Boiling chlorination furnace for preparing titanium tetrachloride by using fine-graded artificial rutile

A boiling chlorination furnace and artificial rutile technology, applied in the direction of titanium halide, etc., can solve the problems of poor technical and economic indicators, insufficient dynamic conditions, overflow of artificial rutile, etc., to achieve fluidization, easy to break, Effects of collision and friction intensification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

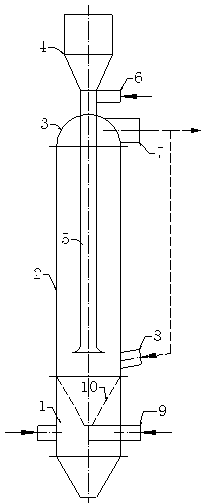

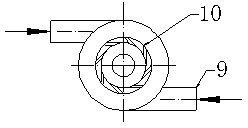

[0024] see figure 1 , the present invention utilizes fine-grained artificial rutile to prepare the ebullient chlorination furnace of titanium tetrachloride, comprising a chlorine predistributor 1, an ebullient chlorination reactor 2, an ebullient chlorination furnace top 3, a feeding tank 4, a feeding pipe 5, Feed gas inlet 6, fluidized chlorination furnace outlet 7, return material inlet 8, chlorine gas inlet 9 and chlorine gas distributor 10. The lower part of the boiling chlorination reactor 2 is a chlorine gas pre-distributor 1, and the upper part is a boiling chlorination furnace top 3, and the boiling chlorination reactor 2 and the chlorine gas pre-distributor 1 are connected through a chlorine gas distributor 10. The outer wall of the chlorine gas predistributor 1 is provided with a chlorine gas inlet 9 for tangential air inta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com