Slide switch device

A technology of sliding sleeve switch and sliding sleeve, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of increasing construction period and risk, and achieve unlimited fracturing stages and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

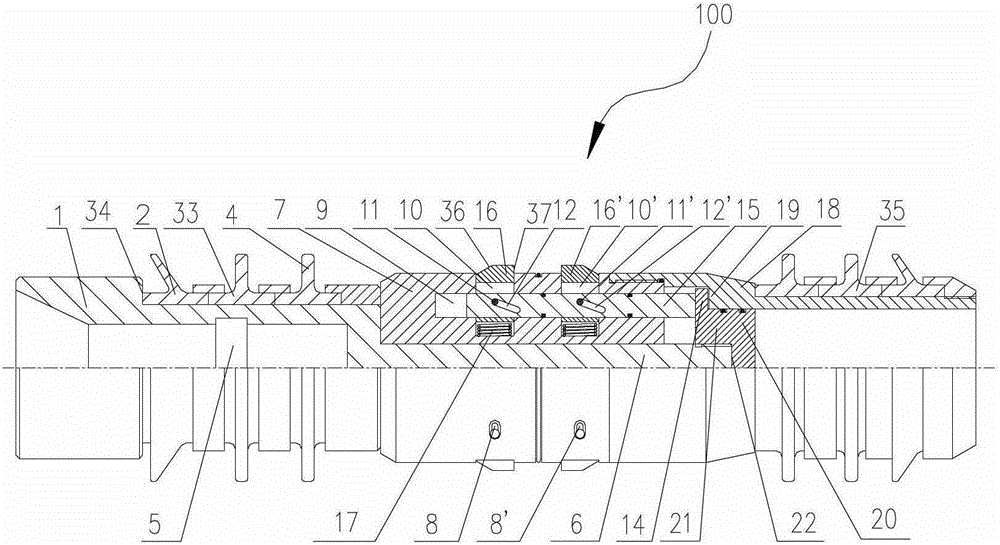

[0030] figure 1 A sliding switch device 100 according to the invention is schematically shown. The sliding switch device 100 includes: a cylindrical body 1 , which is in the shape of a stepped shaft and whose diameter gradually decreases toward the first end 6 . On the circumferential side wall of the first end 6 of the main body 1, there are provided circumferentially elongated first guide nail grooves 8, 8' penetrating the side wall, which are used to guide guide nails together with other structures described below 11, 11' movement.

[0031] The sliding switch device 100 also includes a locking block assembly mounted on the first end 6 of the body 1 . The lock block assembly includes a housing 7 slidably mounted on the first end 6 of the body 1 . In a preferred embodiment, the housing 7 is ring-shaped and sleeved on the first end 6 of the body 1 in a sliding manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com