Industrial dewaxing agent

A wax remover, an industrial technology, applied in the field of wax remover to remove residual wax stains on stainless steel surface after polishing, can solve the problems of unsatisfactory wax removal effect, stained film on products, and difficulty in achieving clean and bright. Excellent wax effect, harmless to the human body and environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

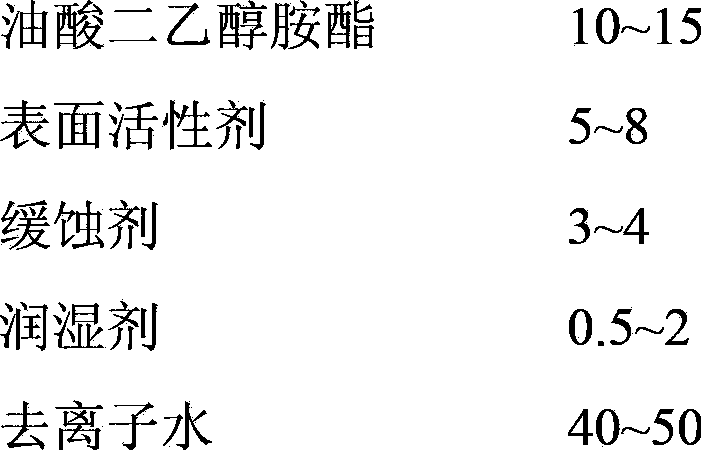

[0021] An industrial wax remover, consisting of the following components by mass:

[0022]

[0023] In the technical solution of this embodiment, the diethanolamine oleate is a reaction product of oleic acid and diethanolamine in a molar ratio of 1:2.

[0024] In the technical solution of this embodiment, the surfactant is Span 60.

[0025] In the technical solution of this embodiment, the corrosion inhibitor is benzotriazole.

Embodiment 2

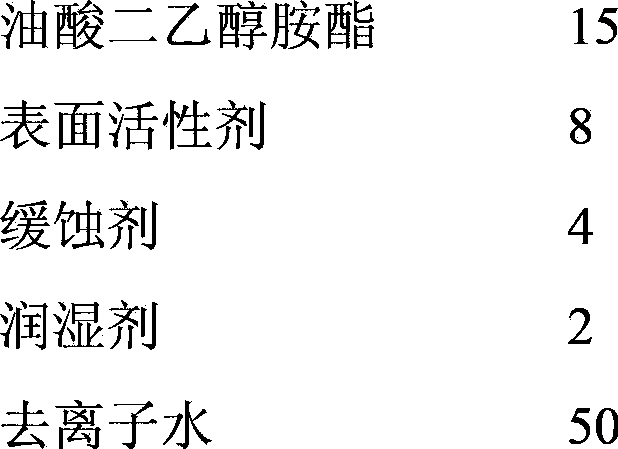

[0027] An industrial wax remover, consisting of the following components by mass:

[0028]

[0029] In the technical solution of this embodiment, the diethanolamine oleate is a reaction product of oleic acid and diethanolamine in a molar ratio of 1:2.

[0030] In the technical solution of this embodiment, the surfactant is Tween 40.

[0031] In the technical solution of this embodiment, the corrosion inhibitor is α-hydroxybenzotriazole.

Embodiment 3

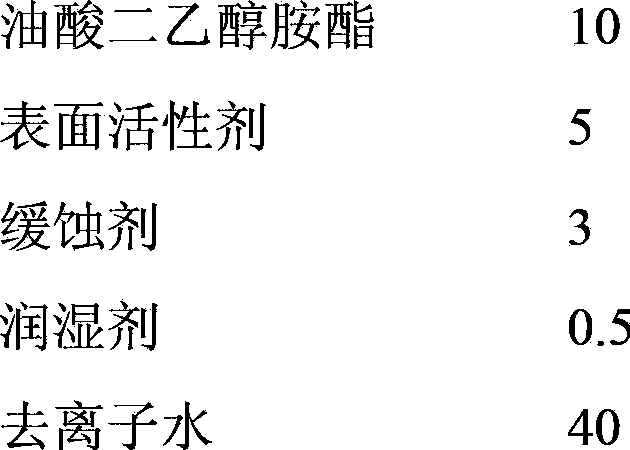

[0033] An industrial wax remover, consisting of the following components by mass:

[0034]

[0035] In the technical solution of this embodiment, the diethanolamine oleate is a reaction product of oleic acid and diethanolamine in a molar ratio of 1:2.

[0036] In the technical solution of this embodiment, the surfactant is Span 80.

[0037] In the technical solution of this embodiment, the corrosion inhibitor is petroleum sulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com