Rotating electric machine and compressor

A technology for rotating electrical machines and compressors, which is applied in the direction of machines/engines, mechanical equipment, electric components, etc., and can solve problems such as damage to insulating films, and achieve the effects of reducing stress, suppressing the increase of iron loss, and facilitating passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

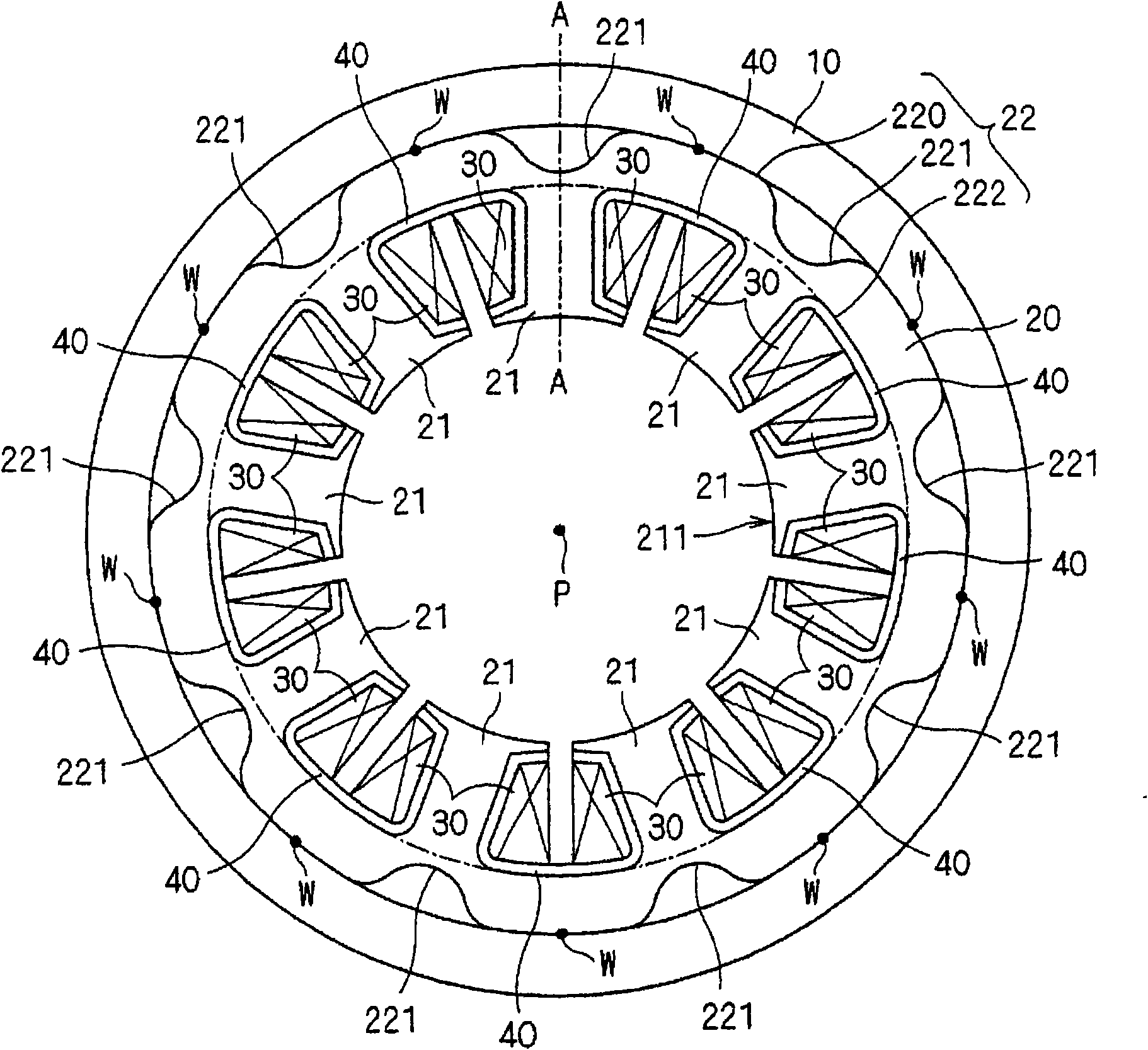

[0033] A rotating electric machine according to an embodiment of the present invention will be described. figure 1 is a schematic configuration diagram of a rotating electrical machine in a cross section perpendicular to the rotation axis P. FIG.

[0034] This rotating electric machine 1 has a case 10 , a stator core 20 , a coil 30 , and an insulating film 40 .

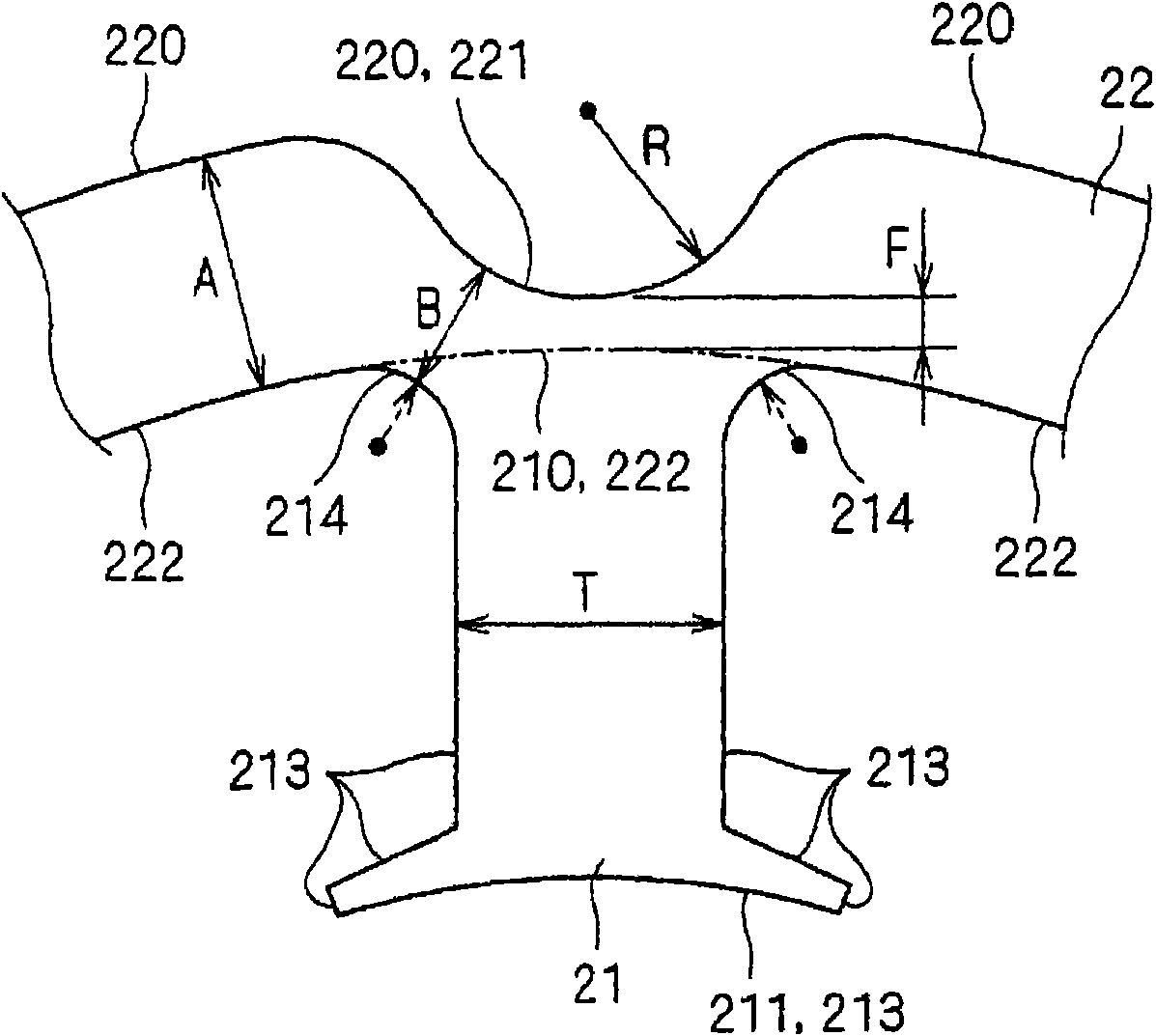

[0035] The stator core 20 has a plurality of teeth 21 and a back yoke 22 . The plurality of teeth 21 are arranged radially around the rotation axis P, and have one end on the opposite side of the rotation axis P in the radial direction around the rotation axis P. figure 1 In , nine teeth 21 are illustrated.

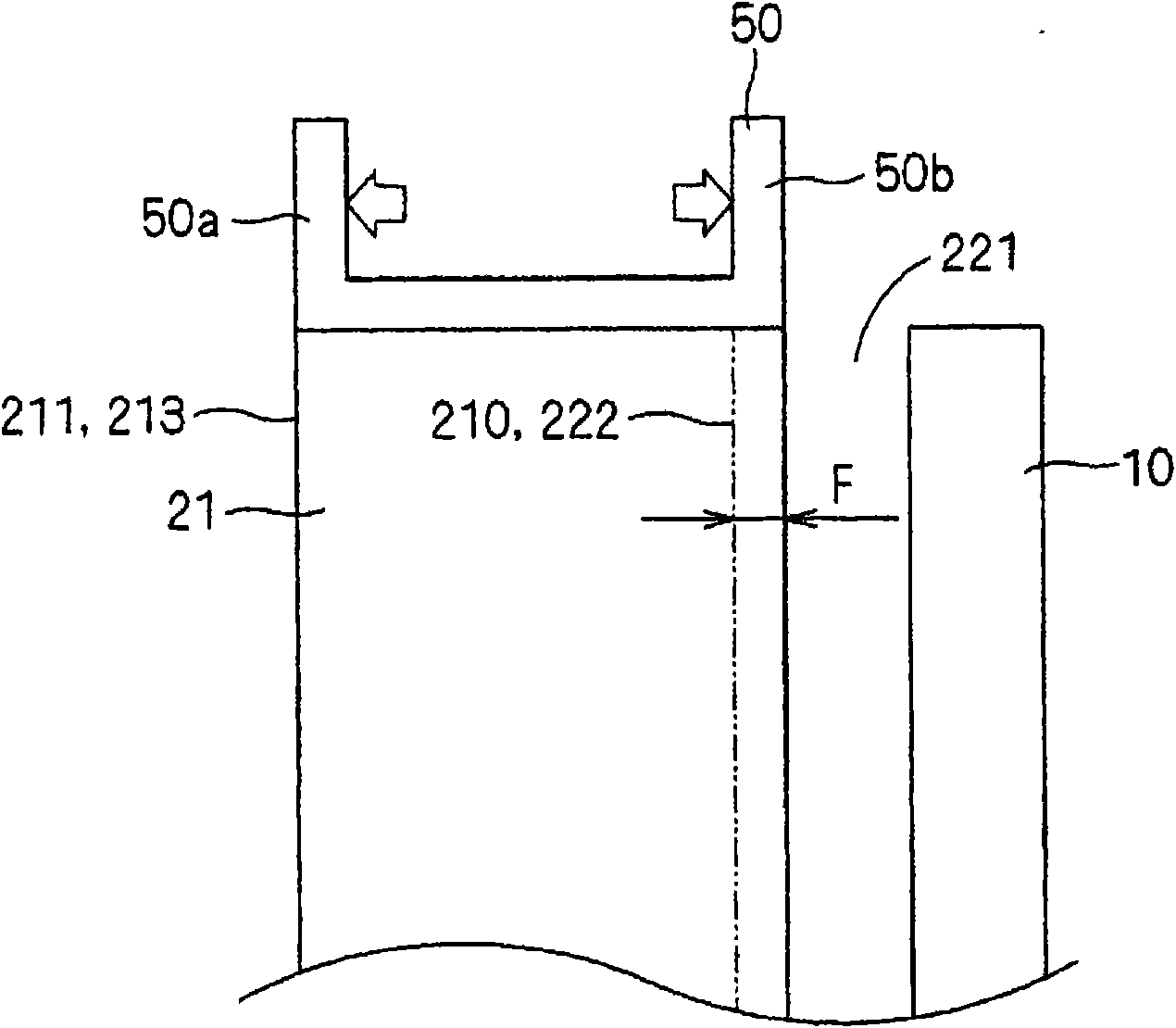

[0036] The back yoke 22 has an annular outer peripheral surface 220 and a cylindrical inner peripheral surface 222 connecting the one ends thereof. On the outer peripheral surface 220 , a plurality of recesses (hereinafter referred to as notches) 221 opening radially toward the opposite side of the rotation ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com