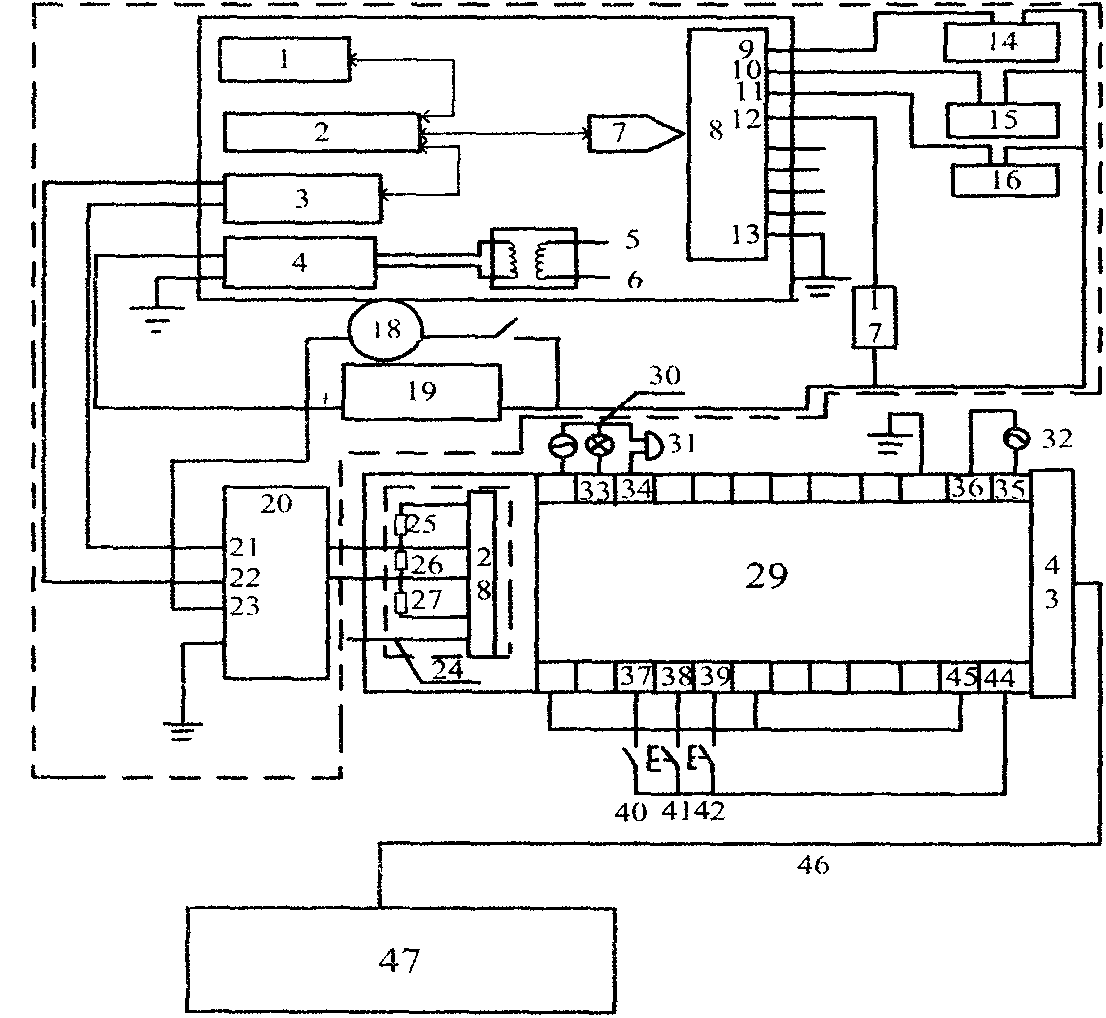

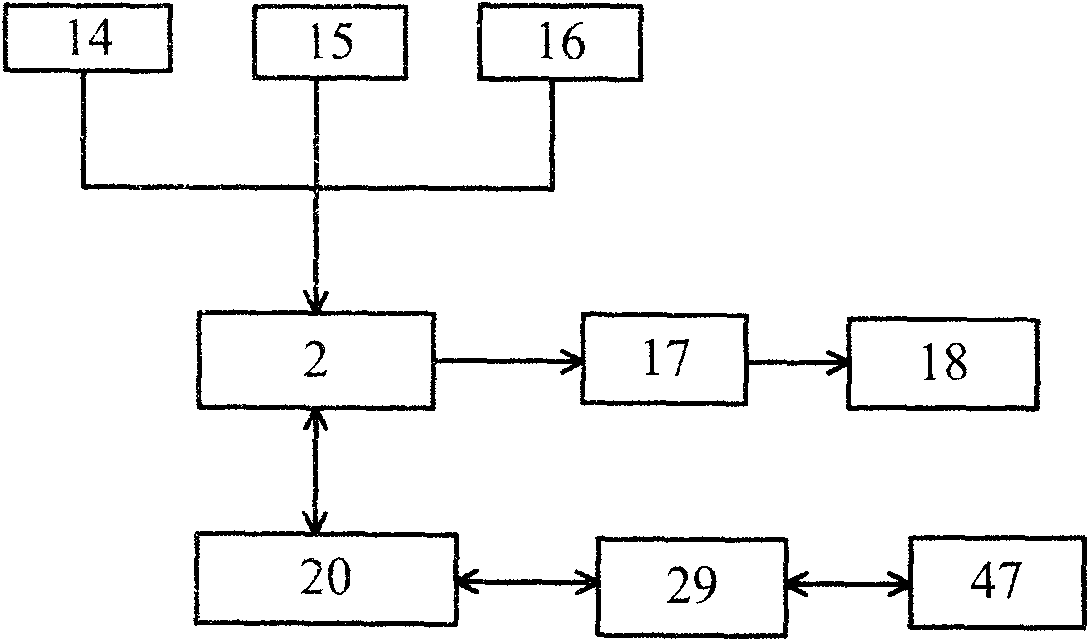

[0009] exist figure 1 , the device is divided into two parts, the black dotted box marks the downhole part, and the rest are the uphole part. When the device started to work, the PLCCPU221 (29) was powered by a 220V AC power supply (32), wherein the neutral wire end of the power supply was connected to the N (36) live wire end and pressed to the L (35). Press the start button (42), and at the same time supply power to the 24V switching power supply (19), at this moment the gas concentration detector (14), the gas pressure detector (15), and the flow detector (16) start working, and the analog quantity is detected The data are sent to three ports IN1 (9), IN2 (10), and IN3 (11), integrated by a multiplexer (8), and the analog data is converted into digital data by an analog-to-digital converter (7). At this point, the embedded controller (2) will organize the received data. When the data is too large, the EEPROM (1) will perform a transfer cache, and the data integrated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com