Split electric wheel system with excitation-free electromagnetic parking braking device

A braking device, electromagnetic brake technology, applied in the direction of brake type, axial brake, brake actuator, etc. Dynamic failure, high reliability, and the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

[0029] The overall composition of the split electric wheel system with non-excitation electromagnetic parking brake device is as follows:

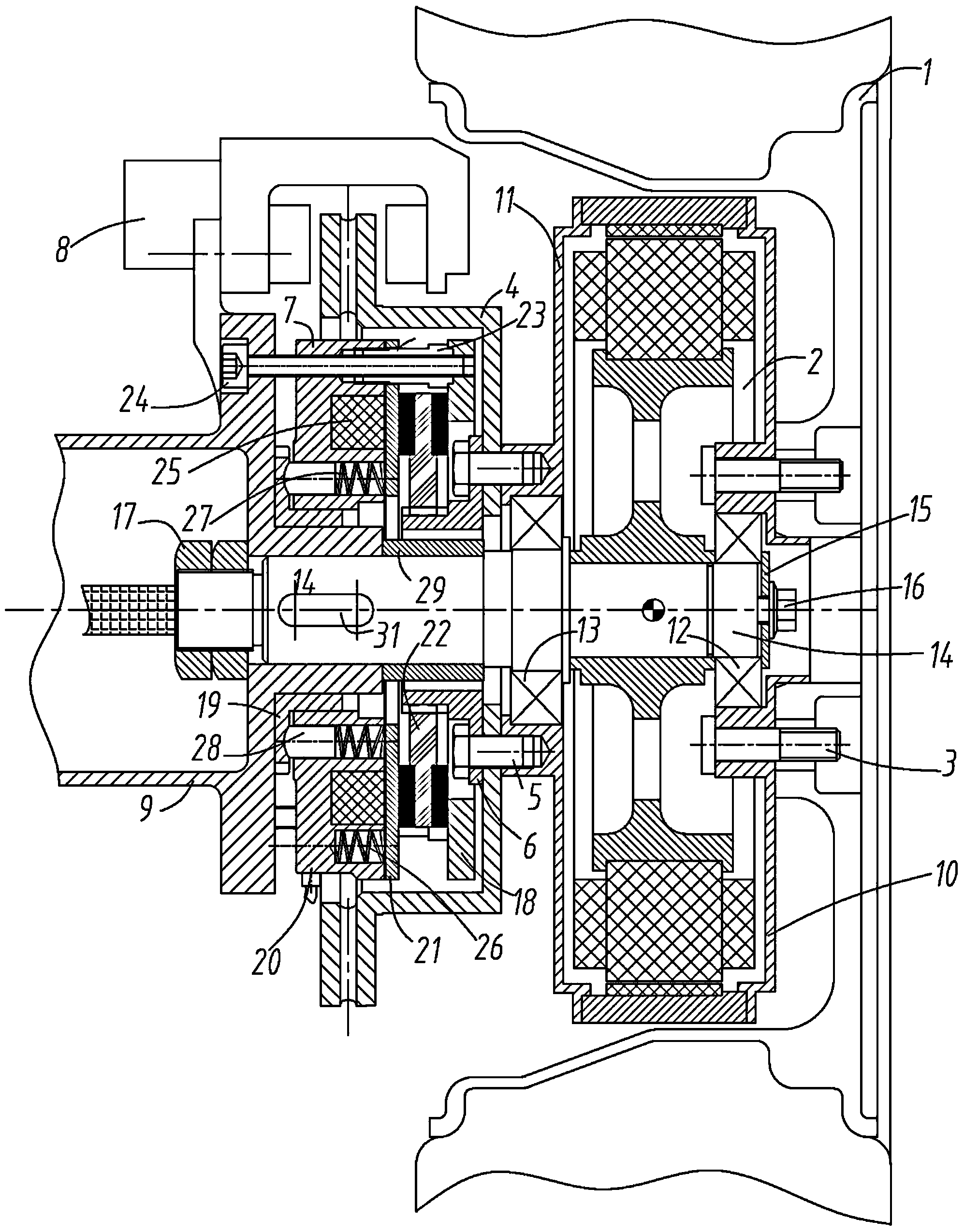

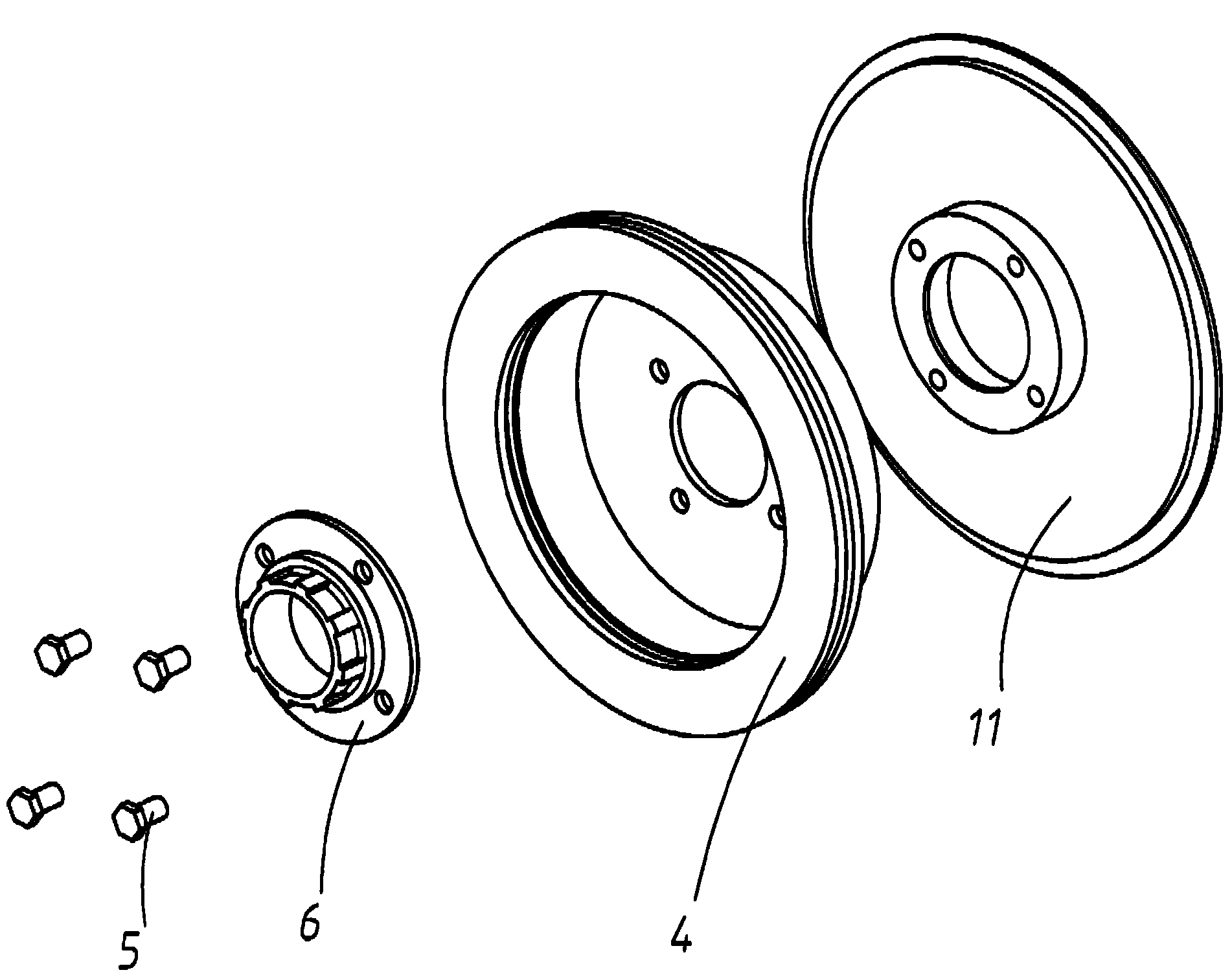

[0030] refer to figure 1, the split type electric wheel system with non-excitation electromagnetic parking brake device has wheel 1, hub motor 2, rim bolt 3, brake disc 4, brake disc bolt 5, motor housing conversion flange 6, Electromagnetic brake 7, brake caliper 8, suspension beam end 9, sleeve 29.

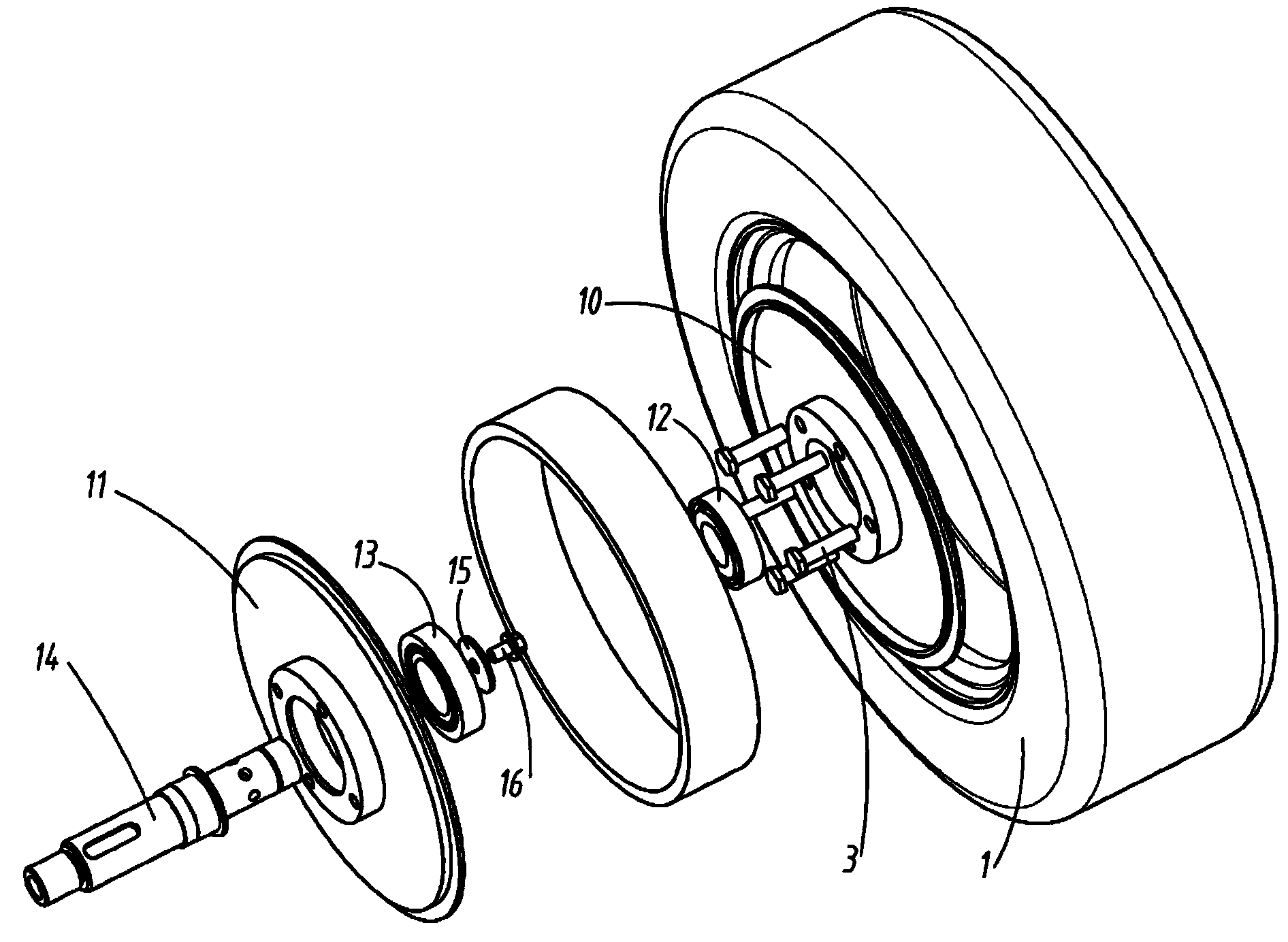

[0031] Hub motor 2 has hub motor outer casing 10, hub motor inner casing 11, motor outer tapered roller bearing 12, motor inner tapered roller bearing 13, motor shaft 14, shaft end retaining ring 15, shaft end bolt 16, shaft End double nut 17, flat key 31.

[0032] The electromagnetic brake 7 has an electromagnetic brake end cover 18, a braking torque adjustment ring 19, an electromagnetic brake housing 20, a magnetic yoke 21, a friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com