Air pre-compressed feeding system of aerating engine

An air supply system and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as affecting energy conversion rate, high gas compression ratio, inability to obtain, etc., to improve energy conversion efficiency and high gas compression. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

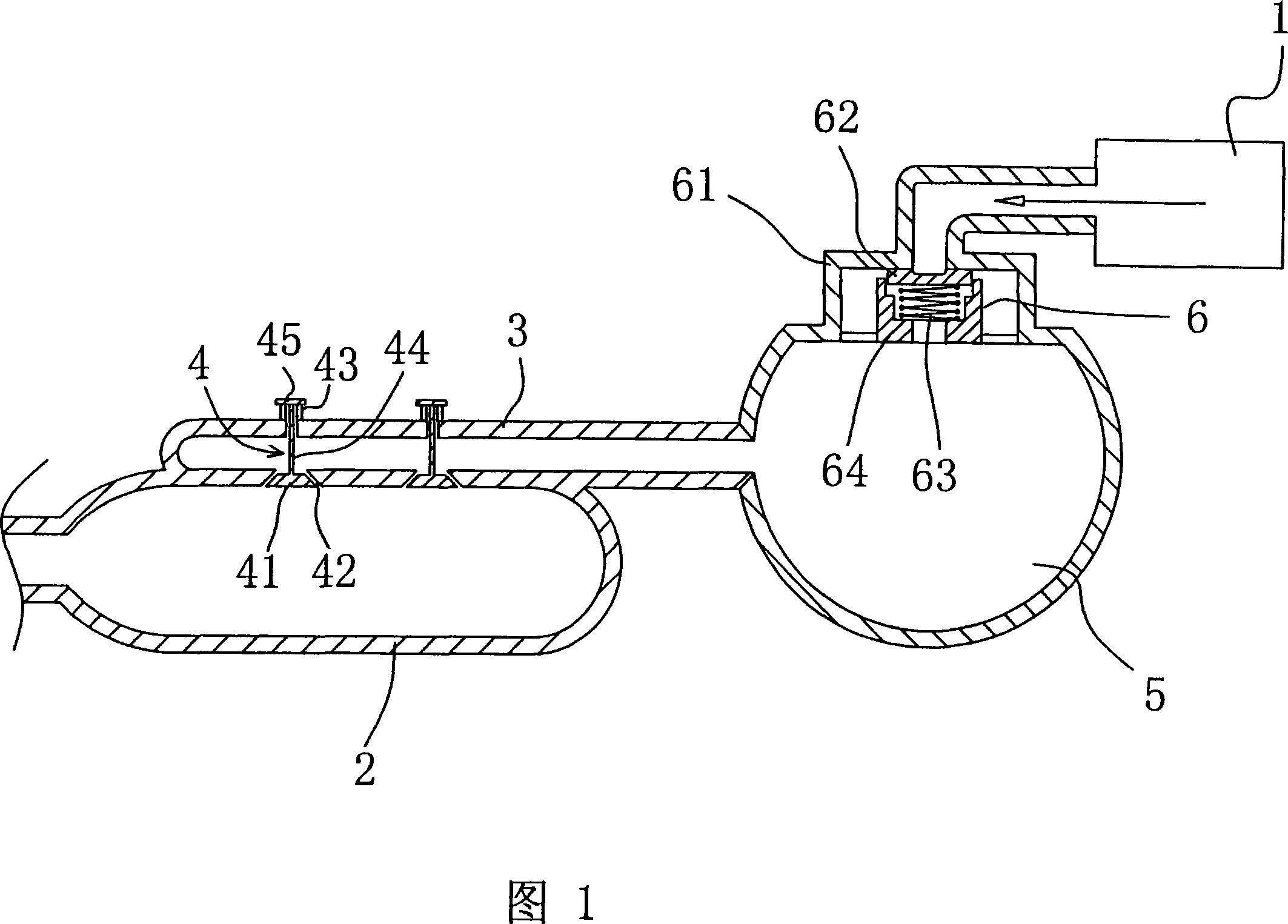

[0009] See shown in Figure 1, the technical scheme of the present invention is: it comprises air pressure generating device 1 and combustion chamber 2, and air pressure generating device 1 refers to the device that can produce or promote gas pressure, is provided with air inlet 3 on combustion chamber 2 outer walls At least one charging valve 4 is provided between the combustion chamber 2 and the intake passage 3, and an air storage chamber 5 is also provided between the air pressure generating device 1 and the intake passage 3, and the air pressure generating device 1 communicates with the storage chamber through a one-way valve 6 The air chamber 5 communicates.

[0010] The inflation valve 4 includes a valve 41, a valve seat 42, and a valve spring 43. The head of the valve 41 is conical and cooperates with the valve seat 42 provided on the outer wall of the combustion chamber 2. The valve stem 44 is provided with a valve spring seat 45 , The valve spring seat 45 bottom is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com