Test fixture of image sensor chip and with test light source

An image sensor and chip testing technology, applied to the casing of the measuring device, etc., can solve the problems of inaccurate adjustment of the brightness of the LED surface light source, cumbersome operation, low efficiency, etc., to reduce the loss of test yield, uniform brightness, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

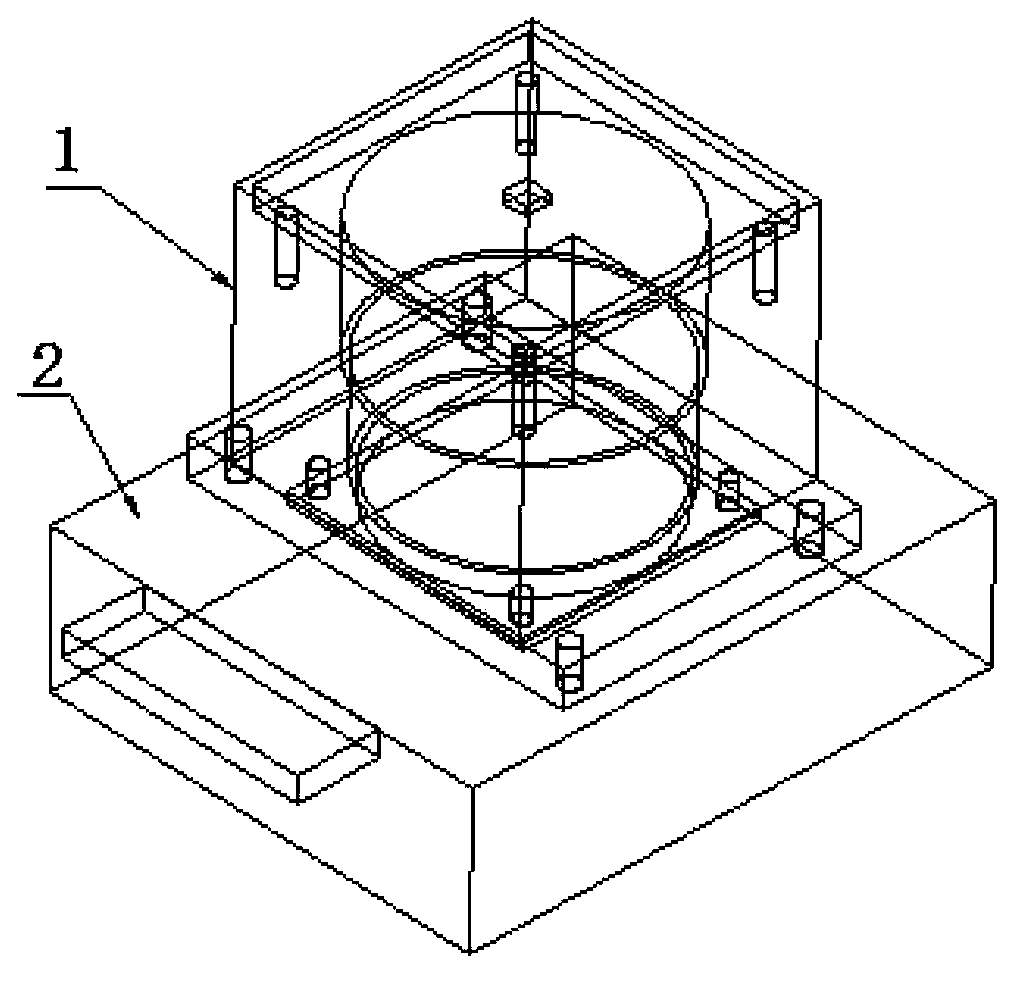

[0021] Embodiment: An image sensor chip test fixture with a test light source, including a test light source 1 and a test fixture 2 , the test light source 1 is fixed on the upper end of the test fixture 2 . The test light source is directly installed on the test fixture, without the push and pull action of the traditional LED surface light source, which saves working time and improves the work efficiency of the operator.

[0022] Wherein, the structure of the test light source 1 is as follows: it includes an LED light source frame 11, an LED lamp bead 12 and at least one uniform light plate 13, and the LED light source frame 11 is a metal structure frame of the LED light source (socket LED frame). Both the LED lamp bead 12 and the light uniform plate 13 are located in the LED light source frame 11, the LED lamp bead 12 is located in the inner top center of the LED light source frame 11, and the light uniform plate 13 is located in the LED light source frame 11. 12, the adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com