Preparation method of porous carbon and product thereof

A technology of porous carbon and biomass carbon source, applied in nano-carbon, hybrid capacitor electrodes, etc., can solve the problems of difficult to increase specific surface area, a large amount of acid and alkali, complicated steps, etc., and achieve adjustable and renewable mesoporous micropore ratio. Cost, effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

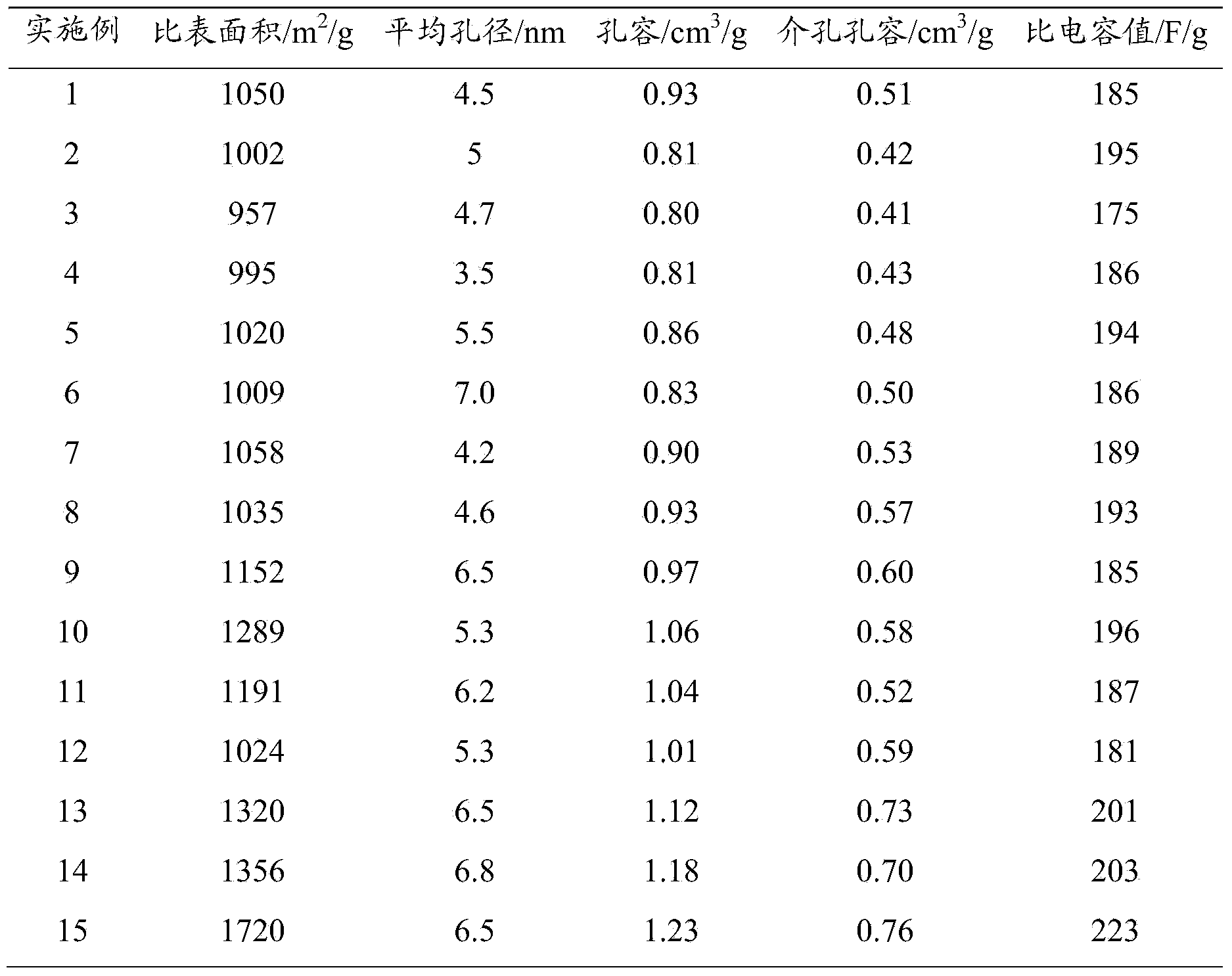

[0030] 2g fructose, 10mg potassium polystyrene sulfonate and 30ml water were added to a 100ml hydrothermal kettle, and the reaction was sealed in an oven at 180°C for 12h. The material was taken out, washed and dried, and then calcined in an air atmosphere at 800° C. for 1 h to obtain porous carbon. Pass N 2 In the adsorption and desorption test, the particle size, specific surface area and average pore diameter data of the obtained porous carbon are shown in Table 2.

Embodiment 2~15

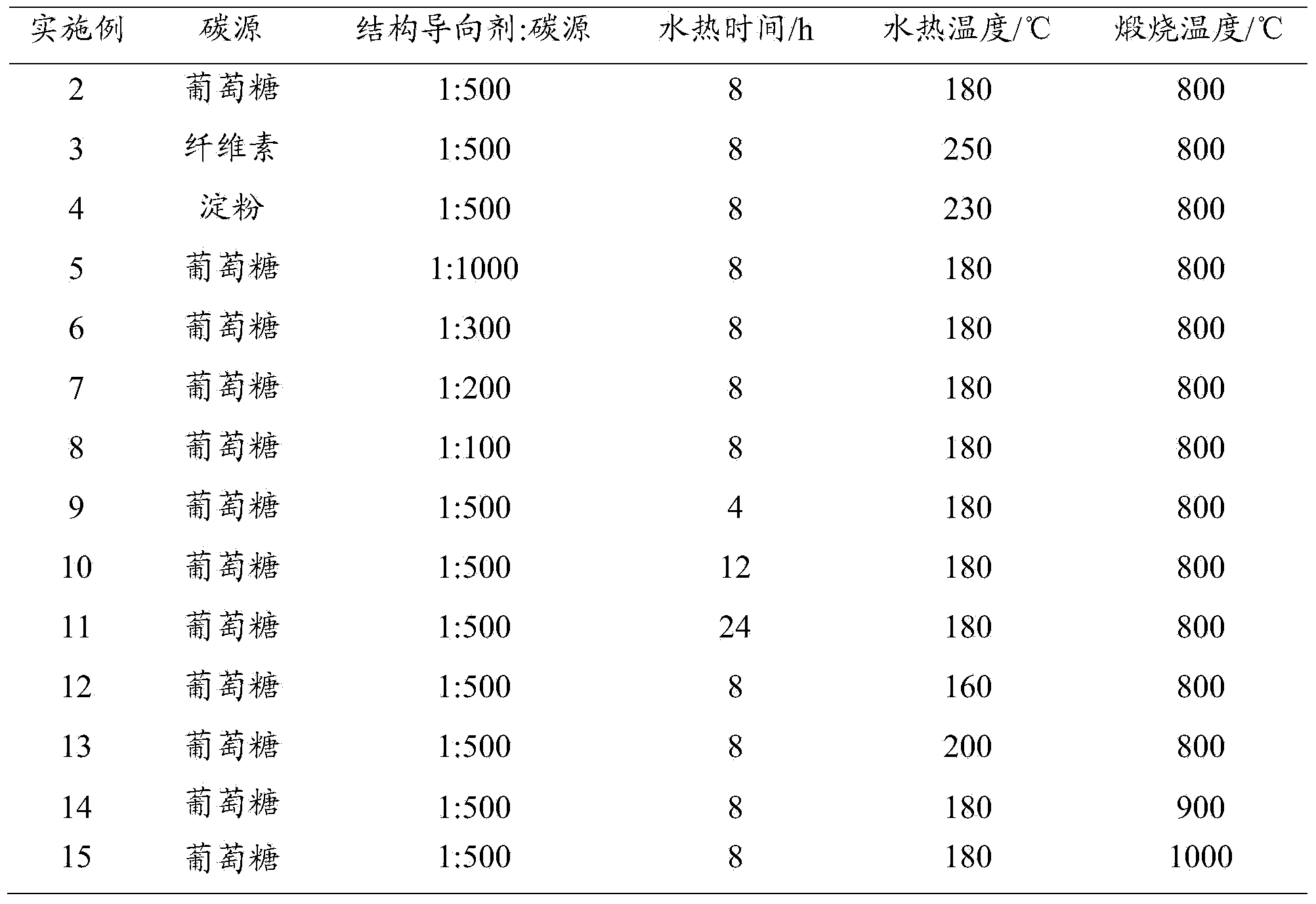

[0032] Add 6g of different carbon sources, polyvinylidene dimethyl ammonium chloride and 50ml of water in a certain mass ratio with the carbon source into a 100ml hydrothermal kettle, and take it out after a period of hydrothermal reaction in an oven at a certain temperature After washing and drying, it is calcined in air atmosphere at a certain temperature for 1 hour to obtain porous carbon. The types, proportions and reaction conditions of the reaction materials are shown in Table 1. Pass N 2 In the adsorption and desorption experiment, the particle size, specific surface area and average pore diameter data of the obtained porous carbon are shown in Table 2.

[0033] Table 1

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com