PVC tablecloth and manufacturing method thereof

A production method and tablecloth technology, applied to chemical instruments and methods, tablecloths, lamination, etc., can solve the problems of not being durable enough, not environmentally friendly, easy to have peculiar smell, etc., to reduce production costs, reduce waste gas emissions, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

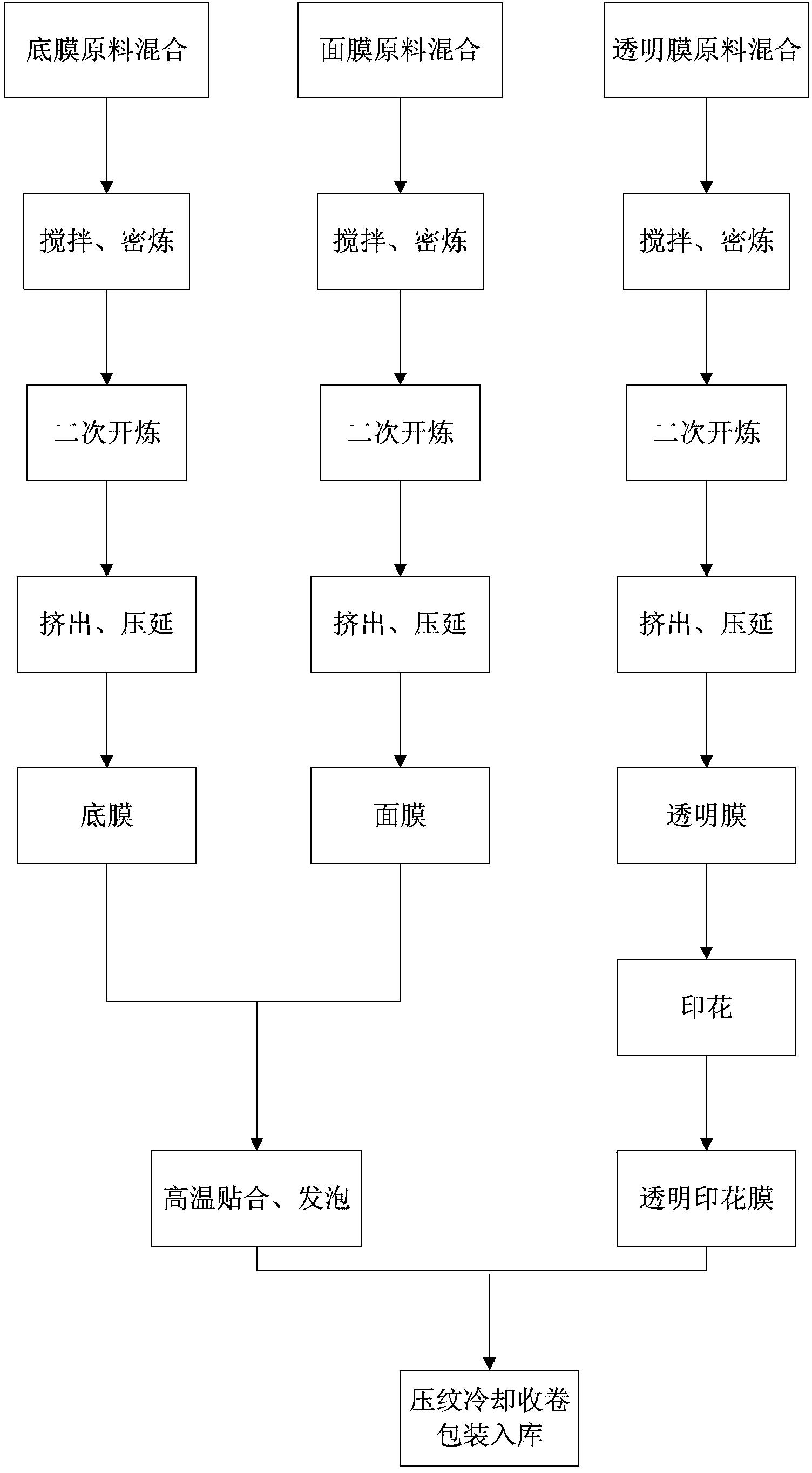

Method used

Image

Examples

Embodiment Construction

[0019] The PVC tablecloth of the present invention includes a base film, a mask and a transparent film, wherein the base film includes the following components in weight percentage: 50% to 54% of PVC, 24% to 28% of plasticizer, heat stable 1% to 2% of additives, 1% to 2% of ADC foaming agents, 0.1% to 0.5% of lubricants, 1% to 2% of functional additives, 13% to 18% of fillers, and 1% to 2% of pigments; The mask includes the following components by weight percentage: PVC56%~60%, plasticizer 27%~31%, heat stabilizer 1%~2%, lubricant 0.1%~0.5%, functional additive 1%~2 %, filler 3%~7%, pigment 1%~4%; the transparent film includes the following components by weight: PVC70%~74%, plasticizer 23%~27%, heat stabilizer 1% ~3%, pigment 0.11%~0.6%.

[0020] As a preferred version of this embodiment, the base film includes the following components by weight: PVC 100kg, plasticizer 50kg, heat stabilizer 3kg, ADC foaming agent 2.5kg, lubricant 0.31kg, functional auxiliary agent 3kg, fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com