Multi-actuator cylinder cooperative control device and control method

A technology of cooperative control and actuating cylinders, which is applied in the directions of comprehensive factory control, comprehensive factory control, and electrical program control, etc., can solve problems such as asymmetrical movement positive and negative distances, difficult hardware limit calibration, and easy failures, etc., to prevent The effects of burning out the circuit, reducing the installation size, and avoiding attitude errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

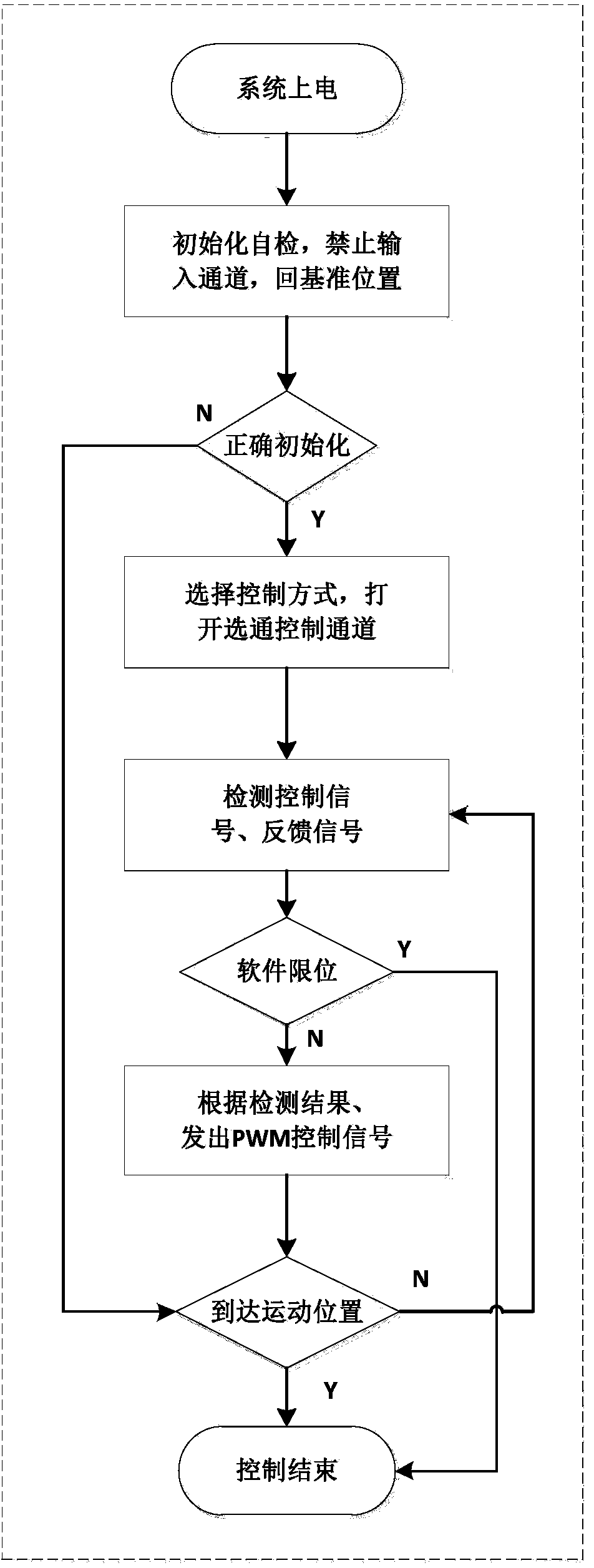

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

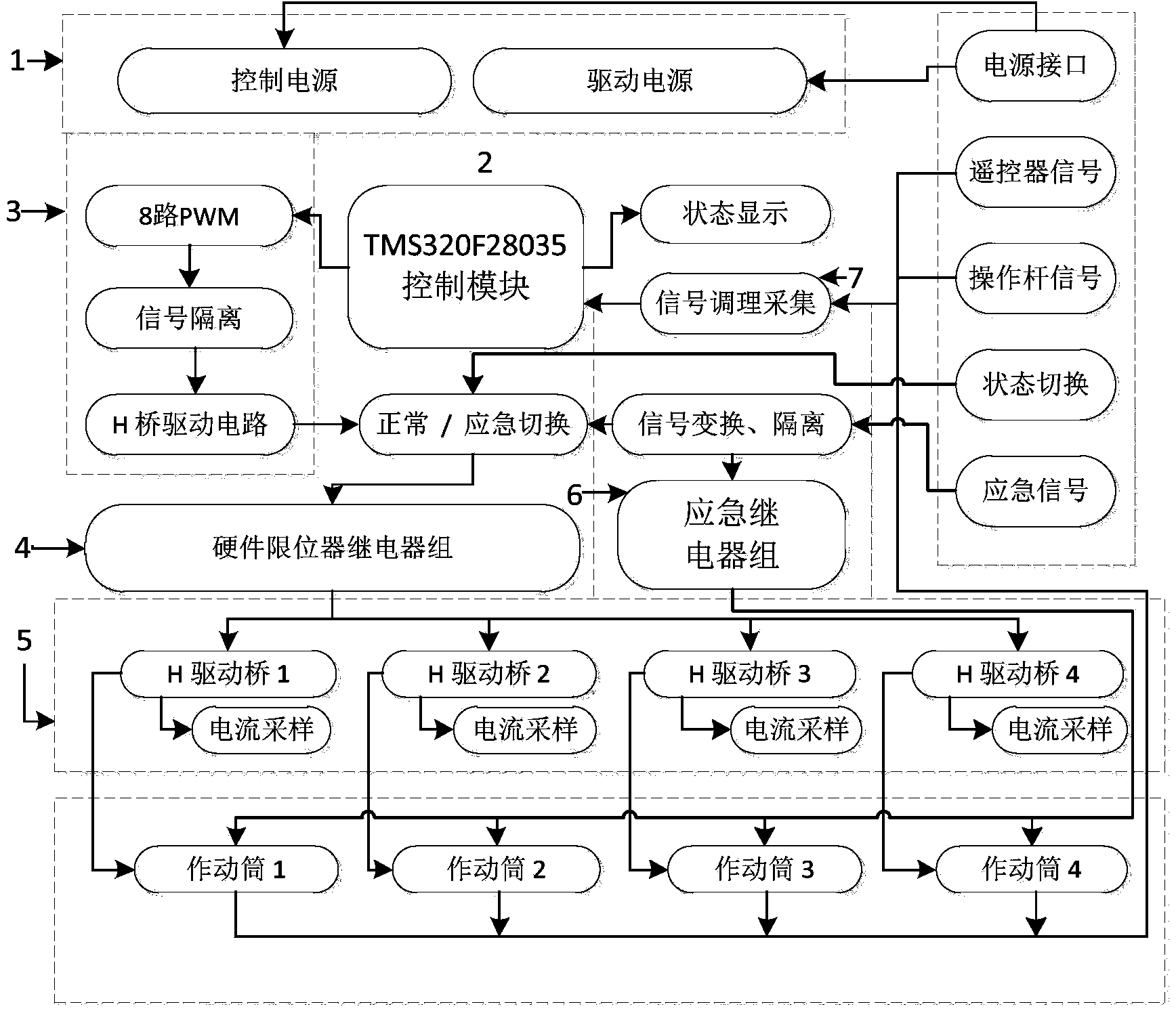

[0039] The invention provides a multi-actuating cylinder cooperative control device, and the improvement of the invention includes the improvement of the control circuit of the actuating cylinder and the improvement of the multi-actuating cylinder cooperative control method.

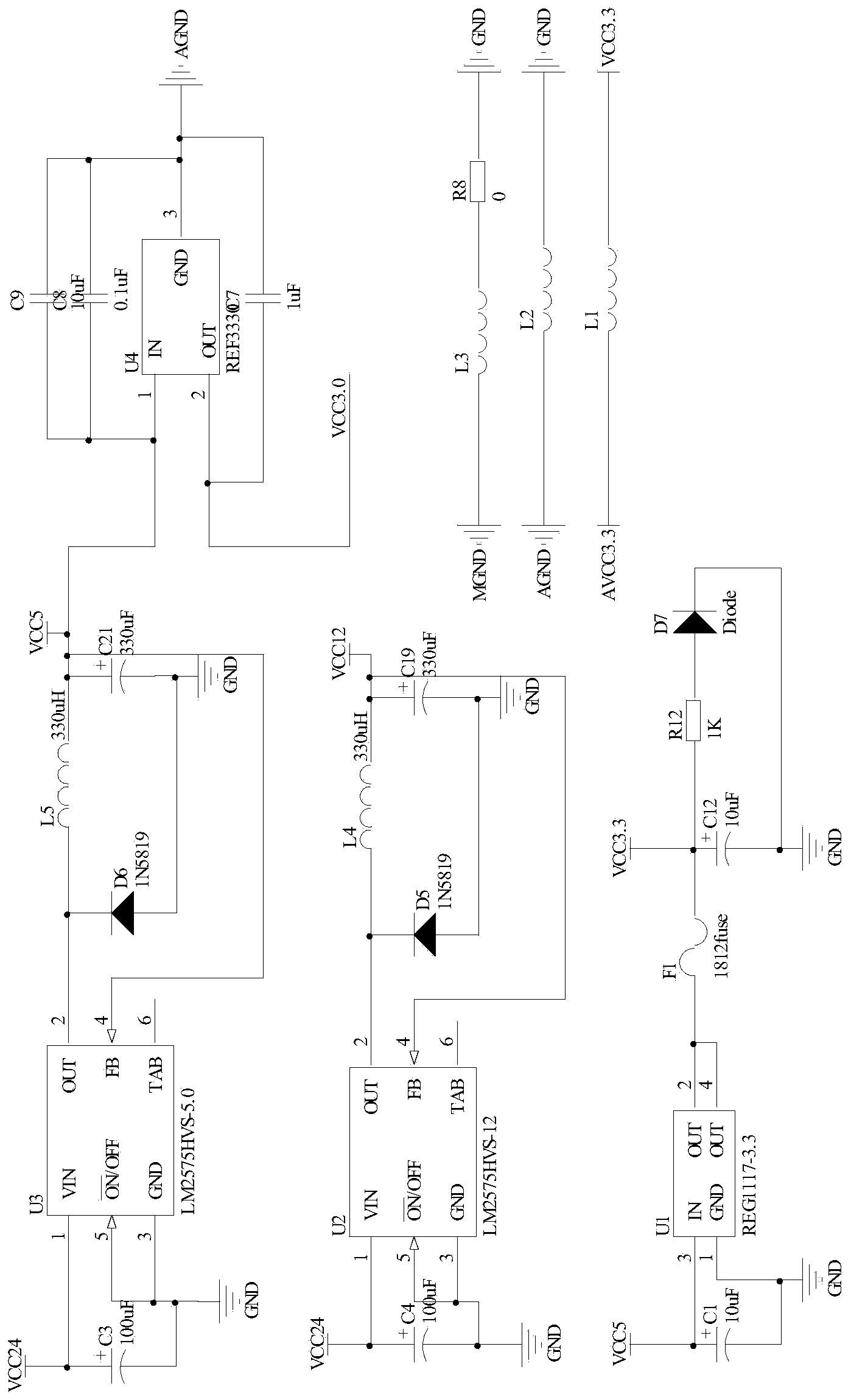

[0040] The control circuit includes: power supply module 1; TMS320F28035 processor module 2; control signal isolation and amplification module 3; hardware limit relay group 4; H bridge drive circuit 5; emergency module 6; signal conditioning sampling circuit 7, in which:

[0041] The power supply module 1 provides energy for each part of the system, and the voltage required by each module of the device of the present invention is shown in Table 1 below. It is divided into driving power and control power: the driving voltage of the actuator is 24V, which is directly input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com