The slag lowering device that prevents the amount of slag dropping from being controlled by the slag cooler

A technology of slag cooling machine and slag volume, which is applied to the direction of burning fuel in molten state, lighting and heating equipment, fluidized bed combustion equipment, etc., and can solve the problems that the slag volume cannot be solved and is not controlled by the slag cooling machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

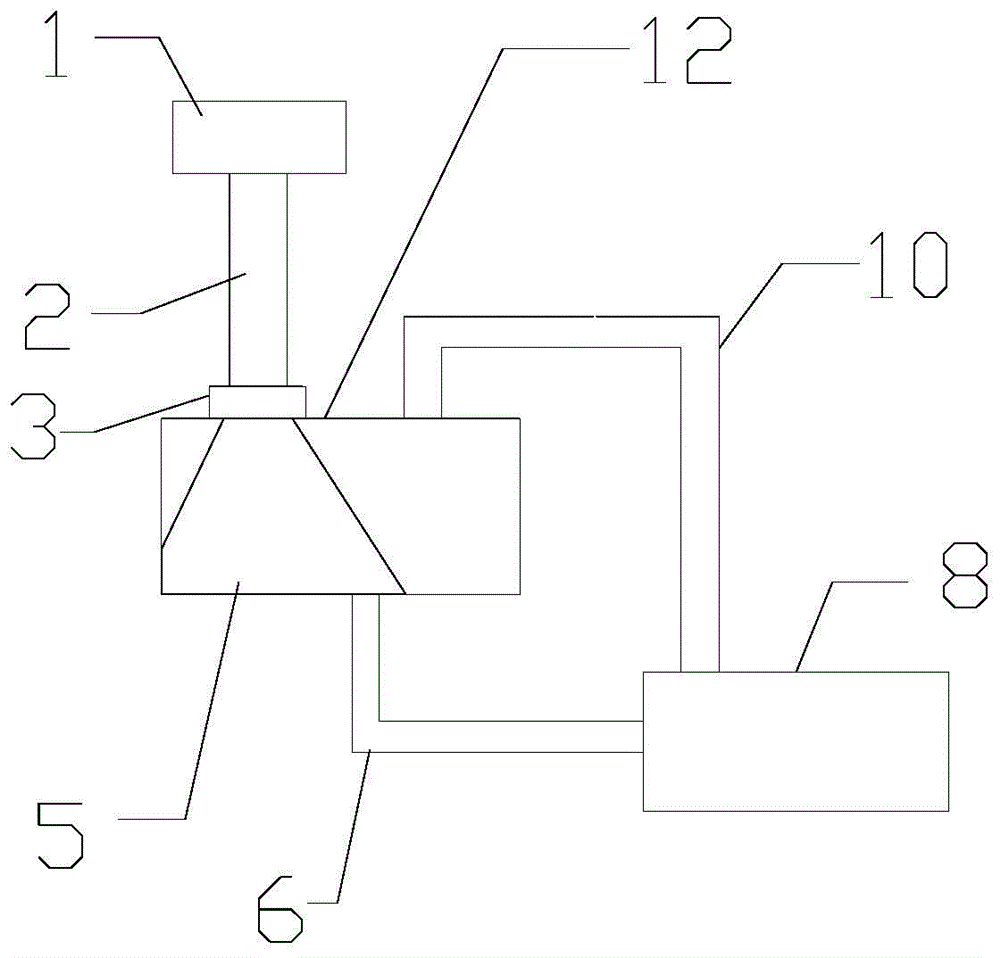

[0034] like figure 1 As shown, a slag lowering device that prevents the amount of slag lowering from being controlled by the slag cooler includes an upper section 2 of the slag lowering pipe whose upper end is connected to the slag lowering port 1 of the boiler; The bottom of the buffer bin 12 is also connected with the lower section 6 of the lower slag pipe, and the opening where the bottom of the buffer bin 12 communicates with the lower section 6 of the lower slag pipe is at the top of the ash discharged from the upper section 2 of the lower slag pipe to block the lower slag The other end of the lower section 6 of the lower slag pipe is connected to the slag cooler 8 when the lower outlet of the upper section 2 of the pipe is within the range of the bottom of the ash; It is connected with the cold slag machine 8.

[0035] The upper section 2 of the lower slag pipe is connected with the buffer bin 12 through the three-dimensional expansion joint 3 . The pressure balance pi...

Embodiment 2

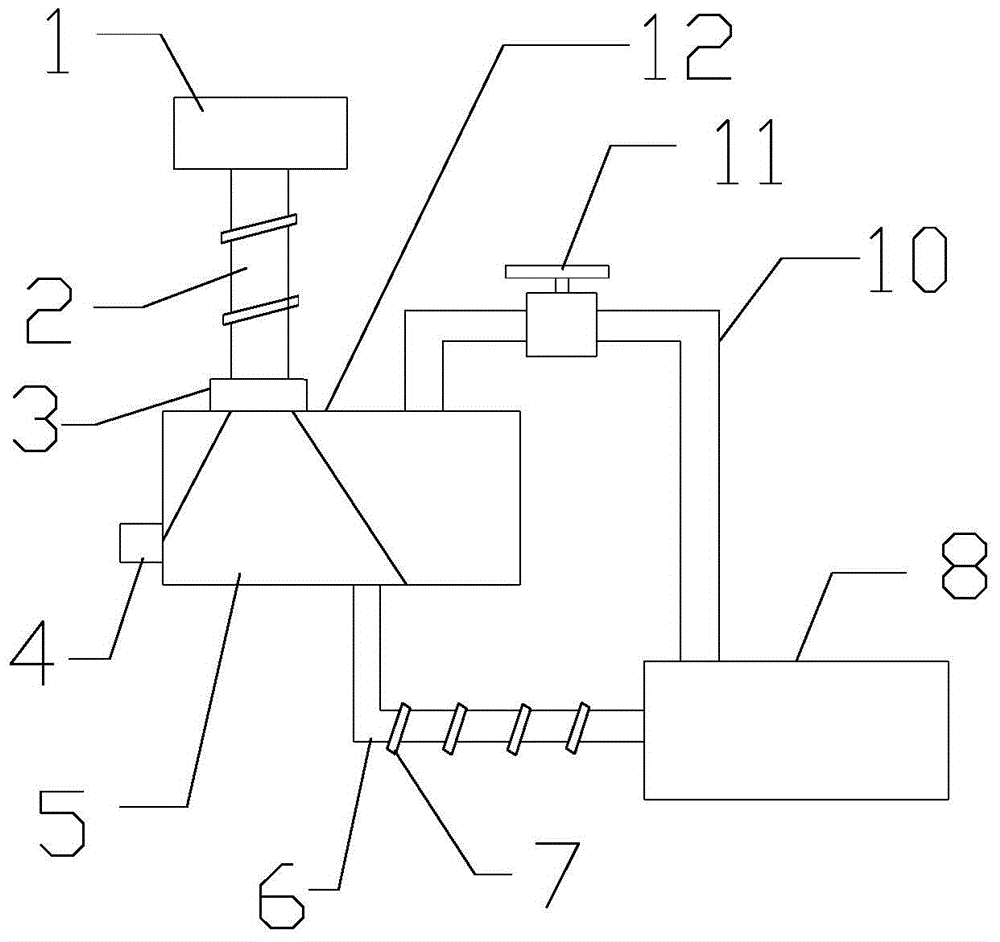

[0042] like figure 2As shown, a slag lowering device that prevents the amount of slag lowering from being controlled by the slag cooler includes an upper section 2 of the slag lowering pipe whose upper end is connected to the slag lowering port 1 of the boiler; The bottom of the buffer bin 12 is also connected with the lower section 6 of the lower slag pipe, and the opening where the bottom of the buffer bin 12 communicates with the lower section 6 of the lower slag pipe is at the top of the ash discharged from the upper section 2 of the lower slag pipe to block the lower slag The other end of the lower section 6 of the lower slag pipe is connected to the slag cooler 8 when the lower outlet of the upper section 2 of the pipe is within the range of the bottom of the ash; It is connected with the cold slag machine 8.

[0043] The upper section 2 of the lower slag pipe is connected with the buffer bin 12 through the three-dimensional expansion joint 3 . A valve 11 is arranged ...

Embodiment 3

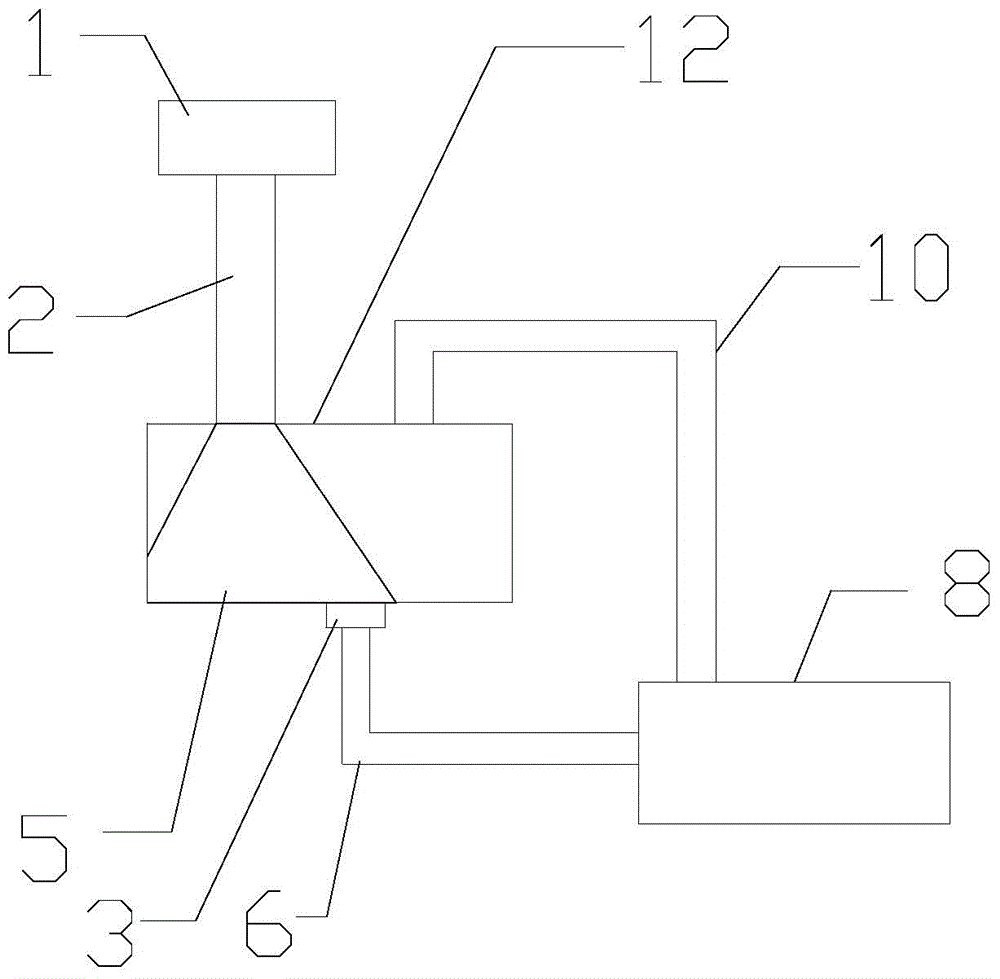

[0051] like image 3 As shown, a slag lowering device that prevents the amount of slag lowering from being controlled by the slag cooler includes an upper section 2 of the slag lowering pipe whose upper end is connected to the slag lowering port 1 of the boiler; The bottom of the buffer bin 12 is also connected with the lower section 6 of the lower slag pipe, and the opening where the bottom of the buffer bin 12 communicates with the lower section 6 of the lower slag pipe is at the top of the ash discharged from the upper section 2 of the lower slag pipe to block the lower slag The other end of the lower section 6 of the lower slag pipe is connected to the slag cooler 8 when the lower outlet of the upper section 2 of the pipe is within the range of the bottom of the ash; It is connected with the cold slag machine 8.

[0052] The staggered arrangement of the lower section 6 of the lower slag pipe and the upper section 2 of the lower slag pipe can delay the falling speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com