Tooth engagement transmission part applied to precise mechanical structure

A technology of precision machinery and transmission components, applied in mechanical equipment, components with teeth, belt/chain/gear, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

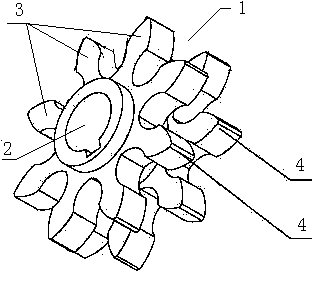

[0022] see figure 2 , the tooth meshing transmission part applied to the precision mechanical structure of this embodiment includes a circular thin sheet body 1, a rotating shaft 2 passing through the center of the body 1, and the outer edge of the circumference of the body 1 is formed with axially divided There are two layers of meshing teeth groups 3, and the tooth shapes and tooth pitches of the meshing teeth 4 in the two layers of meshing teeth groups 3 are the same, and the meshing teeth 4 adjacent to each other are staggered in the circumferential direction, thus forming Staggered plate gears.

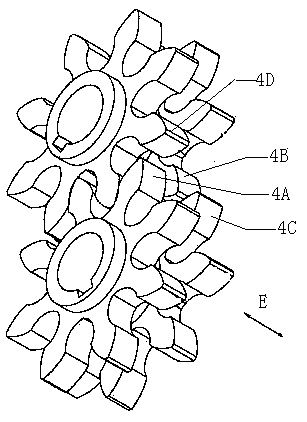

[0023] see image 3 , showing a gear pair consisting of two staggered plate gears as described above. In both gears, the toothing 4 on the corresponding level meshes with each other in the usual manner. And between the layers, since the adjacent meshing teeth 4 are staggered from each other along the circumferential direction, a first meshing tooth 4A of the driving gear and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com