Turbine mechanical fly ball laser sealing welding seam inspection method

A sealing welding and steam turbine technology, which is applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems such as the inability to meet the inspection requirements of mechanical flyweight laser sealing welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as Figure 1-Figure 3 As shown, the steam turbine mechanical flyweight laser seal welding seam inspection method described in this embodiment is carried out according to the following steps:

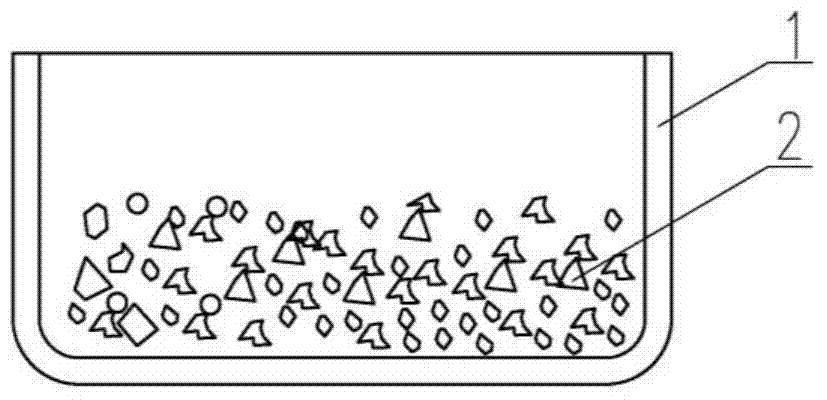

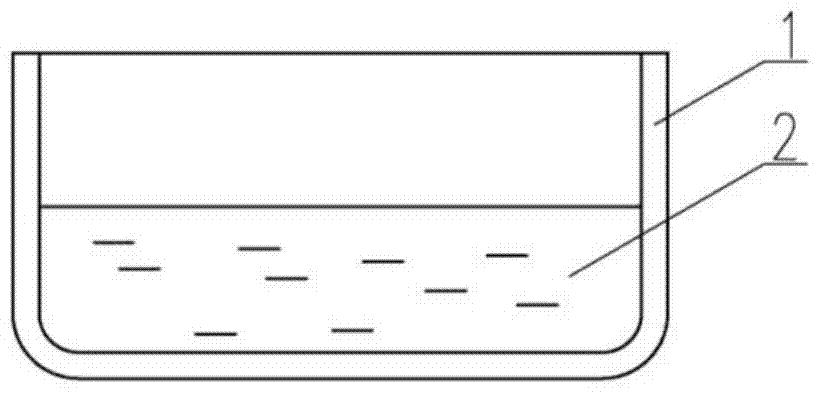

[0021] a) Put the solid wax solvent 2 into container 1 and melt it into a liquid solvent, keeping the temperature of the liquid wax solvent at 72°C

[0022] -80°C.

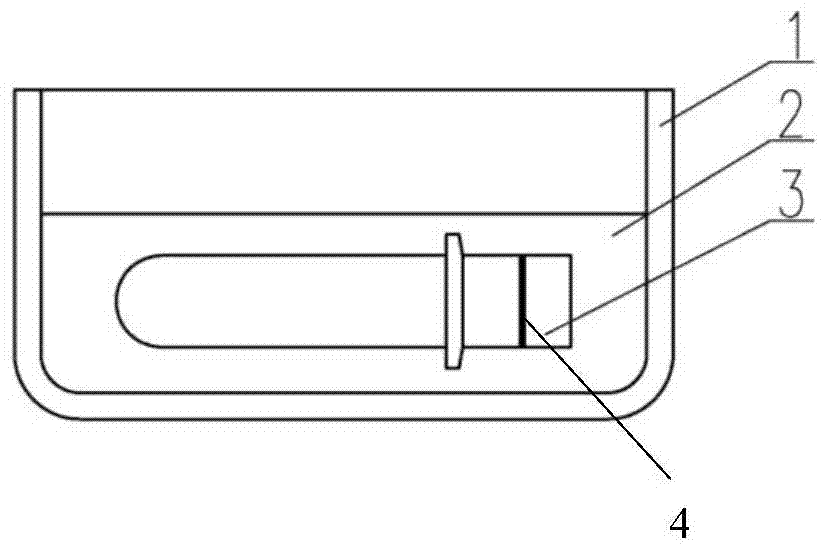

[0023] b) Completely immerse the mechanical fly hammer 3 that has completed seal welding in the liquid solvent, and the immersion time is not less than 3 minutes;

[0024] c) Check whether there are air bubbles overflowing at the 4 seams of mechanical fly hammer seal welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com