Fracturing short section and fracturing pipe string including fracturing short section

A sub-joint and fracturing technology, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high cost, affecting the running of downhole tools, and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

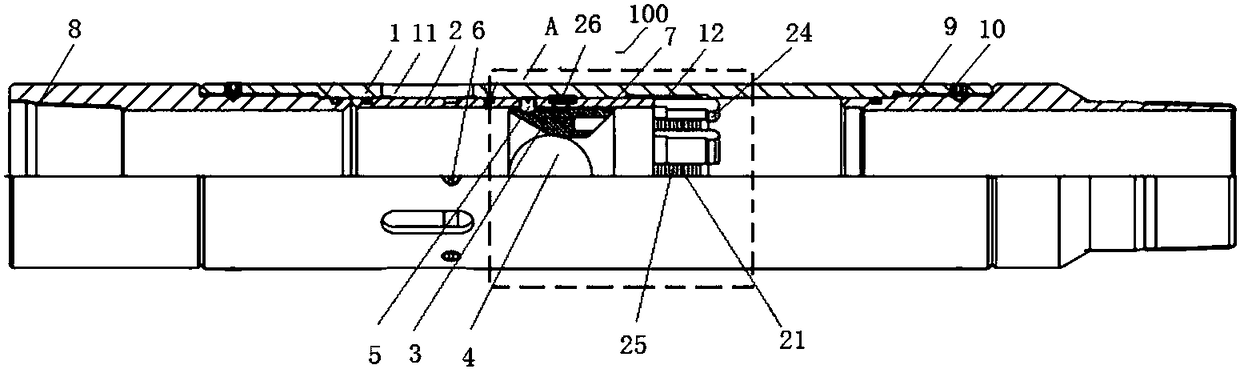

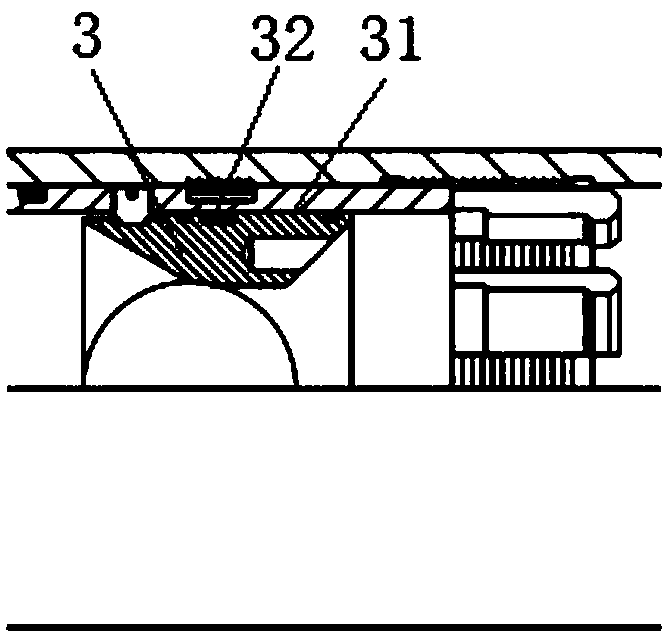

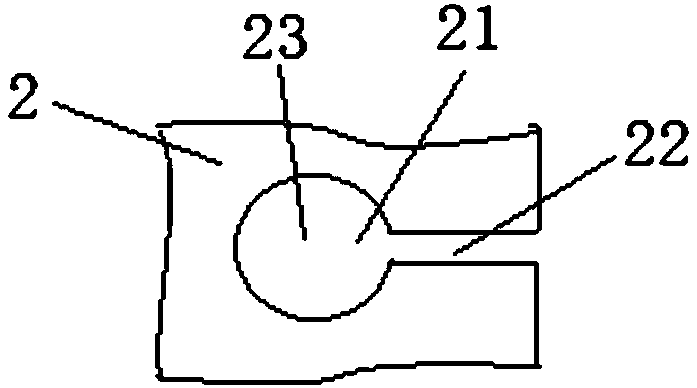

[0029] figure 1 A frac sub 100 according to the present invention is shown. The fracturing sub 100 includes a body 1 , an inner sliding sleeve 2 , a ball seat 3 and a ball 4 . Wherein, the main body 1 is cylindrical, and a circulation hole 11 is arranged on the wall thereof for transporting fracturing fluid to the outside. The inner sliding sleeve 2 is arranged in the inner cavity of the body 1 and is used to block the circulation hole 11 in an initial state. Under the action of the second hydraulic pressure, the inner sliding sleeve 2 can move relative to the main body 1 to expose the circulation hole 11. In this case, the fracturing operation can be performed. The ball seat 3 is arranged in the inner cavity of the inner sliding sleeve 2, and is used for cooperating with the dropped ball 4 to block the inner channel of the inner sliding sleeve 2, thereby realizing press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com