High-temperature stator rubber material and preparation method thereof

A rubber material and stator technology, which is applied in the field of high temperature stator rubber material and its preparation, can solve the problems of short drilling service life, easy occurrence of block drop and delamination, etc., and achieve long service life, excellent bonding strength and stable process operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

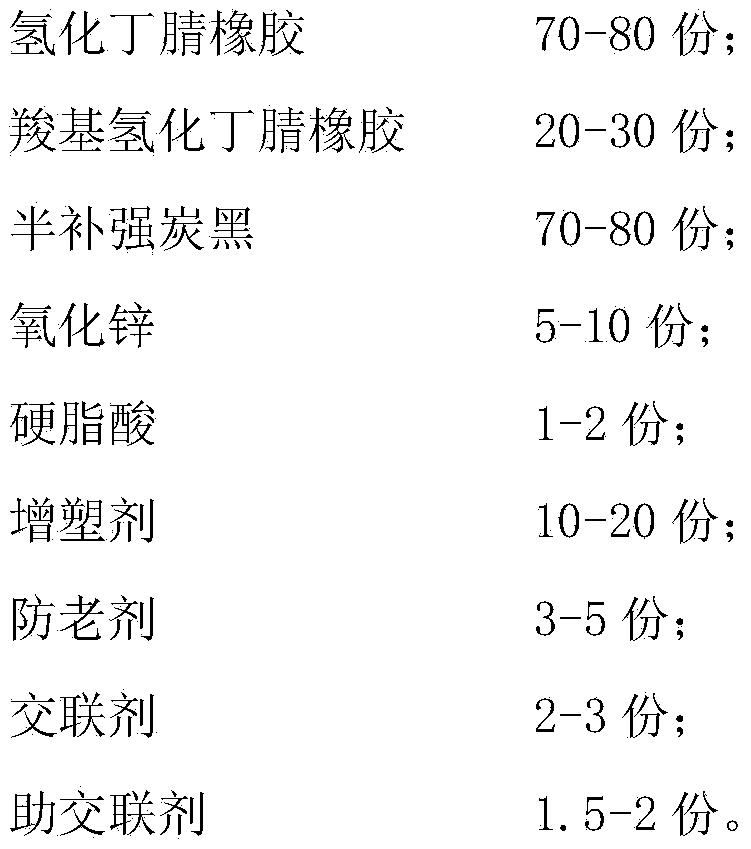

[0030] Table 1

[0031] serial number

components

Dosage (number of parts by mass)

1

LANXESS Hydrogenated Nitrile 3904

70

2

LANXESS carboxylated hydrogenated nitrile rubber XT8889

30

3

Cabot Semi-Reinforced Carbon Black N550

70

4

5

5

1

6

Plasticizer TP-95

10

7

Antiager D

2

8

Antiaging agent 4010

3

9

Cross-linking agent DCP

2

10

Crosslinking Auxiliary TAIC

2

[0032] Above-mentioned table 1 is each component of the material of the present embodiment and the consumption situation of each component, wherein:

[0033] 1. Hydrogenated nitrile is 3904 hydrogenated nitrile produced by Lanxess, Germany. The hydrogenated nitrile rubber has an acrylonitrile content of 39%, a Mooney viscosity of 39, and a residual double bond content of ≤0.9. It has better oil resistance and more Low Mooney vi...

Embodiment 2

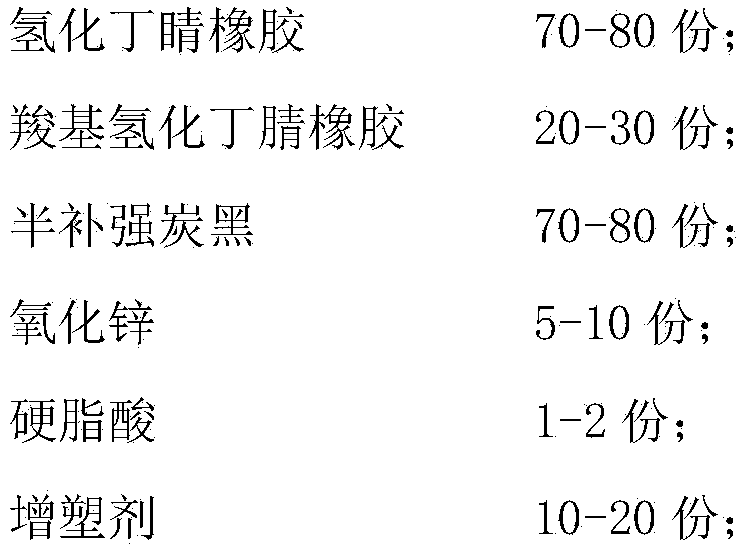

[0053] Table 2

[0054] serial number

components

Dosage (parts by mass)

1

LANXESS Hydrogenated Nitrile 3904

80

2

LANXESS carboxylated hydrogenated nitrile rubber XT8889

20

3

Semi-reinforcing carbon black N550

80

4

10

5

2

6

Plasticizer TP-95

10

7

Antiaging agent RD

2

8

Antiaging agent 4010NA

2

[0055] 9

Cross-linking agent DCP

3

10

Crosslinking Auxiliary TAIC

1.5

[0056] Above-mentioned table 2 is each component of the material of the present embodiment and the consumption situation of each component, wherein:

[0057] 1. Hydrogenated nitrile is 3904 hydrogenated nitrile produced by Lanxess, Germany. The content of acrylonitrile is 39%, the Mooney viscosity is 39, and the residual double bond content is ≤0.9. It has better oil resistance and lower Mooney viscosity. More ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com