Downhole Infinite Stage CNC Fracturing Sleeve

A fracturing sliding sleeve, infinite stage technology, applied in the direction of wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve unfavorable post-workover operations, high construction risks, and heavy drilling workload and other issues, to achieve the effect of reducing labor intensity and construction risk, reducing secondary pollution, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

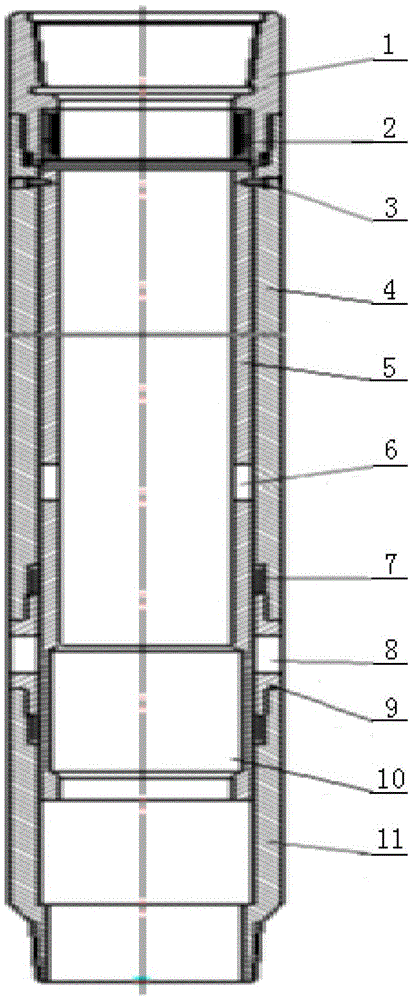

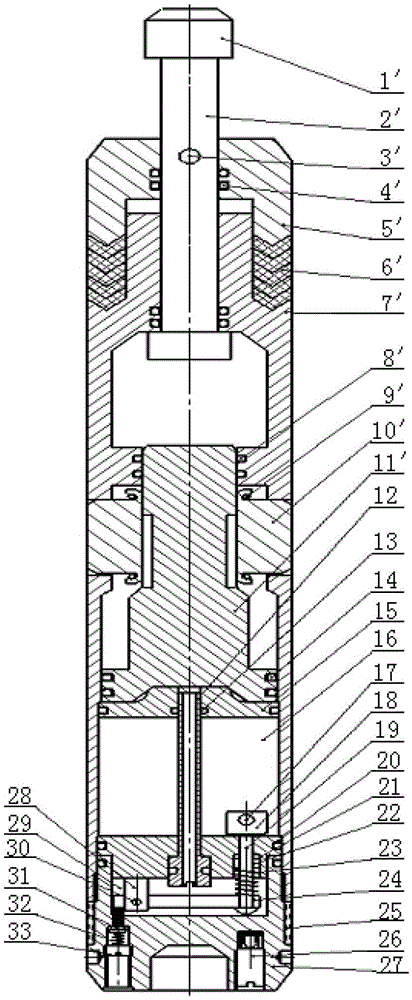

[0020] The downhole infinite-stage numerical control fracturing sleeve includes three parts: numerical control fracturing sleeve, numerical control plug and unblocking.

[0021] The numerical control fracturing sliding sleeve is composed of an upper joint 1, a layer ID card 2, a shear pin 3, a connecting sleeve 4, an inner sliding sleeve 5, a V-shaped seal 7, a body 9 and a lower joint 11. Both ends of the connecting sleeve 4 are threadedly connected to the upper joint 1 and the body 9 respectively. Both ends of the body 9 are provided with V-shaped seals 7, four radial fracturing ports 8 are evenly provided on the middle wall of the cylinder, and the lower end is threadedly connected with a lower joint 11 provided with inner wall steps. The connecting sleeve 4 is connected to the inner sliding sleeve 5 through the shear pin 3. The top of the inner sliding sleeve 5 is provided with a layer ID card 2, the lower end is provided with a switch slot 10, and the middle wall is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com