Surface modification method for inorganic powder

An inorganic powder and surface modification technology, which is applied in the treatment of dyed polymer organic compounds and fibrous fillers, etc., can solve problems such as difficult industrialization, unrecognized compatibility, and complicated modification process, so as to reduce environmental pollution. Effects of pollution, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Formula: 100 parts of inorganic powder, 1 part of ethylene-vinyl alcohol copolymer (the molar content of ethylene is 70%), and 5 parts of glycerin. The inorganic powder is nanometer calcium carbonate.

[0025] The surface modification method of inorganic powder comprises the following steps:

[0026] (1) Crush ethylene-vinyl alcohol copolymer into 20-mesh powder, dry at 90°C for 8 hours, and set aside;

[0027] (2) Dry the inorganic powder at 90°C for 1 hour;

[0028] (3) After uniformly mixing the dried ethylene-vinyl alcohol copolymer powder with glycerin, the dried inorganic powder was activated at 165°C for 10 min to obtain the surface-modified inorganic powder.

Embodiment 2

[0030] Formula: 100 parts of inorganic powder, 6 parts of ethylene-vinyl alcohol copolymer (30% ethylene molar content), 30 parts of glycerin. The inorganic powder is a superfine inorganic powder mixture of marble, potassium feldspar, albite and carbon black (mass ratio is 1:1:1:1).

[0031] The surface modification method of inorganic powder comprises the following steps:

[0032] (1) Crush ethylene-vinyl alcohol copolymer into 100-mesh powder, dry at 92°C for 8 hours, and set aside;

[0033] (2) Dry the inorganic powder at 120°C for 3 h;

[0034] (3) After mixing the dried ethylene-vinyl alcohol copolymer powder and glycerol evenly, the dried inorganic powder was activated at 200°C for 30 min to obtain the surface-modified inorganic powder.

Embodiment 3

[0036] Formula: 100 parts of inorganic powder, 3 parts of ethylene-vinyl alcohol copolymer (the molar content of ethylene is 44%), and 15 parts of glycerin.

[0037] The inorganic powder is superfine inorganic powder of calcium oxide, calcium hydroxide, kaolin, talcum powder and glass microspheres (mass ratio is 1:1:1:1:1).

[0038] The surface modification method of inorganic powder comprises the following steps:

[0039] (1) Crush ethylene-vinyl alcohol copolymer into 60-mesh powder, dry at 91°C for 8 hours, and set aside;

[0040] (2) Dry the inorganic powder at 105°C for 2 h;

[0041] (3) After uniformly mixing the dried ethylene-vinyl alcohol copolymer powder with glycerin, the dried inorganic powder was activated at 175°C for 20 minutes to obtain a surface-modified inorganic powder.

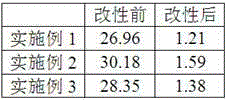

[0042] Interfacial tension (mJ / m) of inorganic powder and polypropylene after the process of the inventive method 2 )as follows:

[0043]

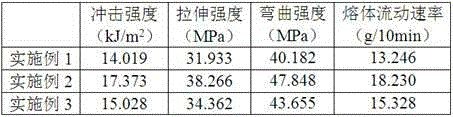

[0044] Add 40 parts of the modified inorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com