Disc-shaped internal combustion engine

An internal combustion engine, disc-shaped technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of poor running smoothness, poor stability, complex structure, etc., to achieve increased working stability, simple and reliable structure , the effect of easy power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

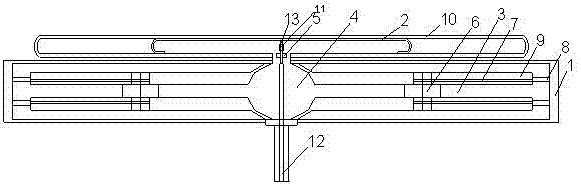

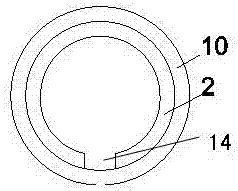

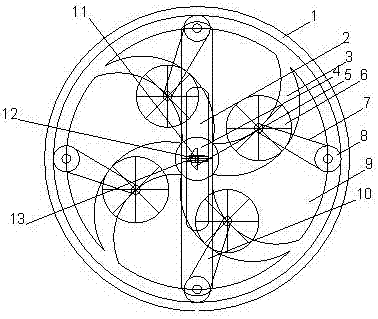

[0038] A kind of disc-shaped internal combustion engine described in conjunction with accompanying drawing, comprises the casing 1 with exhaust port, and the inside of described casing 1 is provided with disk 9, and the top of casing 1 is provided with fixed cylinder liner 10, and fixed cylinder A sliding piston sleeve 2 is arranged inside the sleeve 10;

[0039] Several gas passages 3 are arranged inside the disc 9, and one end of the gas passages 3 converges in the transition chamber 4, and an energy collection device 6 is arranged in the gas passage 3, and the energy collection device 6 is connected to a roller 8 through a transmission device 7, and the roller The side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com