Structure-optimized bobbin suction auxiliary system

An auxiliary system and bobbin technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as joint failure and low machine production efficiency, so as to improve production efficiency and save consumption , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

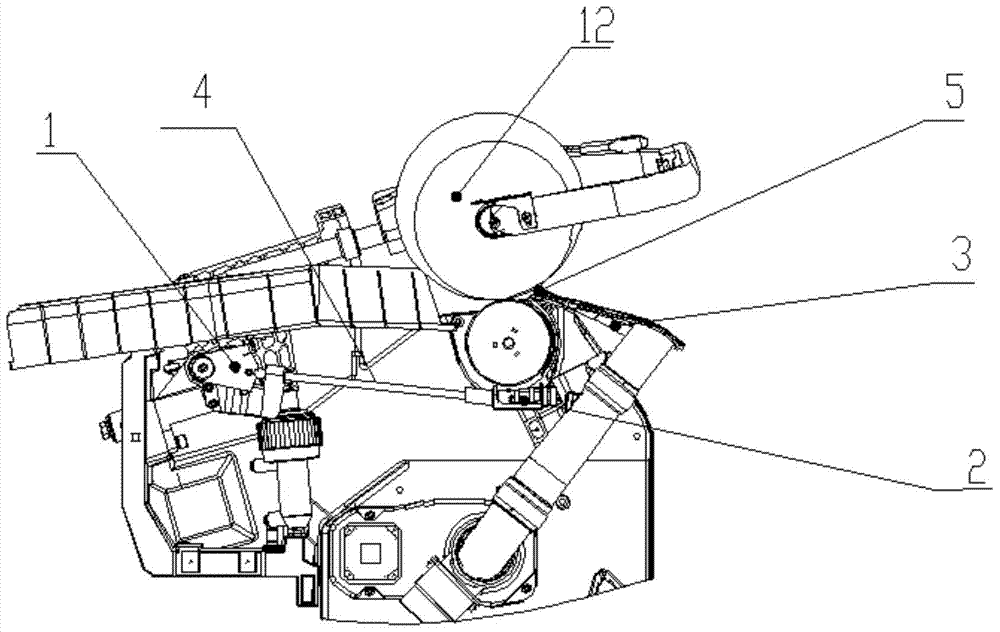

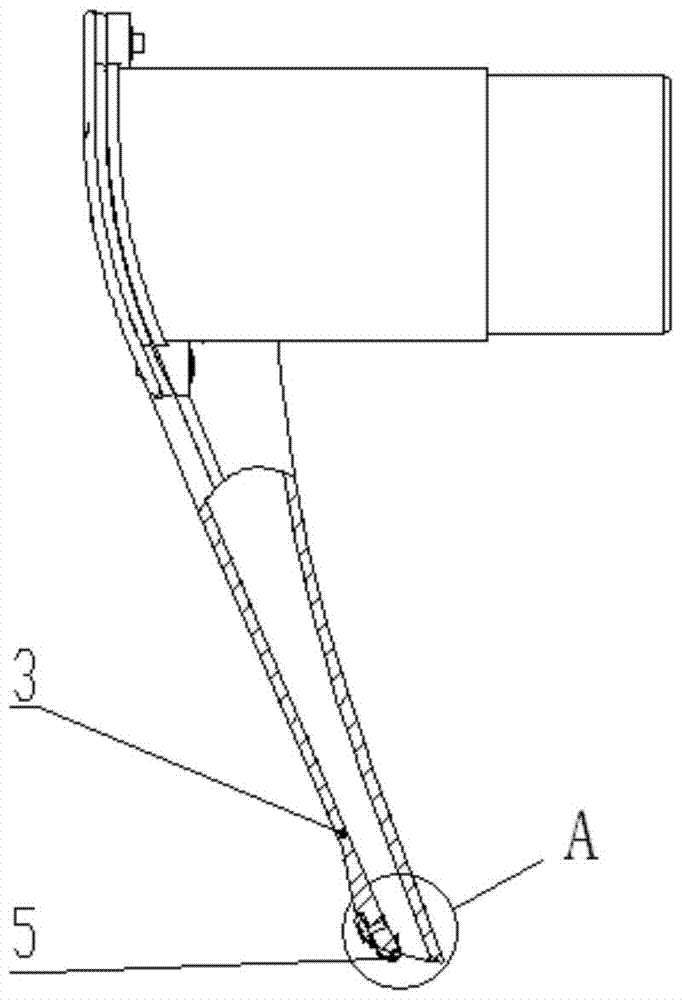

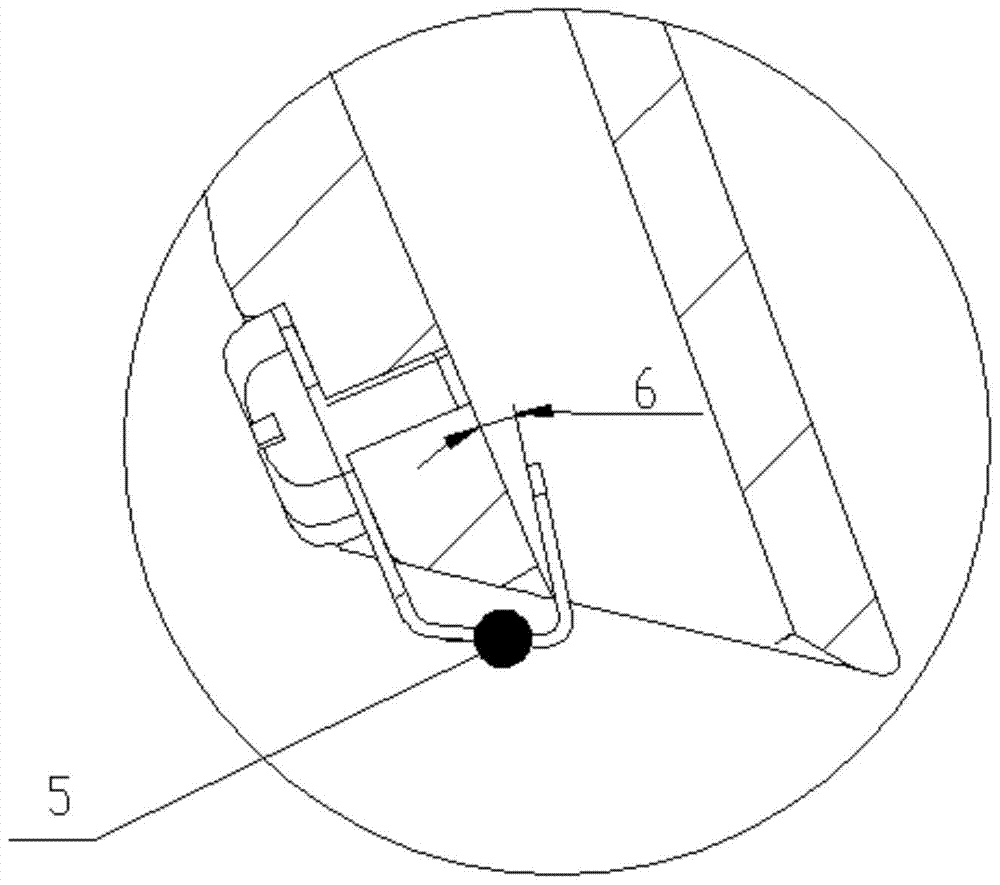

[0018] Embodiment: A structurally optimized bobbin suction auxiliary system, including a bobbin suction nozzle 3 positioning cam 1 coaxial with the bobbin cradle, a driven push rod 4, a bobbin suction nozzle positioning sensor 2, and a bobbin suction nozzle 3 and the driving device, one end of the driven push rod 4 is tightly against the outer curved surface of the cam circumference, and the other end is fixed with a package yarn suction nozzle positioning sensor 2, and the driven push rod 4 can slide along its length direction to position the package yarn suction nozzle The sensor 2 is close to or far away from the package suction nozzle 3, and the driving device drives the package yarn suction nozzle 3 to swing. A sawtooth bent plate 5 with a sawtooth structure on the surface. The sawtooth bent plate extends a set distance from the opening of the mouth of the package suction nozzle 3 to the inside of the package suction nozzle 3. The inner wall of the opening forms an includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com