Two-way drive roving frame

A two-way transmission and roving frame technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of rising equipment manufacturing and maintenance costs, increasing equipment failure risk index, small lifting drive shaft Torque and other problems, to achieve the effect of improving the output and production efficiency of a single machine, the increase of equipment manufacturing cost is small, and the number of spindles is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The two-way transmission roving frame of the present invention will be described in detail below in conjunction with the accompanying drawings.

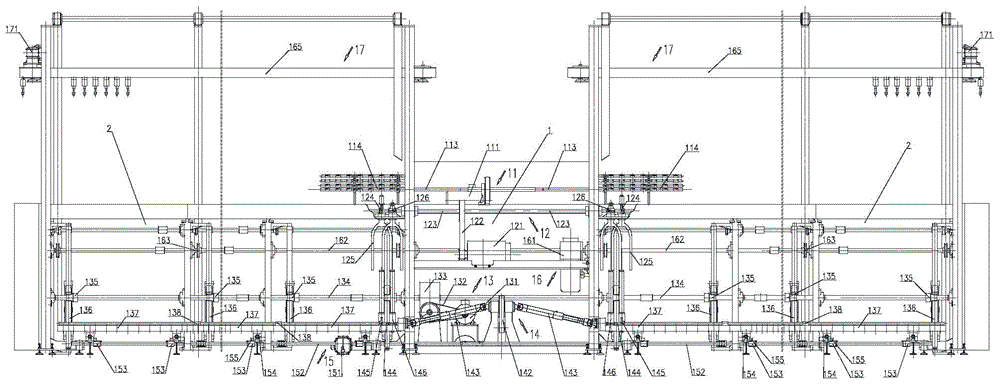

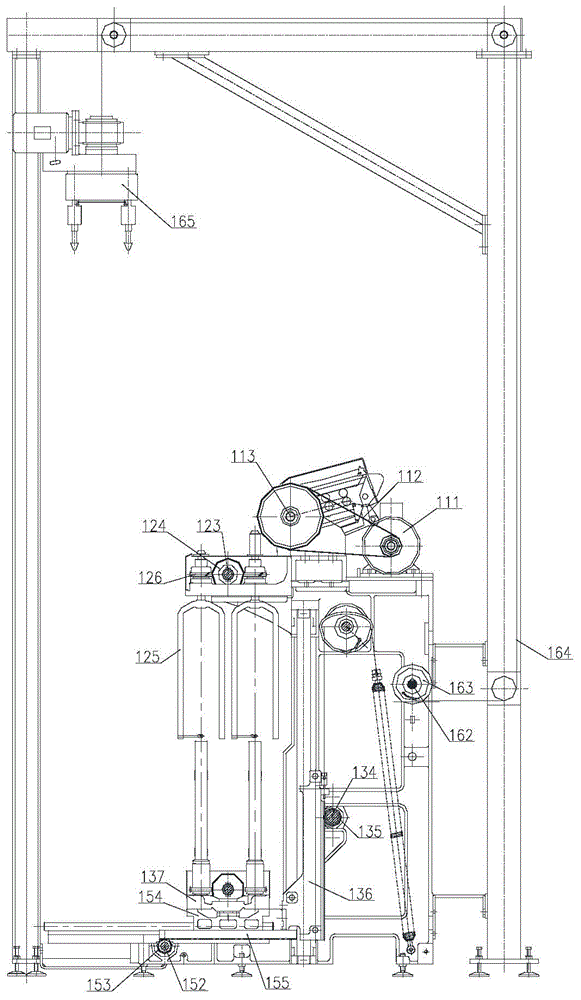

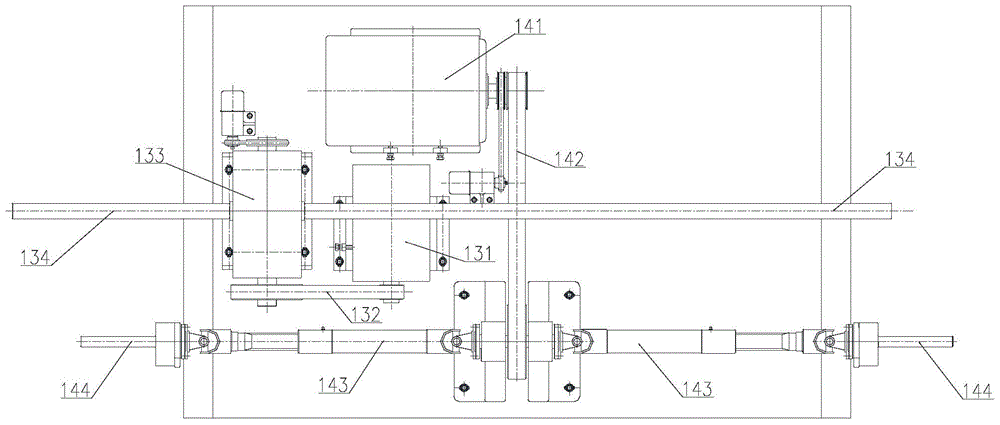

[0029] Such as figure 1 As shown, the two-way transmission roving frame mechanism of the present invention includes a headstock 1, a vehicle body 2, and a power output part. The power output part is arranged inside the headstock 1, and the power output of the roving frame is transmitted from the headstock 1 to the body 2 located on the left and right sides thereof.

[0030] The power input part of the above-mentioned roving frame adopts a power source and a set of power control system; the above-mentioned left section body and right section body are preferably symmetrically distributed on the left and right sides of the headstock 1 .

[0031] For ease of understanding, the attached Figure 1-3 , taking the automatic doffing roving frame as an example, the four major motion components required for the spinning process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com