Gasification chamber with top-mounted nozzles and gasification furnace with gasification chamber

A technology of gasification chamber and gasification furnace, which is applied in the direction of granular/powdered fuel gasification, etc., and can solve problems such as overtemperature of the wall surface or low carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

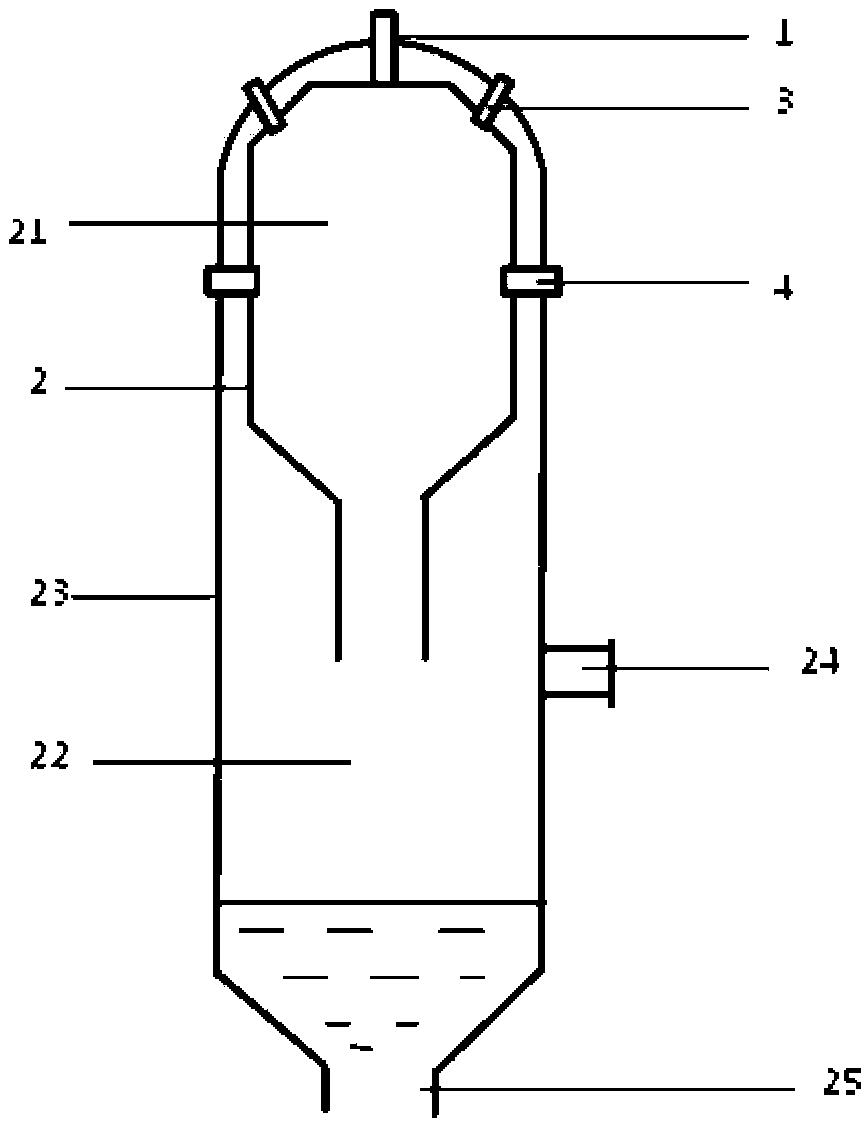

Embodiment 1

[0085] exist figure 2 In , only the main nozzle operates, and neither the top auxiliary nozzle nor the side wall auxiliary nozzle operates. At this time, the recirculation zone in the gasification chamber is relatively large, extending from the top of the furnace to the lower part of the furnace. This operating condition is suitable for coal with moderate ash content (10~25%), ash melting point of 1300~1450°C, good viscosity-temperature characteristics, and high carbon conversion rate and stable furnace conditions can be achieved only when the main nozzle is running.

Embodiment 2

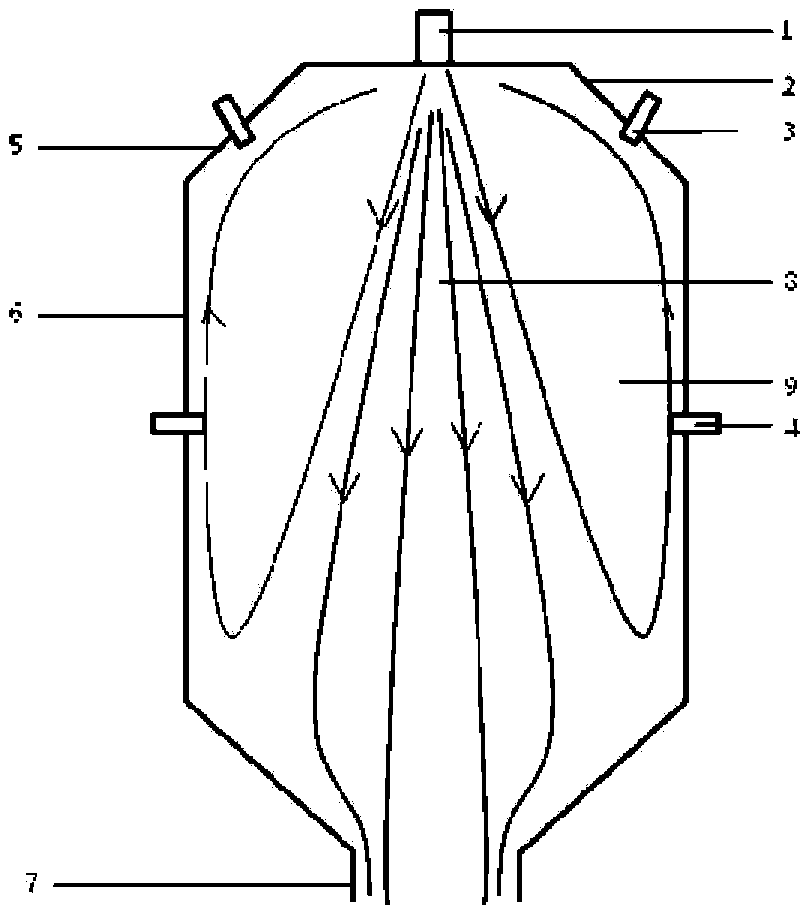

[0087] exist image 3 , the main nozzle and the side wall auxiliary nozzle operate simultaneously. This operating condition is used to improve the situation of low carbon conversion rate. For example, when coal with low ash and narrow viscosity-temperature characteristics is used, the operating temperature is low and the range of high temperature zone is small, so that the effective residence time of pulverized coal particles in the high temperature zone is biased. Low resulting in low carbon conversion rate. In the figure, the auxiliary nozzles on the side wall are located in the straight section of the wall of the gasification chamber, and 4 are evenly arranged in the horizontal direction. The angle between the axis of the nozzle and the radial direction of the gasification furnace is 35 degrees. Each auxiliary nozzle on the side wall has a double-channel structure, the central channel 14 leads to the oxygen-containing premixed gas, and the outer channel 15 leads to the ash...

Embodiment 3

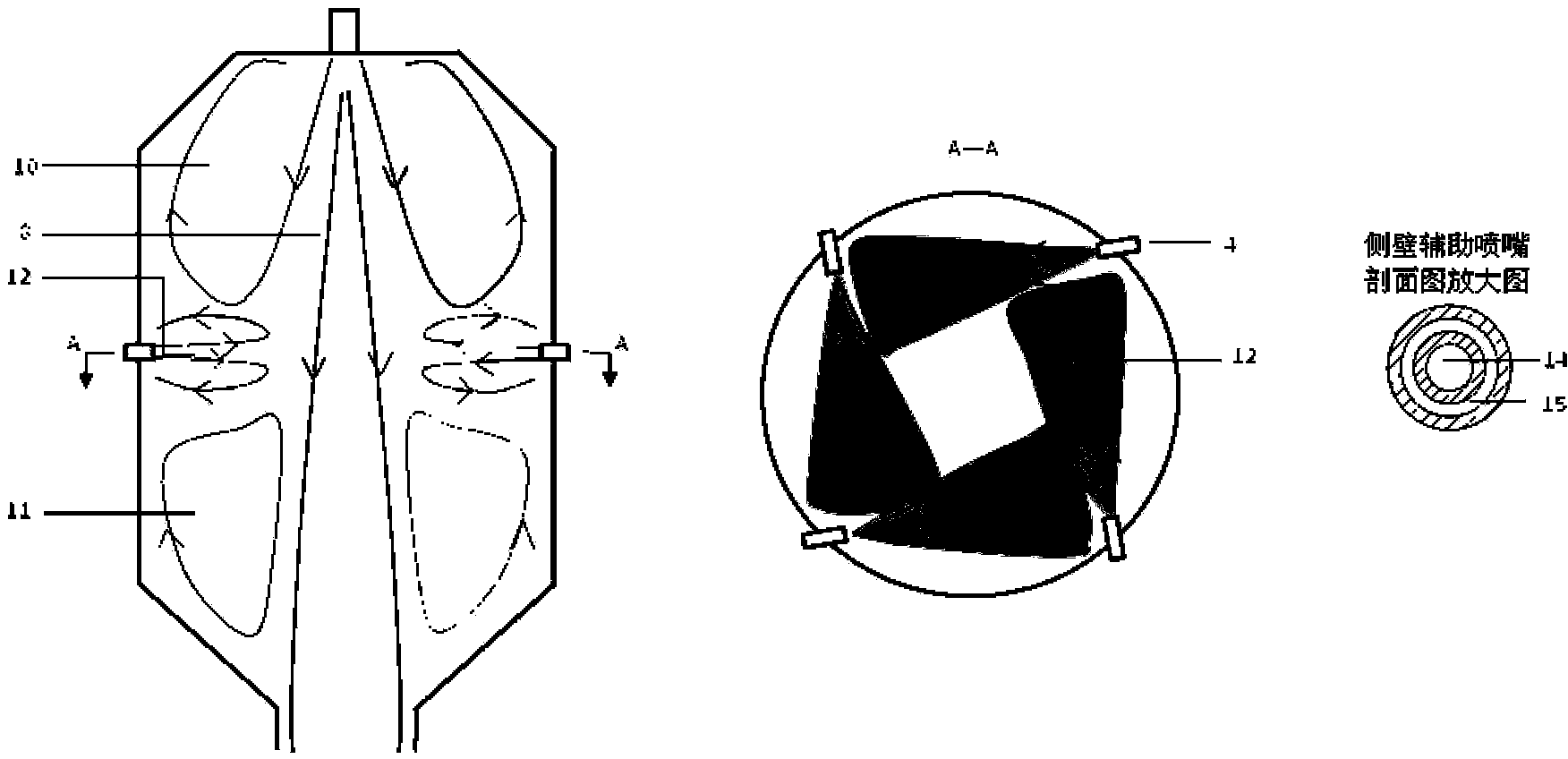

[0089] exist Figure 4 , the main nozzle and the top auxiliary nozzle operate simultaneously. This operating condition is used to improve the overheating of the wall of the gasification chamber, such as the high temperature of the wall of the gasification chamber caused by high operating temperature when coal with high ash and high ash melting point is used. Figure 4 There are 4 auxiliary nozzles on the middle top evenly arranged in the horizontal direction, and the arrangement method is opposite. The inside of the nozzle is a flat duckbill-shaped channel 16, and the cross-section 13 of the spray area 13 is oblate. Since the ejection medium does not contain oxygen, the formed jet zone is a low-temperature zone, which isolates the flame from the wall and reduces the temperature near the wall of the gasification chamber. Especially when the injection medium is ash-containing crude syngas, due to the absorption and heat dissipation of the particles, the temperature of the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com