A highly fuel-efficient engine

A technology of engine and transmission mechanism, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of reducing gas volume compression ratio, only proper delay, low fuel utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

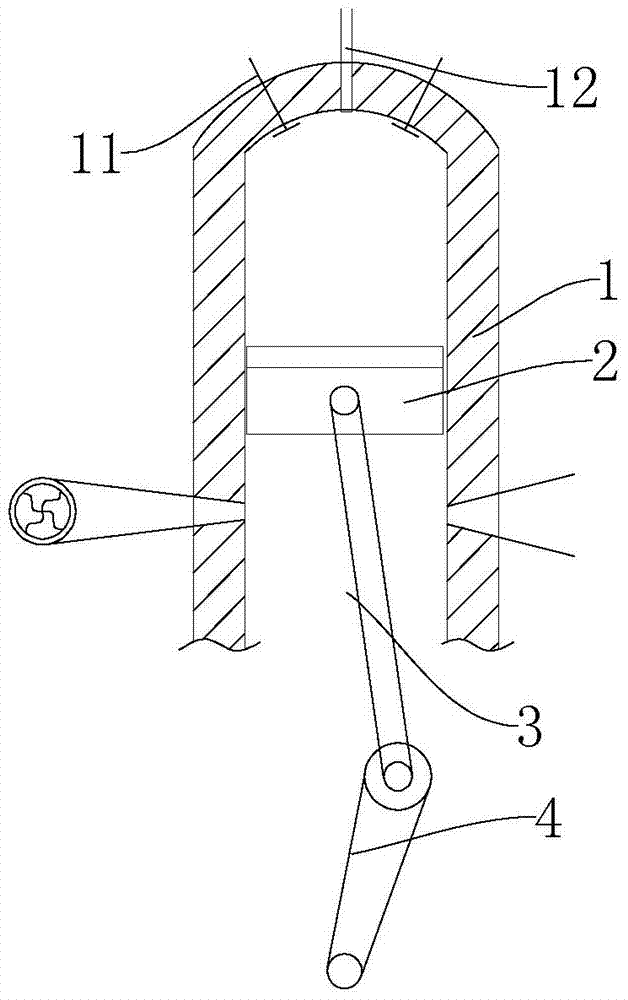

[0021] Such as figure 1 Shown is a prior art engine, including a cylinder 1, a main piston 2 reciprocating in the cylinder 1, a connecting rod 3 connected to the main piston 2, a crankshaft 4 driven by the connecting rod 3, and a spark plug 11 at the top of the cylinder 1 and the fuel injector 12, when the main piston 2 moves to the top in the cylinder 1, the fuel injector 12 injects fuel, the spark plug 11 ignites and explodes, and then pushes the piston 2 to move downward in the cylinder 1, and then drives the crankshaft 4 to move, when the piston 2 At the top dead center, the compression ratio of piston 2 in cylinder 1 is the highest (compression ratio is the ratio of the total volume of the cylinder to the volume of the combustion chamber), at this time, the ignition of the spark plug 11 can release the maximum explosive energy to become the power output of the engine , but while maintaining a high compression ratio, the length of the moment arm between the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com