Preparation method of dihydrate hexamethylene-1,6-disodium dithiosulfate

A technology of disodium dithiosulfate and hexamethylene dihydrate is applied in the field of preparation of hexamethylene dihydrate 1,6-dithiosulfate disodium salt, which can solve the problem of low reaction yield and adaptability , long reaction time and other problems, to achieve the effect of high reaction yield, simple and convenient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

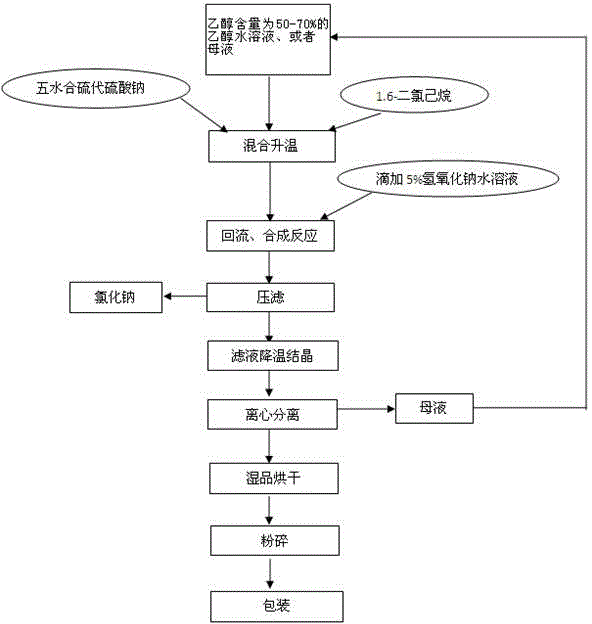

Image

Examples

Embodiment 1

[0020] Into the 2000L reaction kettle that is equipped with stirring, reflux condenser, online pH meter, high level tank, drop into 1020kg and prepare ethanol aqueous solution that ethanol content is 60%, 420kg sodium thiosulfate pentahydrate, 120kg 1.6-dichlorohexane mix and stir . Pump 50L of prepared 5% sodium hydroxide aqueous solution into the high-level tank, and the pH value is measured at about 8.0 at this time. Begin to heat up, reflux reaction, the temperature is at 84 ℃. With the progress of the reaction, the online pH meter found that the pH value was constantly decreasing. At this time, 5% aqueous sodium hydroxide solution was added dropwise to keep the pH value between 7.5-8.0. After about 7 hours of reflux reaction, no 5% aqueous sodium hydroxide solution was added dropwise at this time, and the pH of the reaction solution was between 7.5-8.0, and basically no longer dropped. At this time, about 42 L of 5% sodium hydroxide aqueous solution was used. Reduc...

Embodiment 2

[0022] In the 2000L reactor that stirring, reflux condenser, on-line pH meter, high level tank are installed, drop into by centrifuging and reclaiming mother liquor 1040kg in the implementation example 1, add 60kg95% ethanol, add 40kg purified water, drop into 384kg pentahydrate thiosulfate again Sodium sulfate, drop into 120kg 1.6-dichlorohexane and mix and stir. Pump 50L of prepared 5% sodium hydroxide aqueous solution into the high-level tank, slowly add 5% sodium hydroxide aqueous solution to the reaction mixture, and adjust the pH value between 7.5-8.0. Begin to heat up, reflux reaction, the temperature is at 85 ℃. With the progress of the reaction, the online pH meter found that the pH value was constantly decreasing. At this time, 5% aqueous sodium hydroxide solution was added dropwise to keep the pH value between 7.5-8.0. After about 7 hours of reflux reaction, it was found that colorless transparent crystals were precipitated (sodium chloride crystals). At this time,...

Embodiment 3

[0024] In the 2000L reactor that is equipped with stirring, reflux condenser, on-line pH meter, high level tank, drop into 1020kg and prepare ethanol aqueous solution that ethanol content is 50%, 653kg sodium thiosulfate pentahydrate, 204kg 1.6-dichlorohexane are mixed and stirred . Pump 250L of prepared 1% sodium hydroxide aqueous solution into the high-level tank, and the pH value at this time is measured to be around 8.0. Begin to heat up, reflux reaction, the temperature is at 80 ℃. Along with the progress of the reaction, the online pH meter found that the pH value was constantly decreasing. At this time, 1% aqueous sodium hydroxide solution was added dropwise to keep the pH value at 7.5. After about 7 hours of reflux reaction, no 1% aqueous sodium hydroxide solution was added dropwise at this time, and the pH of the reaction solution was at 7.5, which basically did not drop. At this time, about 210 L of 1% sodium hydroxide aqueous solution was used. Reduce the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com