Glutathione sensor, preparation method thereof and application thereof in capillary electrophoresis amperometric detection

A glutathione and sensor technology, applied in the field of sensors, can solve the problems of high detection limit and low sensitivity, and achieve the effects of fast response speed, high sensitivity and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

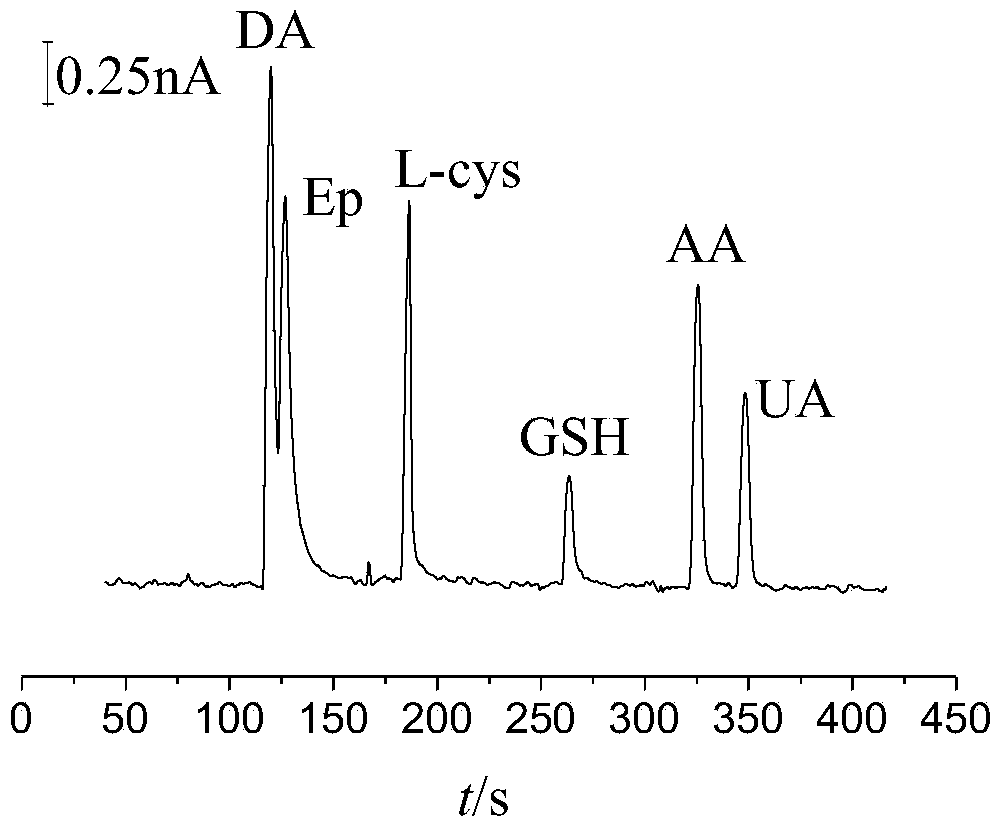

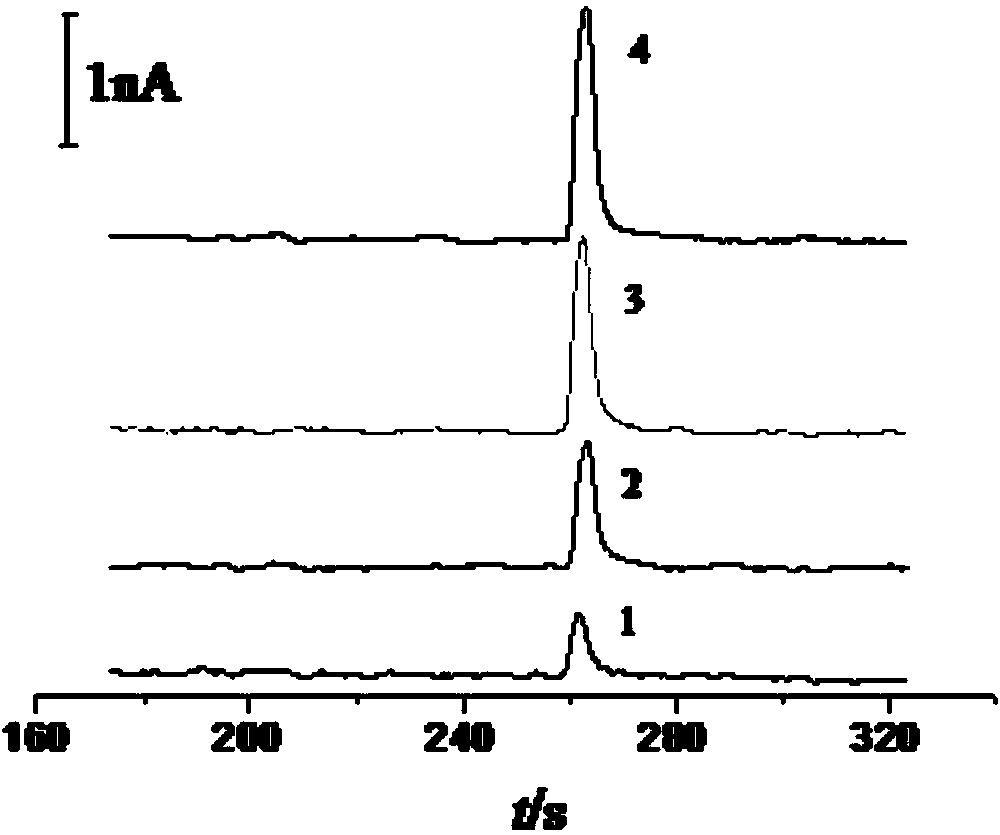

[0024] Embodiment 1 Preparation of glutathione sensor

[0025] Before chemical modification, the surface of the carbon fiber electrode must be cleaned. The specific method is to carefully polish it on metallographic sandpaper to make the surface of the electrode smooth, and then ultrasonically in secondary water, ethanol, and secondary water for 5 minutes each. Let dry at room temperature. Before each test, the graphene oxide solution was ultrasonically dispersed in an ultrasonic cleaner for 30 minutes. In order to prepare graphene oxide-modified carbon fiber electrodes, we immersed the cross-section of the carbon fiber electrodes in the graphene oxide solution for 15 seconds. Avoid immersing the carbon fiber electrodes in the graphene oxide solution too deeply, so as not to expand the active surface of the electrode. Take out the electrode and let it dry at room temperature. Then put the dried graphene oxide modified electrode into 0.1mol / L phosphate buffer solution contain...

Embodiment 2

[0027]Before chemical modification, the surface of the carbon fiber electrode must be cleaned. The specific method is to carefully polish it on metallographic sandpaper to make the surface of the electrode smooth, and then ultrasonically in the secondary water, ethanol, and secondary water for 3 minutes. Let dry at room temperature. Before each test, the graphene oxide solution was ultrasonically dispersed in an ultrasonic cleaner for 30 minutes. In order to prepare graphene oxide-modified carbon fiber electrodes, we immersed the cross-section of the carbon fiber electrodes in the graphene oxide solution for 20 s. Avoid immersing the carbon fiber electrodes in the graphene oxide solution too deeply, so as not to expand the active surface of the electrode. Take out the electrode and let it dry at room temperature. Then put the dried graphene oxide modified electrode into 0.1mol / L phosphate buffer solution containing pH 7.0, and electrodeposit it at -1.1V for 200s. After takin...

Embodiment 3

[0029] Before chemical modification, the surface of the carbon fiber electrode must be cleaned. The specific method is to carefully polish it on metallographic sandpaper to make the surface of the electrode smooth, and then ultrasonically in the secondary water, ethanol, and secondary water for 3 minutes. Let dry at room temperature. Before each test, the graphene oxide solution was ultrasonically dispersed in an ultrasonic cleaner for 20 minutes. In order to prepare graphene oxide-modified carbon fiber electrodes, we immersed the cross-section of the carbon fiber electrodes in the graphene oxide solution for 18s. Avoid immersing the carbon fiber electrodes in the graphene oxide solution too deeply, so as not to expand the active surface of the electrode. Take out the electrode and let it dry at room temperature. Then put the dried graphene oxide modified electrode into 0.1mol / L phosphate buffer solution containing pH 7.0, and electrodeposit it at -0.8V for 300s. After takin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com