Motor and twin-roller compressor with the motor

A stator and rotor technology, applied in the field of double-roller compressors, can solve the problems of large consumption of raw materials, high cost, increased moment of inertia, etc., and achieve the effects of saving material costs, improving production efficiency, and enhancing heat dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the non-conflicting

[0034] Under certain circumstances, the following embodiments and the features in the embodiments can be combined with each other.

[0035] The present invention is described below by taking the motor of a double-roller compressor as an example:

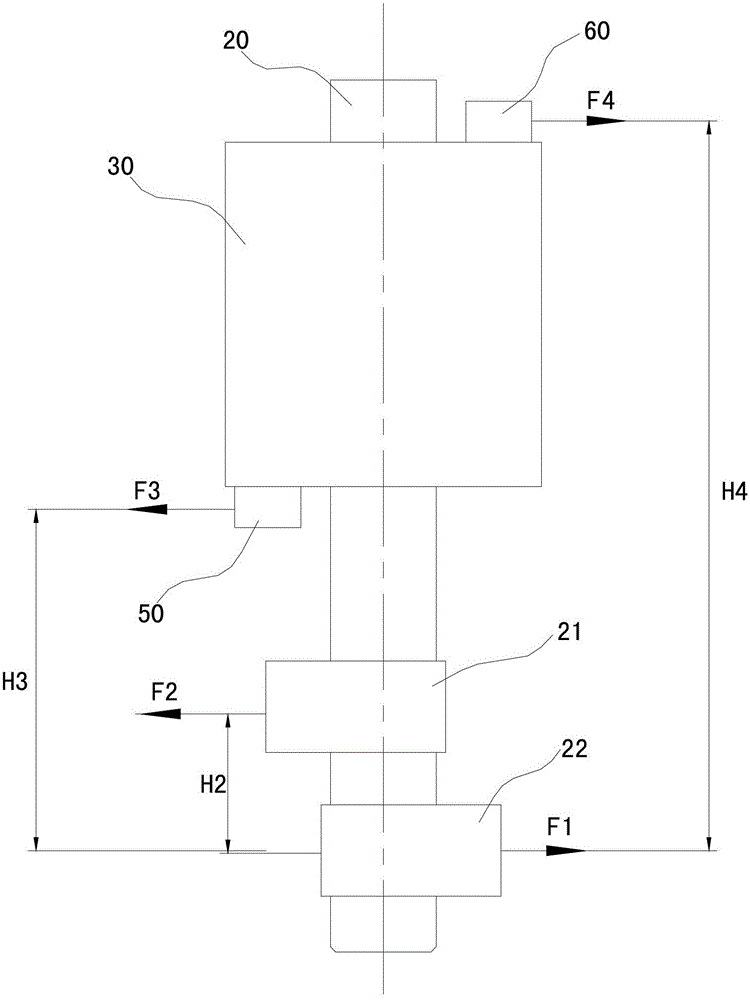

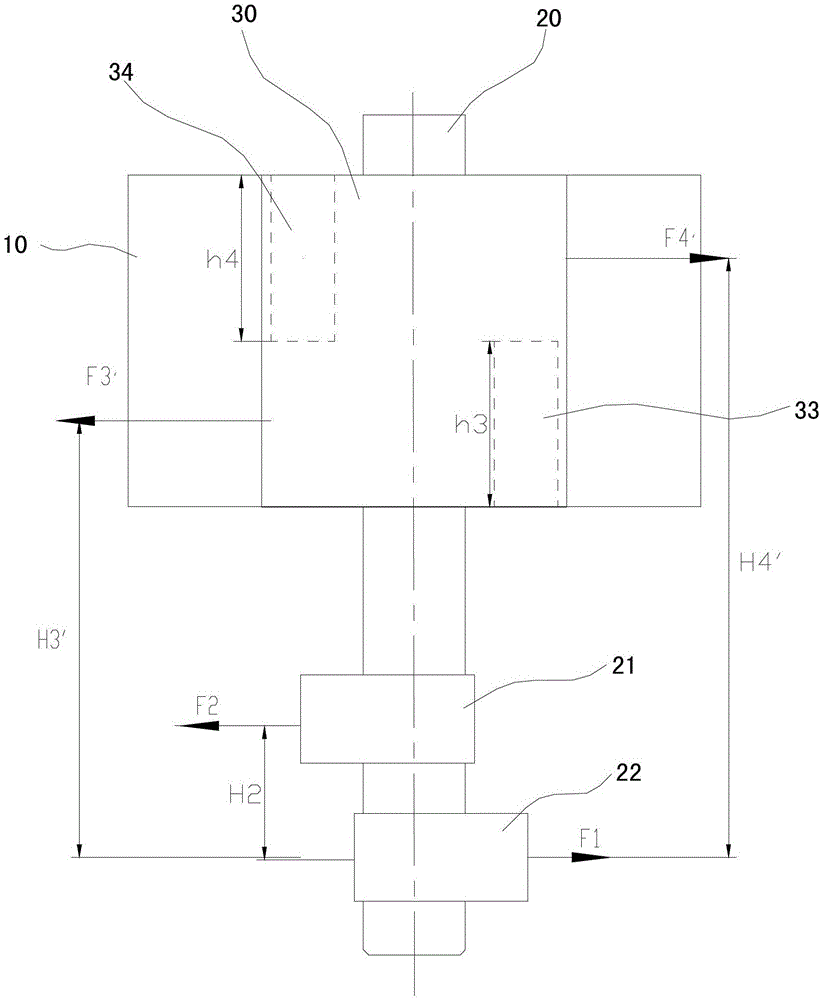

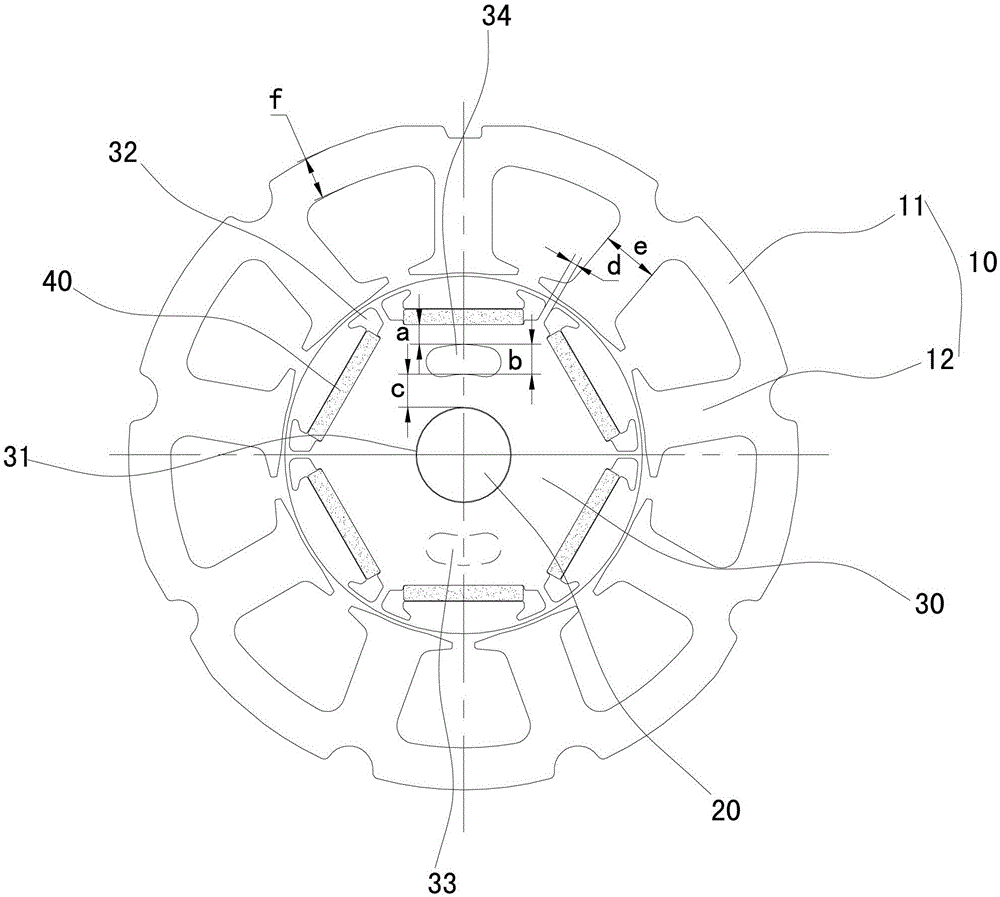

[0036] Such as figure 1 and figure 2 As shown, the motor of the double-roller compressor includes a stator and a rotor, wherein the stator includes a stator core 10 having an annular stator yoke 11 and protruding radially inward from the stator yoke 11 A plurality of stator teeth 12. The rotor has a rotor core 30 and a rotating shaft 20, the rotor core 30 has a shaft hole 31, a plurality of permanent magnet holes 32, one or more main counterweight holes 33 and one or more auxiliary counterweight holes 34, The rotating shaft 20 is installed in the shaft hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com