A kind of nano-nickel-based methanation catalyst and its preparation method and application

A methanation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory activity, agglomeration of active components, small specific surface area, etc., and achieve the preparation time Effects of shortening, promoting dispersion, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 7.8g of nickel nitrate, 51.5g of aluminum nitrate, 1.7g of zirconium oxynitrate, 0.3g of europium nitrate and 15g of urea, 3g of P123, dissolve in 70mL of deionized water and stir evenly, pour the solution into a ceramic evaporating dish, microwave radiation wavelength 12cm , ignited under the condition of a power of 70W / mL solution, collect the remaining powder after combustion, grind and granulate to 60-100 mesh to obtain a nickel-based methanation catalyst. The catalyst composition is: NiO20wt.%, Al 2 o 3 70wt.%, ZrO 2 9wt.%, Eu 2 o 3 1wt.%.

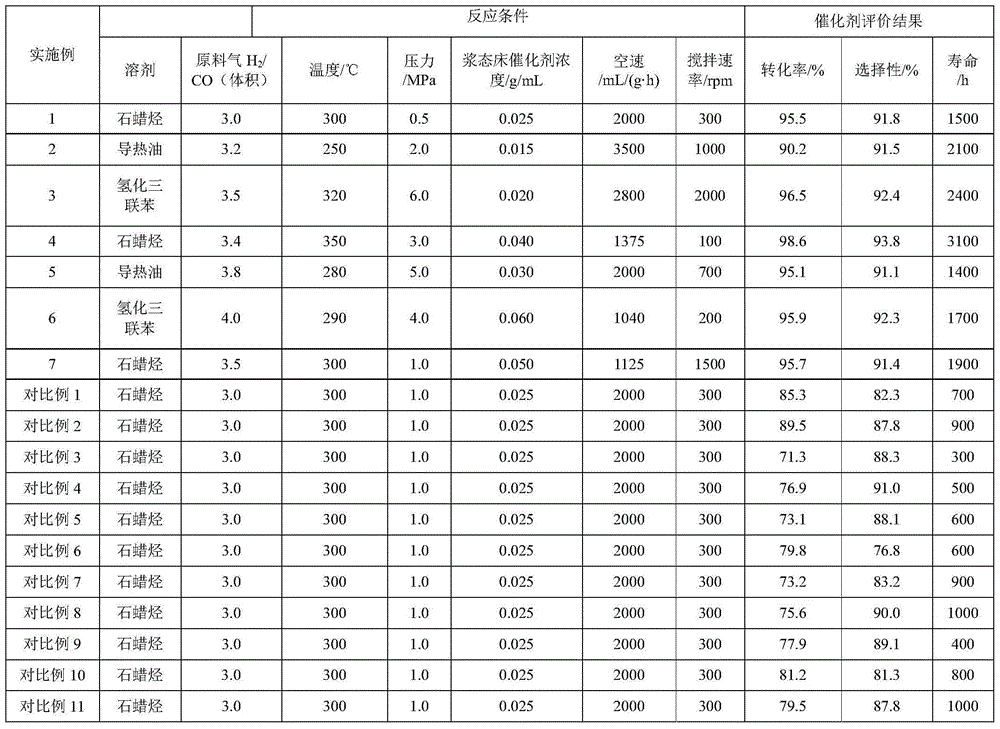

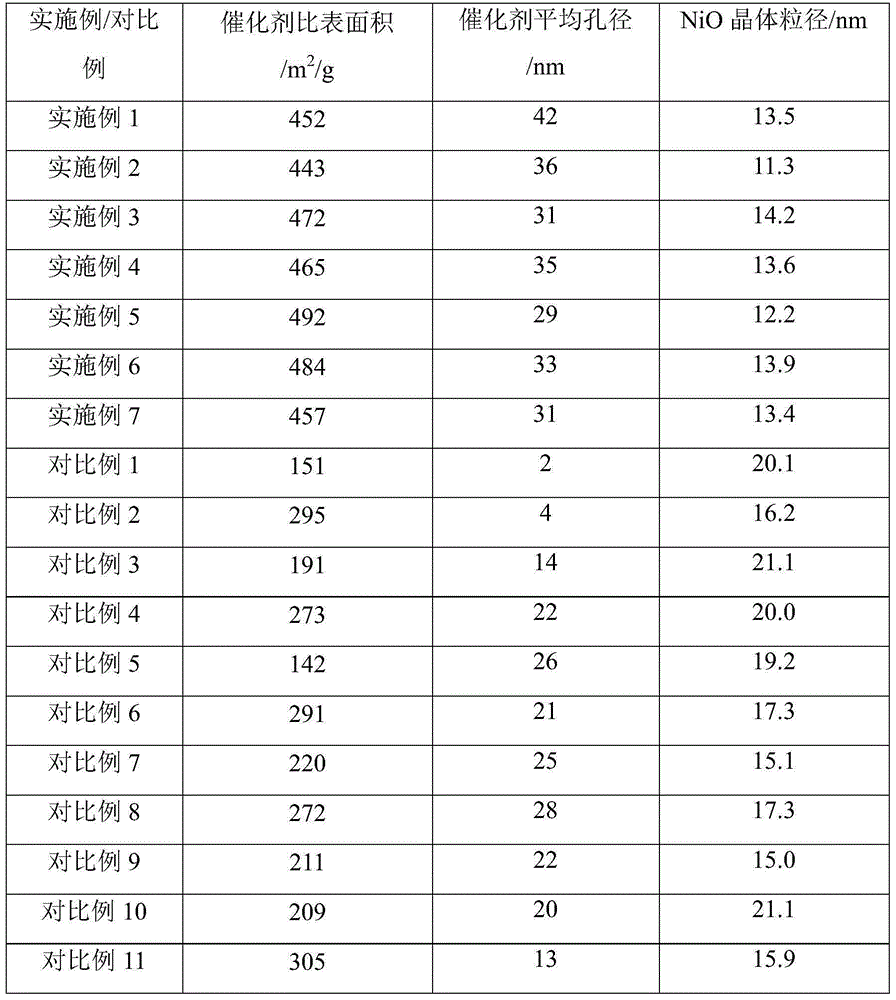

[0032] The catalyst was heated at 15% H 2 with 85%N 2 In the atmosphere, reduce at 400℃ for 10h in a fixed bed with a space velocity of 1000mL / (g·h). See attached table 1 for the activity evaluation conditions and results of the catalyst in the synthesis gas to methane reaction. Specific steps are as follows:

[0033] Inject a certain amount of the above-mentioned catalyst and 120mL of inert liquid medium into a 2...

Embodiment 2

[0035] Weigh 11.7g of nickel nitrate, 47.8g of aluminum nitrate, 1.3g of samarium nitrate, 5g of ethylene glycol and 5g of P123, dissolve in 70mL of deionized water and stir evenly, pour the solution into a ceramic evaporating dish, microwave radiation wavelength 10cm, power 90W / mL Ignite under the condition of the solution, collect the remaining powder after combustion, grind and granulate to 80-120 mesh to obtain the nickel-based methanation catalyst. The catalyst composition is: NiO30wt.%, Al2 o 3 65wt.%, Sm 2 o 3 5wt.%.

[0036] The catalyst was heated in 10% H 2 with 90%N 2 In the atmosphere, reduce at 700℃ for 2h in a fixed bed with a space velocity of 10000mL / (g·h). See attached table 1 for the activity evaluation conditions and results of the catalyst in the synthesis gas to methane reaction. Concrete steps are as shown in embodiment 1.

Embodiment 3

[0038] Weigh 15.6g nickel nitrate, 18.4g aluminum nitrate, 7.4g zirconium oxynitrate, 0.2g holmium nitrate, 7g glycine, 3gP123, dissolve in 100mL deionized water and stir evenly, pour the solution into a ceramic evaporating dish, microwave radiation wavelength 15cm , ignited under the condition of a power of 50W / mL solution, collect the remaining powder after combustion, grind and granulate to 100-140 mesh to obtain a nickel-based methanation catalyst. The catalyst composition is: NiO35wt.%, Al 2 o 3 25wt.%, ZrO 2 39wt.%, Ho 2 o 3 1wt.%.

[0039] The catalyst was heated at 5% H 2 with 95%N 2 In the atmosphere, reduce at 500℃ for 5h in a fixed bed with a space velocity of 2500mL / (g·h). See attached table 1 for the activity evaluation conditions and results of the catalyst in the synthesis gas to methane reaction. Concrete steps are as shown in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com