Separation method of toluene, methanol, isopropanol and dimethyl carbonate mixture

A technology of dimethyl carbonate and separation method, applied in the purification/separation of carbonate/haloformate, preparation of organic compounds, distillation purification/separation, etc., can solve separation difficulties, environmental pollution, and processing costs higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

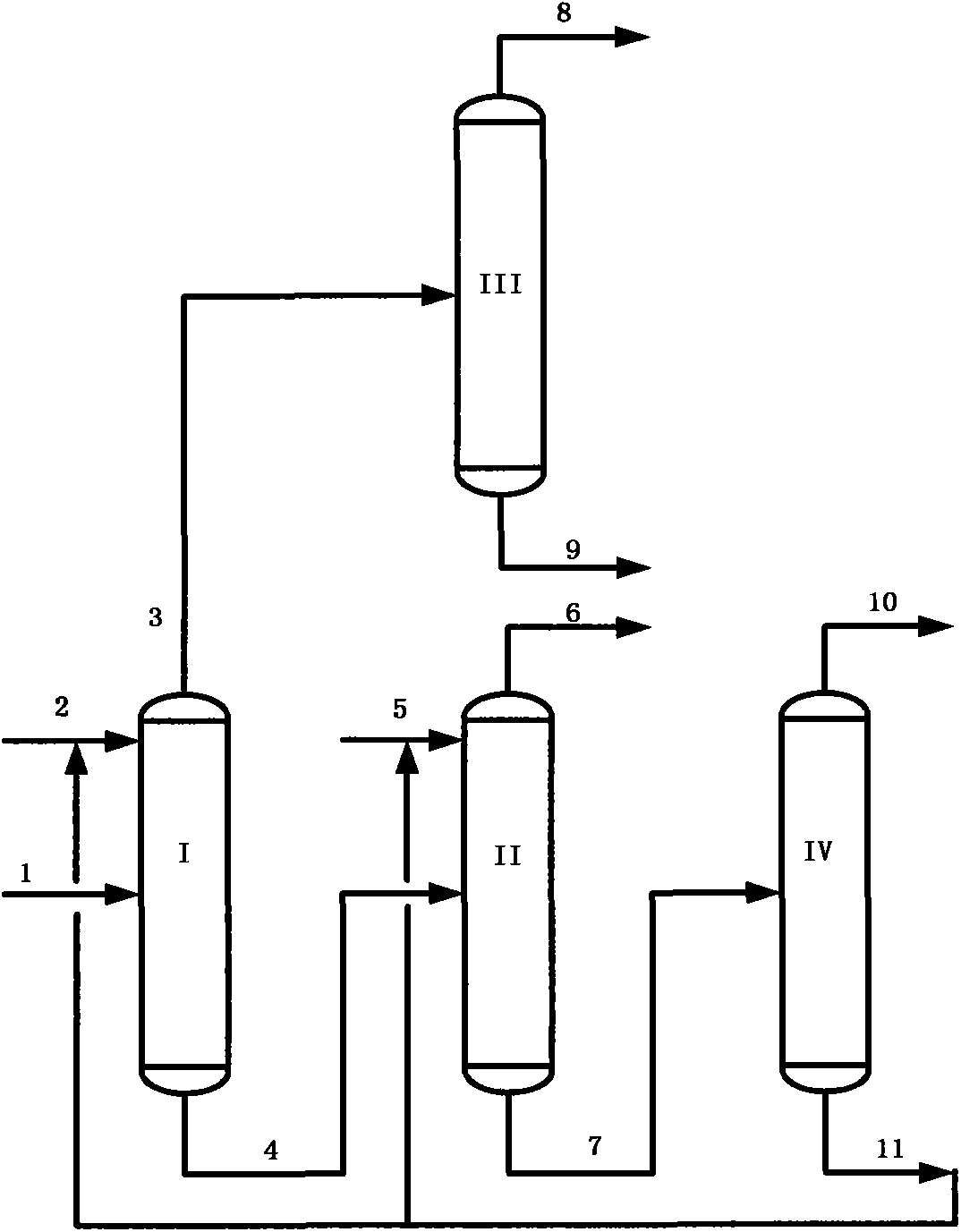

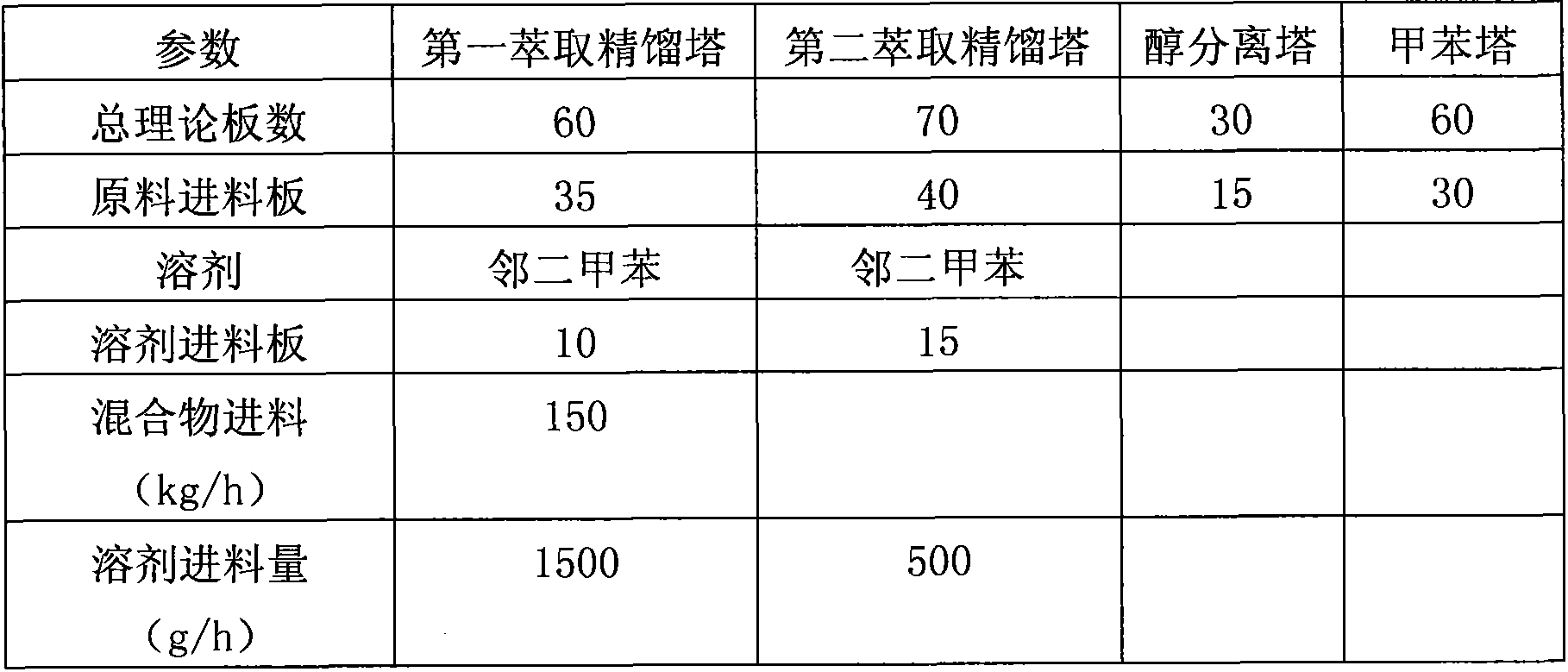

[0038] Embodiment 1 A kind of separation method of toluene, methyl alcohol, Virahol, dimethyl carbonate mixture, the steps are as follows:

[0039] (1) The waste solvent containing toluene, methyl alcohol, isopropanol, dimethyl carbonate mixture first enters the middle part of the first extractive distillation tower, and the first solvent enters the first extractive distillation tower top, and in the first extractive distillation tower Realize the separation of alcohol and dimethyl carbonate, toluene, methanol and isopropanol mixture are obtained at the top of the tower, and the bottom of the tower is a mixture containing solvent, dimethyl carbonate and toluene;

[0040] (2) methanol and isopropanol mixture at the top of the first extractive distillation tower enter the alcohol separation tower again, the top of the alcohol separation tower obtains methanol, and the tower still obtains isopropanol;

[0041] (3) the first extractive distillation column tower still solvent, tolu...

Embodiment 2

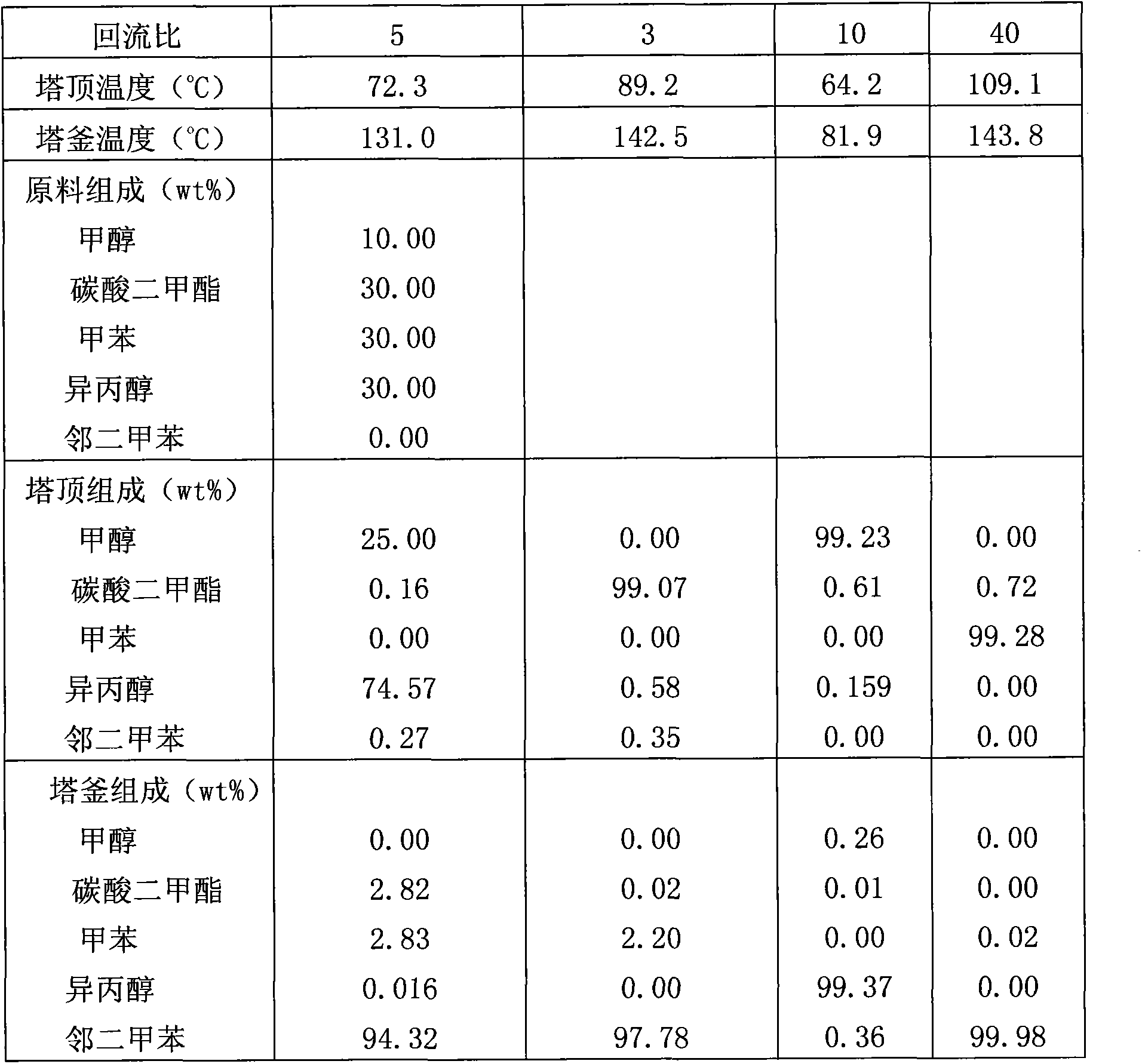

[0048] Embodiment 2 A kind of separation method of toluene, methyl alcohol, Virahol, dimethyl carbonate mixture, step is identical with embodiment 1. The raw materials are waste materials containing 10% by mass percentage of methanol, 30% of dimethyl carbonate, 30% of toluene, and 30% of isopropanol. The extraction and rectification solvent uses m-xylene. The first extractive distillation column has 60 theoretical plates, and the second There are 70 theoretical plates in the extractive distillation tower, 30 theoretical plates in the alcohol separation tower, and 60 theoretical plates in the toluene tower.

[0049] Table 2 is the solvent separation waste with m-xylene

[0050]

[0051]

[0052] As can be seen from the above table 2, the separation of methyl alcohol, dimethyl carbonate, isopropanol and toluene can be realized by using m-xylene as a solvent, but the purity of dimethyl carbonate is greater than 97%, the purity of methanol is greater than 99%, and the purity...

Embodiment 3

[0053]Embodiment 3 A kind of separation method of toluene, methyl alcohol, Virahol, dimethyl carbonate mixture, step is identical with embodiment 1. The raw materials are waste materials containing 10% by mass percentage of methanol, 30% of dimethyl carbonate, 30% of toluene, and 30% of isopropanol. The extractive distillation solvent uses p-xylene. The first extractive distillation column has 60 theoretical plates, and the second There are 70 theoretical plates in the extractive distillation tower, 30 theoretical plates in the alcohol separation tower, and 60 theoretical plates in the toluene tower.

[0054] Table 3 uses p-xylene as solvent separation waste

[0055]

[0056]

[0057] As can be seen from the above table 3, the separation of methanol, dimethyl carbonate, isopropanol and toluene can be realized by using p-xylene as a solvent, but the purity of dimethyl carbonate is greater than 97%, the purity of methanol is greater than 99%, and the purity of isopropanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com