Method for preparing chlorobenzene, p-dichlorobenzene and o-dichlorobenzene in benzene chlorination

A technology for p-dichlorobenzene and o-dichlorobenzene is applied in the field of preparation of chemical raw materials and can solve the problems of increased amount of by-product polychlorinated benzene, low production capacity, unsuitable for large-scale production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The main products are p-dichlorobenzene and o-dichlorobenzene.

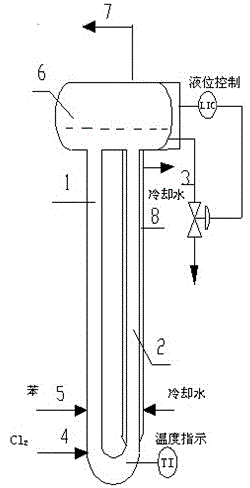

[0035] In the outer loop reactor with an aspect ratio of 20 and a tube diameter ratio of 1, the water (anhydrous calcium chloride) dried For benzene with water content ≦100×10-6 weight fraction, the catalyst is ferric trisulfide, 0.08 (W / %) is suspended in benzene, and at the same time, the volume of loop reactor (air lift tube) per cubic meter is 400m3 / h ( Chlorine gas was introduced into the reactor at a speed of 17.9kmole), and the jacket cooling water was opened to adjust the amount of cooling water to control the temperature of the material in the reactor at 45°C. Liquid, the discharge valve continuously adjusts the discharge volume to ensure that the liquid level of the gas-liquid separator is at a certain position. The hydrogen chloride produced by the reaction is separated into gas and liquid, and enters the graphite condenser to separate the entrained benzene and chloride solution. The benzene a...

Embodiment 2

[0040] The main products are p-dichlorobenzene and o-dichlorobenzene, and the co-production of chlorinated benzene has a large proportion.

[0041] In the outer loop reactor with an aspect ratio of 20 and a tube diameter ratio of 1, the water is passed through (anhydrous calcium chloride) drying For benzene with water content ≦100×10-6 weight fraction, the catalyst is ferric trisulfide, 0.07 (W / %) is suspended in benzene, and at the same time, the volume of the loop reactor (air lift tube) per cubic meter is 609m3 / h ( Chlorine gas is introduced into the reactor at a speed of 27.20 kmole), and the jacket cooling water is opened to adjust the amount of cooling water to control the temperature of the material in the reactor at 50°C. Liquid, the discharge valve continuously adjusts the discharge volume to ensure that the liquid level of the gas-liquid separator is at a certain position. The hydrogen chloride produced by the reaction is separated into gas and liquid, and enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com