A method for advanced oxidation advanced treatment of papermaking wastewater by ferrous salt activated persulfate or monoperoxyhydrogensulfate

A technology of monoperoxyhydrogensulfate and activated persulfate, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, and wastewater treatment in processing, etc. It can solve the problem of narrow pH range, complicated operation process, and concentration of suspended solids in effluent. Advanced problems, to achieve the effect of reducing the chromaticity of the effluent, simple operation process and high activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

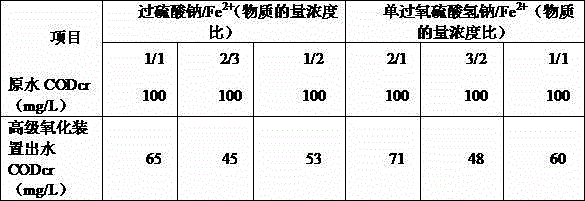

[0029] Under normal temperature conditions, take papermaking wastewater with a CODcr of 100 mg / L and a pH of 7.5 in a wastewater storage tank. like figure 1 As shown, use a metering pump to pump into the 60L advanced oxidation device at a flow rate of 30L / h, and at the same time pump a certain concentration of oxidant and ferrous sulfate heptahydrate into the water inlet pipe through a peristaltic pump to control the advanced oxidation device. The hydraulic retention time is about 2 hours. Control the influent concentration of sodium persulfate or monoperoxysodium bisulfate in the influent to 1mmol / L and 1.3mmol / L respectively. The addition amount of ferrous salt satisfies the concentration under each reaction condition shown in Table 1 respectively. CODcr detection was carried out on the overflow effluent of the advanced oxidation unit. The above-mentioned advanced oxidation device is a reaction device made of 304 stainless steel that can quickly and effectively mix incomi...

Embodiment 2

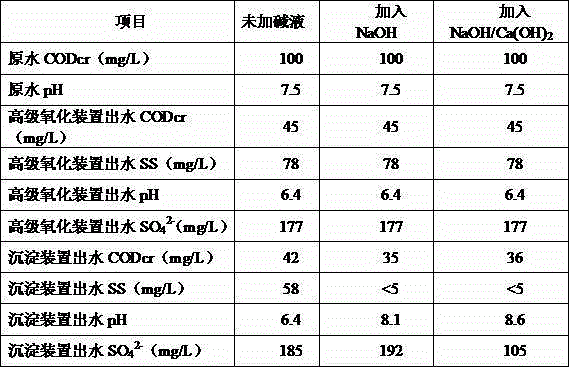

[0034] Under normal temperature conditions, take papermaking wastewater with a CODcr of 100 mg / L and a pH of 7.5 in a wastewater storage tank. like figure 1 As shown, use a metering pump to pump into the 60L advanced oxidation device at a flow rate of 30L / h, and at the same time pump a certain concentration of oxidant and ferrous sulfate heptahydrate into the water inlet pipe through a peristaltic pump to control the advanced oxidation device. The hydraulic retention time is about 2 hours. Control the influent concentration of sodium persulfate in the influent to 1mmol / L. The influent concentration of ferrous salt is 1.5mmol / L. The overflow water from the advanced oxidation device flows into the 90L sedimentation device by itself. Before the water inlet of the sedimentation device, according to the different experimental conditions in Table 2, the sodium hydroxide and calcium hydroxide solutions with appropriate concentrations are pumped in at a certain flow rate through the...

Embodiment 3

[0039] Under normal temperature conditions, take papermaking wastewater with a CODcr of 200mg / L and a pH of 7.5 in a wastewater storage tank. like figure 1 As shown, use a metering pump to pump into the 60L advanced oxidation device at a flow rate of 30L / h, and at the same time pump a certain concentration of oxidant and ferrous sulfate heptahydrate into the water inlet pipe through a peristaltic pump to control the advanced oxidation device. The hydraulic retention time is about 2 hours. Control the influent concentration of sodium persulfate in the influent to 2mmol / L. The influent concentration of ferrous salt is 3mmol / L. The overflow water from the advanced oxidation device flows into the 90L sedimentation device by itself. Before the water inlet of the sedimentation device, according to the different experimental conditions in Table 3, the peristaltic pump is pumped into the appropriate concentration of sodium hydroxide, calcium hydroxide and polychlorinated chloride at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com