A kind of winnowing and color sorting method of tea leaves to be fermented

A technology of tea and winnowing, which is applied in the direction of chemical instruments and methods, solid separation, and separation of solids from solids with airflow, which can solve the problems of easy-to-damage tea leaves, tea leaf damage, and sorting failure. Achieve the effect of uniform tea flow, prevent sorting overload and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

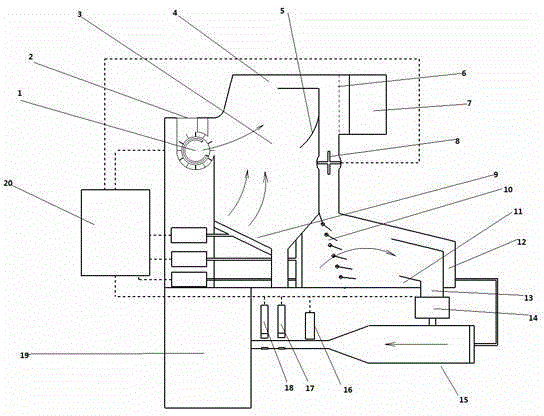

[0020] Do further description below in conjunction with accompanying drawing:

[0021] Such as figure 1 As shown, the winnowing and color sorting machine has the first winnowing structure, the second winnowing structure and the color sorting structure.

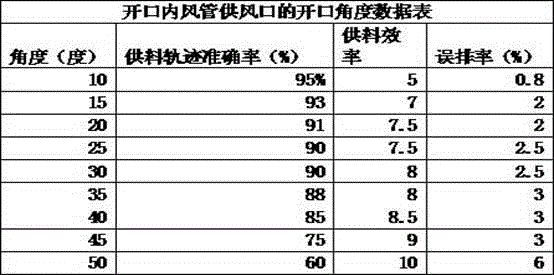

[0022] The first winnowing structure includes the wind power material wheel 1, the wind power material wheel 1 is composed of the open inner air duct and the outer material wheel, the traditional material wheel is divided into two types, one is the slowly rotating material wheel, and the tea leaves slowly enter In the winnowing room, the disadvantage of this material wheel is that the tea flow does not have a good initial speed, so the agglomerated material cannot be fully opened, which increases the difficulty of winnowing; The blades of the wheel throw the tea flow into the winnowing chamber, and the tea flow easily enters the winnowing chamber and spreads out in the winnowing chamber due to its initial speed, but this kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com