DC plug metal contact and metal contact flat cable capable of automatically crimping

A metal contact and plug technology, applied in contact parts, contact manufacturing, riveting connection, etc., can solve the problems of affecting the performance of DC plugs, uneven solder joint size, low production efficiency, etc., to avoid poor welding, improve Production efficiency, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

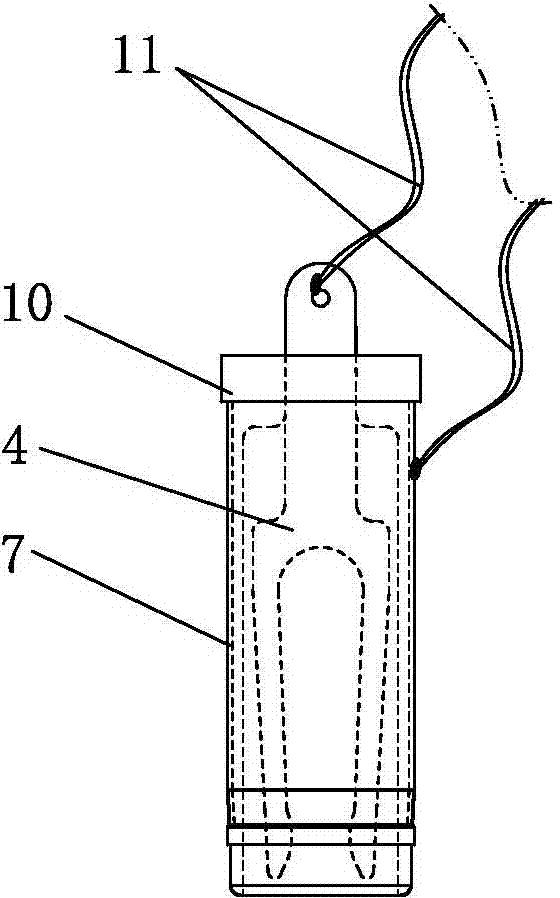

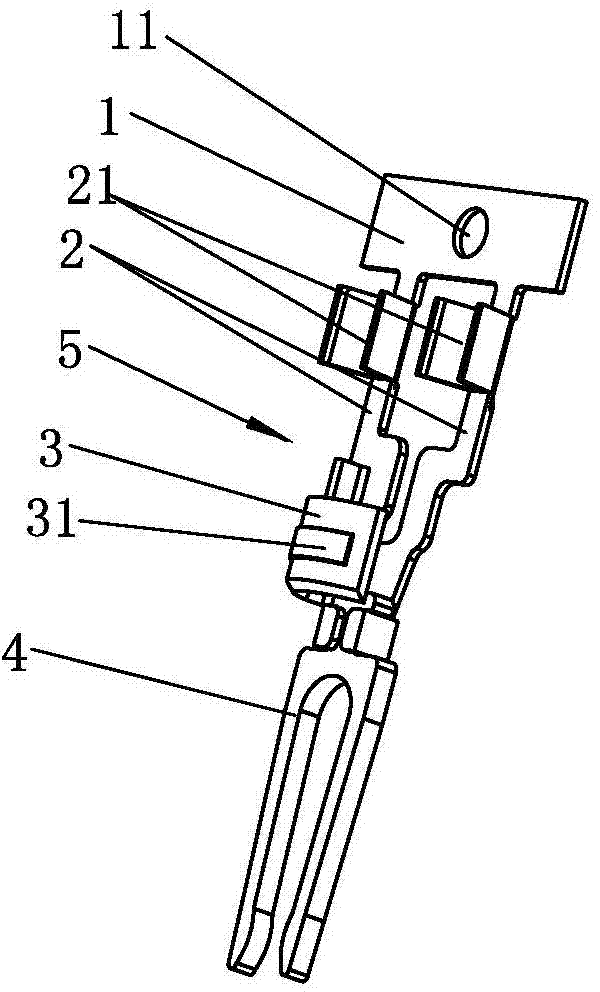

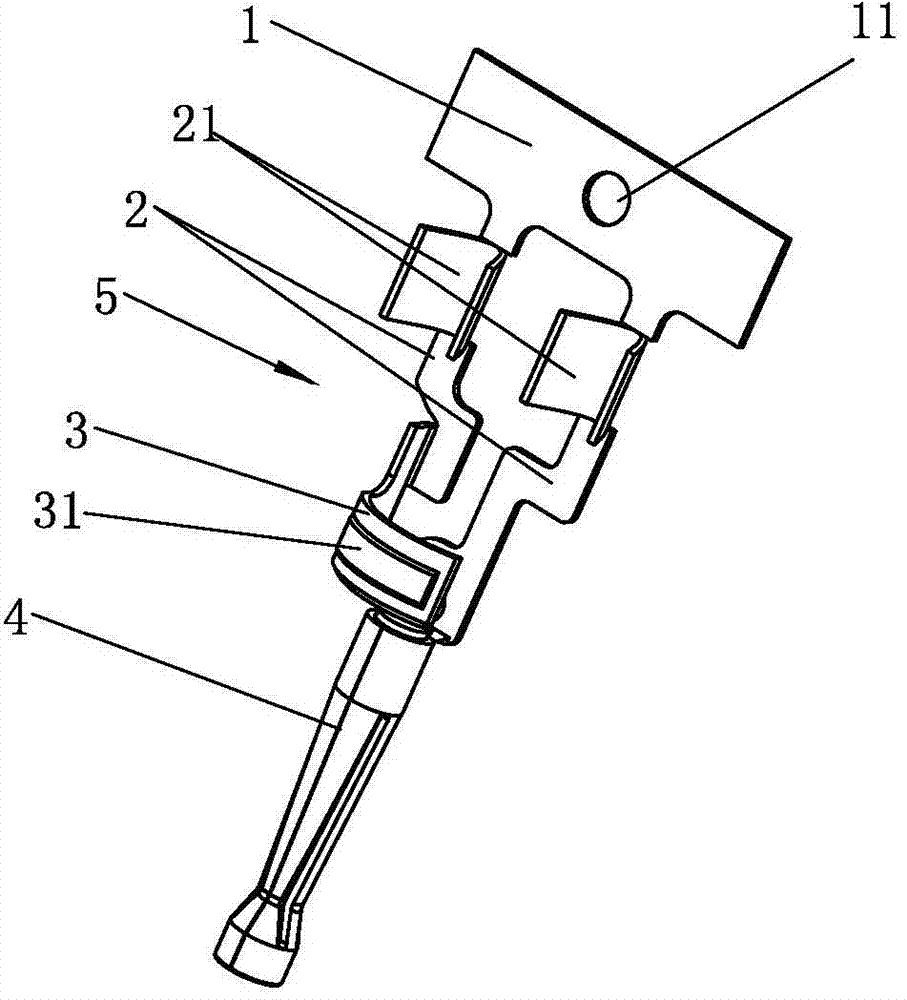

[0021] Attached below Figure 2-8 The present invention is described further:

[0022] A DC plug metal contact for automatic termination, the metal contact 5 includes a horizontal connecting piece 1, two connecting pieces 2 are arranged vertically to the same side on the horizontal connecting piece 1, and the end of a connecting piece 2 is set for With the semi-annular contact piece 3 connected to the metal conduit 7, the inner elastic contact piece 4 is arranged at the end of the other connecting piece 2, and the semi-annular contact piece 3 is arranged in the shape of surrounding the inner elastic contact piece 4, and the connecting piece 2 is in the A wire riveting position 21 is set close to the position of the transverse connecting piece 1 .

[0023] In order to save costs and adapt to automatic production, the inner elastic contact piece 4 is riveted on the end of the connecting piece 2. Through two different materials, the inner elastic contact piece 4 is thicker than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com