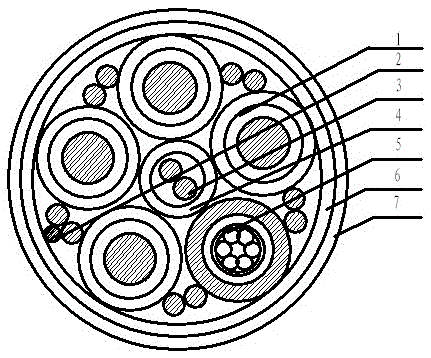

Preparation method of a field-bending and interference-resistant optoelectronic hybrid cable

An optoelectronic hybrid cable, anti-bending technology, used in cable/conductor manufacturing, cables with double-stranded/quad-stranded, insulated cables, etc., can solve the problem of poor bending resistance of optical cables, insufficient cable transmission capacity, The problem of poor bending resistance, etc., can meet the laying requirements, improve the anti-bending and anti-interference ability, and reduce the laying space and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

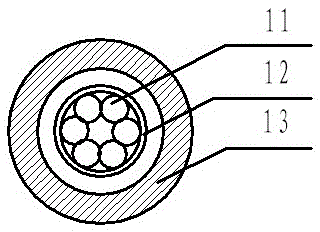

[0040] A method for preparing a field-bending and interference-resistant photoelectric hybrid cable, comprising the steps of:

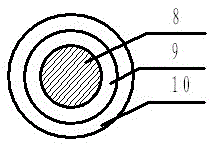

[0041] (1) Preparation of shielded insulating cable core:

[0042] a. Use a wire drawing machine or a wire and cable stranding machine to draw or twist a single or multiple silver-plated copper wires as a conductor. The twisting pitch ratio of the conductor is 8 times the outer diameter of the conductor, and the twisting direction is S direction;

[0043] b. Use a high-temperature screw extruder to extrude a layer of ethylene-tetrafluoroethylene resin as an insulating layer outside the conductor, and pass through a hot water tank, an air-cooled guide wheel passing groove, and a normal temperature water tank. The temperature of the hot water tank is 78 ° C. Air cooling The temperature of the guide wheel trough is normal temperature, the temperature of the normal temperature water tank is the ambient temperature, the temperature curves of each area of ...

Embodiment 2

[0053] A method for preparing a field-bending and interference-resistant photoelectric hybrid cable, comprising the steps of:

[0054] (1) Preparation of shielded insulating cable core:

[0055] a. Use a wire drawing machine or a wire and cable stranding machine to draw or twist a single or multiple silver-plated copper wires as a conductor. The twisting pitch ratio of the conductor is 9 times the outer diameter of the conductor, and the twisting direction is S direction;

[0056] b. Use a high-temperature screw extruder to extrude a layer of ethylene-tetrafluoroethylene resin as an insulating layer outside the conductor, and pass through a hot water tank, an air-cooled guide wheel passing groove, and a normal temperature water tank. The temperature of the hot water tank is 80 ° C. Air cooling The temperature of the guide wheel trough is normal temperature, the temperature of the normal temperature water tank is the ambient temperature, the temperature curves of each area of ...

Embodiment 3

[0066] A method for preparing a field-bending and interference-resistant photoelectric hybrid cable, comprising the steps of:

[0067] (1) Preparation of shielded insulating cable core:

[0068] a. Use a wire drawing machine or a wire and cable stranding machine to draw or twist a single or multiple silver-plated copper wires as a conductor. The twisting pitch ratio of the conductor is 10 times the outer diameter of the conductor, and the twisting direction is S direction;

[0069] b. Use a high-temperature screw extruder to extrude a layer of ethylene-tetrafluoroethylene resin as an insulating layer outside the conductor, and pass through a hot water tank, an air-cooled guide wheel passing groove, and a normal temperature water tank. The temperature of the hot water tank is 82 ° C. Air cooling The temperature of the guide wheel trough is normal temperature, the temperature of the normal temperature water tank is the ambient temperature, the temperature curves of each area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com