Method and device for testing thermal performance of LED radiator

A technology of LED radiator and testing device, applied in the direction of thermal conductivity of materials, etc., can solve the problems of complex fixing device, inability to realize the thermal performance test of radiator, affecting the natural convection of radiator, etc., achieving wide application range, simple structure, clamping Tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

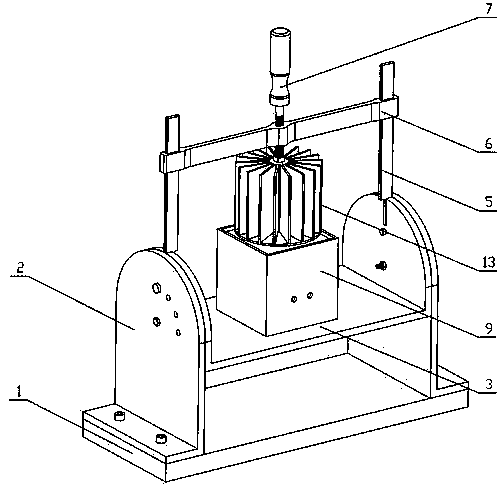

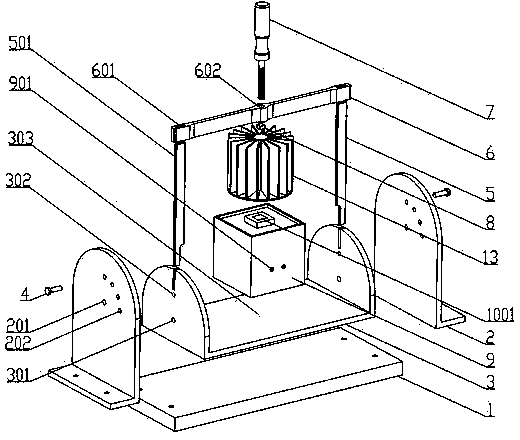

[0037] Such as figure 1 , 3 shown.

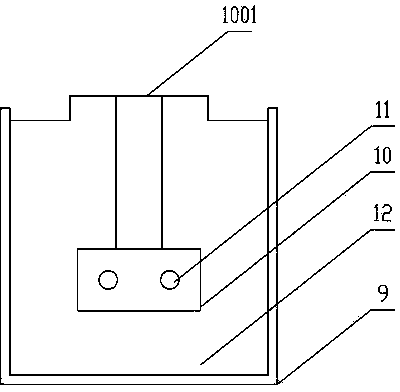

[0038] A method for testing the thermal performance of an LED heat sink. The end surface of a heating block 10 made of pure copper is used as a heating surface 1001 to simulate the heat source of an LED chip. The heating block 10 is embedded with an electric heating tube 11, which is placed in the containing box 9 and is surrounded by a heat insulating material 12, so that the heat generated by the electric heating tube 11 can be almost completely transferred to the end surface of the copper block, and the power supply connected to the electric heating tube 11 can be adjusted. The magnitude of the current can change the magnitude of the heat flux reaching the heating surface 1001, thereby simulating LED chips with different powers.

[0039] The radiator 13 to be tested is placed between the heating surface 1001 and the screw 7, the heating surface of the radiator is aligned with the heating surface 1001 of the copper block, and the centra...

Embodiment 2

[0042] Such as Figure 1-5 shown.

[0043] A heat performance testing device for an LED radiator includes a rotating device, a fixing device and a heat source simulation device.

[0044] The rotating device includes a base 1, a supporting frame 2 and a U-shaped rotating frame 3. The two supporting frames 2 are fixed on both ends of the base 1 with screws. The opposite second hinged hole 301 can be hinged by bolts and nuts. On the support frame, with the first hinge hole 201 as the center, a plurality of first positioning holes 202 are evenly distributed within 90°, the number of which can be set according to the required test angle, and the positions of the positioning holes on the support frames 2 on both sides are arranged symmetrically. The two ends of the swivel frame 3 also have a corresponding second positioning hole 302, one of the first and second positioning holes is opposite, and the stop pin 4 is inserted, so that the swivel frame can be rotated and fixed at a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com